配件详情

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE523502、RE518520、RE68345、RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE521538、RE521540、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960

麦克福斯约翰迪尔发动机零配件

|

|

|

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE521616 排放 2 & 3

|

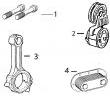

|

||||||||||||||||||||||||||||

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)曲轴加工过程中必须保持适当的轴承轴颈半径,以保证正确的操作。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)检查应用程序是否正确使用。

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

型号 数量 描述

TR114082 6 连杆衬套 PT 41 mm

TR119874 1 凸轮轴衬套

TR501124 12 连杆螺钉

TRE31617 12 气门密封 STEM LITER ENG

TRE44574 1 前油封

TRE505515 1 后油封

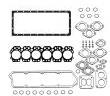

TRE532631 1 大修包

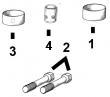

TRE536083 6 活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 (RE527039) 2V

TRE65165 6 主轴瓦(标准)

TRE65168 1 止推瓦(标准)

TRE65908 6 连杆瓦(标准

发动机内部修理套件

型号 数量 描述

TR114082 6 连杆衬套 PT 41 mm

TR119874 1 凸轮轴衬套

TR501124 12 连杆螺钉

TRE31617 12 气门密封 STEM LITER ENG

TRE44574 1 前油封

TRE505515 1 后油封

TRE532631 1 大修包

TRE536083 6 活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 (RE527039) 2V

TRE65165 6 主轴瓦(标准)

TRE65168 1 止推瓦(标准)

TRE65908 6 连杆瓦(标准)

component technical manual deere power systems group ctm100 (20mar01) litho in u.s.a. english powertech diesel engines base engine for complete service information also see: powertech 10.5 l & 12.5 l diesel with lucas euis ctm188 alternators&starter motors ctm77 10.5 l & 12.5 l engines lucus electronic fuel systems with lucas euis ctm115 powertech 10.5 l & 12.5 l diesel engines level 6 electronic fuel systems oem engine acces ies ctm67 (english only) introduction rg,rg34710,1 –19–11oct00–1/1 forward this manual is written for an experienced technician. essential tools required in performing certain service work are identified in this manual&are recommended for use. this manual (ctm100) covers only the base engine. it is one of three volumes on 10.5 l&12.5 l engines. the following two companion manuals cover electronic fuel system repair, operation&diagnostics: ? ctm115—lucas electronic fuel systems with lucas euis ? ctm188—level 6 electronic fuel systems with lucas euis ctm115&ctm188 will cover fuel system repair, formerly included in ctm100, groups 35&36. other manuals will be added in the future to provide added information on new electronic fuel systems. a complete set of all three manuals covering the 10.5 l&12.5 l engines can be procured by ordering ctm650 binder set. live with safety: read the safety messages in the introduction of this manual&the cautions presented throughout the text of the manual. this is the safety-alert symbol. when you see this symbol on the machine/in this manual, be alert to the potential for personal injury. use this component technical manual in conjunction with the machine technical manual. an application listing in section 01, group 001 identifies product-model/component type-model relationship. information is organized in sections&groups for the various components requiring service instruction. at the end of this manual are summary listings of all applicable essential tools, service equipment&tools, other materials needed to do the job, service parts kits, specifications, wear tolerances,&torque values. before beginning repair on an engine, clean the engine and mount on a repair stand. (see section 2, group 010.) this manual contains si metric units of measure followed immediately by the u.s. customary units of measure. most hardware on these engines is metric. some components of this engine may be serviced without removing the engine from the machine. refer to the specific machine technical manual for information on this&for engine removal and installation procedures. read each block of material completely before performing service to check for differences in procedures/specifications. follow only the procedures that apply to the engine model number you are working on. if only one procedure is given, that procedure applies to all the engines in the manual. california proposition 65 warning diesel engine exhaust&some of its constituents are known to the state of california to cause cancer, birth defects&other reproductive harm. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=2 introduction ouo1004,0000bbc –19–11oct00–1/2 john deere dealers the changes listed below make your ctm obsolete. repair, operation&diagnostics on 10.5 l&12.5 l diesel engines is now covered in three manuals. fuel system repair has been removed from ctm100 and incorporated into its two companion manuals.discard ctm100 dated 09nov99 and replace with the following new manuals. ? ctm100—10.5 l&12.5 l diesel engines—base engine ? ctm115—10.5 l&12.5 l diesel engines—lucas electronic fuel systems with lucas euis ? ctm188—10.5 l&12.5 l diesel engines—level 6 electronic fuel systems with lucas euis also, copy these pages listing changes&route through your service department. section 01, group 000 (safety) ? updated safety information. section 01, group 001 (engine identification) ? updated engine model designation chart. ? updated engine application charts. section 01, group 002 (fuels, lubricants and coolants) ? updated engine oil&coolant application guidelines. section 02, group 010 (engine rebuild) ? updated sealant application guidelines. section 02, group 020 (cylinder head and valves) ? revised procedure for adjusting valves&injector preload. ? revised procedure for repair of crankcase ventilation assembly. ? revised valve guide specifications. ? revised procedure for installation of rocker arm assembly. section 02, group 030 (cylinder block, liners, pistons&rods) ? added additional information on inspecting pistons to include specifications on new 12.5 l pistons. ? deleted requirement for sealant on front plate gasket. ? revised cylinder liner manufacturer data codes. ? revised procedure for disassembly&assembly of pistons&rods to include new piston ring and piston protrusion specifications. section 02, group 040 (crankshaft, main bearings&flywheel) ? revised procedure for installation of timing gear cover&camshaft gear access cover to include new sealing instructions. ? revised procedure for inspection of vibration damper. ? added torque specifications for flywheel housing. ? added procedure for main bearing failure analysis. section 02, group 050 (camshaft&timing gear train) ? revised camshaft lobe lift specifications. ? revised procedure for adjustment of camshaft-to-crankshaft timing. ? revised procedure for installation of camshaft. ? revised procedure for installation of auxiliary drive. section 02, group 060 (lubrication system) ? revised procedure for sealing oil pan mating surfaces. section 02, group 070 (cooling system) ? revised repair procedure for coolant pump (no longer serviceable). ? revised fan drive hub torque specification. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=3 introduction ouo1004,0000bbc –19–11oct00–2/2 section 02, group 080 (air intake&exhaust system) ? added new test specifications for borg warner turbocharger. ? revised procedure for removal&installation of air intake manifold. section 02—group 090&091(fuel system) note: repair procedures for fuel systems has been moved to the following manuals: ? ctm115—lucas electronic fuel systems with lucas euis, section 02, group 090 ? ctm188—level 6 electronic fuel systems with lucas euis, section 02, group 090 (dual rail system)&group 091 (single rail system) section 02—group 110 (electrical engine control) note: repair procedures for electrical engine control components has been moved to section 02, group 110 of the following manuals: ? ctm115—lucas electronic fuel systems with lucas euis ? ctm188—level 6 electronic fuel systems with lucas euis section 02—group 100 (starting&charging systems) ? starting&charging systems are now covered 益阳强鹿活塞环RE515941价格哪家好,滁州约翰迪尔6068大修包厂家供应,武威约翰迪尔强鹿皮带张紧轮RE68715价格,新乡约翰迪尔拖拉机发动机缸盖批发商,和田强鹿柴油发动机缸套水封圈AR98850价格,来宾约翰迪尔强鹿曲轴总成代理,宿州JohnDeere衬垫套RE528402价格,新界约翰迪尔联合收割机发动机柱塞一级代理,开封强鹿4045柴油机气门室盖垫片价格行情,鹤岗约翰迪尔强鹿4045柴油机配件活塞缸套组件厂家价格,昭通JohnDeere传感器RE167207厂家价格,揭阳JohnDeere发动机RE65165主轴瓦代理商,海西约翰迪尔6090柴油机凸轮轴厂家供货,伊犁JOHNDEERE充电机RE506196市场报价,沈阳约翰迪尔强鹿3029el36936喷油器诚信推荐,锦州约翰迪尔挖掘机仪表盘一级代理,杭州强鹿柴滤RE59754哪家买,广元约翰迪尔6081发动机曲轴齿轮价格,双鸭山约翰迪尔6068柴油机曲轴齿轮厂家供货,七台河约翰迪尔强鹿气门室盖垫片R524468哪里买,阜阳强鹿柴滤RE506428代理商,三亚约翰迪尔拖拉机发动机曲轴代理商,淮北约翰迪尔空气加热器RE502668批发价,郑州约翰迪尔强鹿7930拖拉机RE541925油水分离燃油滤清器的价格,金昌美国JohnDeere柴滤RE532952公司,绥化约翰迪尔强鹿R97490厂家供应,鹤岗JOHNDEERE强鹿6068TF275配件供货商,蚌埠约翰迪尔手动油泵RE68435厂家供应,甘南JohndeereCD3029水泵找哪家,通辽强鹿柴油滤芯AR86745厂家供货,四平约翰迪尔装载机发动机配件多少钱,金昌JohnDeere后齿轮R63326厂家批发,西双版纳约翰迪尔6068柴油机后油封供货商,钦州强鹿发动机充电机RE501634供应商,香港岛强鹿RE44574曲轴后油封找哪家,抚州强鹿柴油发动机维修配件厂家批发,茂名强鹿机油底壳垫片R532464市场报价,徐州强鹿4045柴油机节温器价格,揭阳强鹿JOHNDEERE柴油机喷油器RE522542厂家供应,肇庆强鹿约翰迪尔涡轮增压器找哪家,贵港强鹿曲轴瓦RE65165代理商,西双版纳约翰迪尔6068柴油机后油封一级代理,甘南JohndeereCD3029水泵一级代理,襄阳强鹿柴滤RE520842代理,宜昌Johndeere4039DF008AR97708哪里买,香港岛强鹿RE44574曲轴后油封批发价,中山约翰迪尔强鹿气门油封RE529187公司,九江强鹿RE538097曲轴前油封哪家好,商洛约翰迪尔缸套R116236批发价,海南约翰迪尔挖掘机柱塞代理商,咸宁JohnDeere柴油机活塞RE529264代理商,双鸭山JohnDeere缸套阳水圈AR65507厂家供货,丹东强鹿RE27368主轴瓦一级代理,乐山强鹿RE561742量油尺、厂家价格,曲靖强鹿柴油机RE521348曲轴价格,遵义强鹿柴油机3029连杆批发商,德宏约翰迪尔柴油机曲轴位置传感器RA519144厂家供应,广安强鹿柴油机4045主轴瓦供货商,长沙约翰迪尔甘蔗机发动机配件供货商,咸阳约翰迪尔强鹿连杆螺丝R501035价格,in this new section/group. section 03—group 120 (base engine operation) ? base engine theory of operation is covered in this new section/group. note: fuel system theory of operation has been moved to section 03, group 130 of the following manuals: ? ctm115—lucas electronic fuel systems with lucas euis ? ctm188—level 6 electronic fuel systems with lucas euis section 04—group 150 (observable diagnostics and tests) ? base engine observable tests&diagnostics is covered in this new section/group. ? added dynamometer test procedure. note: fuel system testing&diagnostics has been moved to section 04, group 150 in two other technical manuals: ctm115—lucas electronic fuel systems with lucas euis&ctm188— level 6 electronic fuel systems with lucas euis. section 5 (tools&other materials) ? all essential tools, service tools, dealer fabricated tools&other materials listed throughout this manual are consolidated in this section for ease of reference. section 6 (specifications) ? all repair, test&diagnostic specifications listed throughout this manual are consolidated in this section for ease of reference. ? revised dynamometer&turbocharger boost specification tables. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=4 introduction rg,rg34710,3 –19–06nov00–1/1 powertech? 6105hf&6125hf engines rg9030 –un–21may98 right side view (early engine) rg9031 –un–21may98 left side view (early engine) rg9032 –un–21may98 3/4 right front view (early engine) rg9033 –un–21may98 3/4 left front view (early engine) powertech is a registered trademark of deere & company. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=5 introduction dpsg,ouo1004,915 –19–16nov00–1/1 powertech? 6105hf&6125hf engines—continued rg11174 –un–20nov00 3/4 right rear view (early engine) rg11175 –un–20nov00 3/4 left rear view (early engine) rg11171a –un–03nov00 right side view later engine s.n. (30000— ) rg11172a –un–04dec00 3/4 right front view later engine s.n. (30000— ) powertech is a registered trademark of deere & company. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=6 introduction rg,rg34710,3a –19–30sep97–1/1 powertech? 6105hrw&6125hrw engines rg8222 –un–21may98 right side view rg8221 –un–21may98 left side view rg8223 –un–21may98 3/4 right front view rg8224 –un–21may98 3/4 left front view powertech is a registered trademark of deere & company. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=7 introduction dpsg,ouo1004,916 –19–30jun99–1/1 powertech? 6105hrw&6125hrw engines—continued rg8220 –un–21may98 3/4 right rear view rg8219 –un–21may98 3/4 left rear view powertech is a registered trademark of deere & company. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=8 introduction rg,rg34710,5 –19–30sep97–1/1 powertech? 6105adw engine rg8454 –un–21may98 right side view rg8448 –un–21may98 3/4 left front view rg8453 –un–21may98 3/4 right rear view rg8451 –un–21may98 3/4 left rear view powertech is a registered trademark of deere & company. ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=9 introduction rg,rg34710,8 –19–30sep97–1/1 6105&6125 engine cutaway view rg8435 –un–12jul99 engine cutaway view a—oil cooler e—crankshaft i—piston rings m—valves b—oil pump drive gear f—cylinder liner j—connecting rod n—electronic unit injector c—idler gear g—cylinder liner o-rings k—oil spray jet o—two-piece rocker arm d—camshaft gear h—piston l—camshaft shaft ctm100 (20mar01) powertech 10.5 l & 12.5 l diesel engines 032001 pn=10 contents 01 section 01—general information group 000—safety group 001—engine identification group 002—fuels, lubricants&coolant 02 section 02—repair&adjustments group 010—engine rebuild guide, break-in and tune-up group 020—cylinder head&valves group 030—cylinder block, liners, pistons, and rods group 040—crankshaft, main bearings, and flywheel group 050—camshaft&timing gear train group 060—lubrication system group 070—cooling system 03 group 080—air intake&exhaust system group 090—fuel system group 100—starting&charging systems section 03—theory of operation group 120—base engine operation section 04—diagnostics group 150—observable diagnostics&tests section 05—tools&other materials 04 group 170—repair tools&other materials group 180—diagnostic service tools group 190—dealer fabricated service tools section 06—specifications group 200—repair&general oem specifications group 210—diagnostic specifications 05 all information, illustrations&specifications in this manual are based on the latest information available at the time of publication. the right is reserved to make changes at any time without notice. 06 copyright ? 2001 deere & company moline, illinois all rights reserved a john deere illustruction? manual previous editions copyright ? 1996, 1997, 1999 indx ctm100 (20mar01) i powertech 10.5 l & 12.5 l diesel engines 032001 pn=1 contents 01 02 03 04 05 06 indx ctm100 (20mar01) ii powertech 10.5 l & 12.5 l diesel engines 032001 pn=2 01 section 01 general information contents page group 000—safety 01-000-1 group 001—engine identification engine model designation 01-001-1 engine serial number plate information 01-001-2 engine option code label 01-001-3 engine application chart 01-001-4 group 002—fuels, lubricants&coolant diesel fuel 01-002-1 bio-diesel fuel 01-002-2 lubricity of diesel fuel 01-002-4 dieselscan? fuel analysis 01-002-4 engine break-in oil 01-002-5 diesel engine oil 01-002-6 extended diesel engine oil service intervals 01-002-6 alternative&synthetic lubricants 01-002-7 mixing of lubricants 01-002-7 oilscan&coolscan 01-002-8 grease 01-002-9 diesel engine coolant 01-002-10 diesel engine coolants, supplemental additive information 01-002-11 testing diesel engine coolant 01-002-12 suppemental coolant additives 01-002-13 replenishing supplemental coolant additives (scas) between coolant changes 01-002-14 operating in warm temperature climates 01-002-15 flush&service cooling system 01-002-16 disposing of coolant 01-002-17 ctm100 (20mar01) 01-1 powertech 10.5 l & 12.5 l diesel engines 032001 pn=1 contents 01 ctm100 (20mar01) 01-2 powertech 10.5 l & 12.5 l diesel engines 032001 pn=2 group 000 safety 01 000 1 dx,flame –19–29sep98–1/1 handle fluids safely—avoid fires ts227 –un–23aug88 avoid fires when you work around fuel, do not smoke/work near heaters/other fire hazards. store flammable fluids away from fire hazards. do not incinerate/puncture pressurized containers. make sure machine is clean of trash, grease,&debris. do not store oily rags; they can ignite&burn spontaneously. dx,rcap –19–04jun90–1/1 service cooling system safely ts281 –un–23aug88 explosive release of fluids from pressurized cooling system can cause serious burns. shut off engine. only remove filler cap when cool enough to touch with bare hands. slowly loosen cap to first stop to relieve pressure before removing completely. dx,fire2 –19–03mar93–1/1 prepare for emergencies ts291 –un–23aug88 first aid kit be prepared if a fire starts. keep a first aid kit&fire extinguisher handy. keep emergency numbers for doctors, ambulance service, hospital,&fire department near your telephone. ctm100 (20mar01) 01-000-1 powertech 10.5 l & 12.5 l diesel engines 032001 pn=15 safety 01 000 2 dpsg,ouo1004,2758 –19–11may00–1/1 handling batteries safely ts204 –un–23aug88 explosion ts203 –un–23aug88 acid caution: battery gas can explode. keep sparks&flames away from batteries. use a flashlight to check battery electrolyte level. never check battery charge by placing a metal object across the posts. use a voltmeter or hydrometer. always remove grounded (-) battery clamp first and replace it last. caution: sulfuric acid in battery electrolyte is poisonous. it is strong enough to burn skin, eat holes in clothing,&cause blindness if splashed into eyes. avoid the hazard by: 1. filling batteries in a well-ventilated area. 2. wearing eye protection&rubber gloves. 3. avoiding breathing fumes when electrolyte is added. 4. avoiding spilling/dripping electrolyte. 5. use proper jump start procedure. if you spill acid on yourself: 1. flush your skin with water. 2. apply baking soda/lime to help neutralize the acid. 3. flush your eyes with water for 15—30 minutes. get medical attention immediately. if acid is swallowed: 1. do not induce vomiting. 2. drink large amounts of water/milk, but do not exceed 2 l (2 quarts). 3. get medical attention immediately. warning: battery posts, terminals,&related acces ies contain lead&lead compounds, chemicals known to the state of california to cause cancer and reproductive harm. wash hands after handling. ctm100 (20mar01) 01-000-2 powertech 10.5 l & 12.5 l diesel engines 032001 pn=16 safety 01 000 3 dx,fluid –19–03mar93–1/1 avoid high-pressure fluids x9811 –un–23aug88 high-pressure fluids escaping fluid under pressure can penetrate the skin causing serious injury. avoid the hazard by relieving pressure before disconnecting hydraulic/other lines. tighten all connections before applying pressure. search for leaks with a piece of cardboard. protect hands and body from high pressure fluids. if an accident occurs, see a doctor immediately. any fluid injected into the skin must be surgically removed within a few hours/gangrene may result. doctors unfamiliar with this type of injury should reference a knowledgeable medical source. such information is available from deere & company medical department in moline, illinois, u.s.a. dx,wear –19–10sep90–1/1 wear protective clothing ts206 –un–23aug88 protective clothing wear close fitting clothing&safety equipment appropriate to the job. prolonged exposure to loud noise can cause impairment or loss of hearing. wear a suitable hearing protective device such as earmuffs/earplugs to protect against objectionable or文山johndeere约翰迪尔强鹿柴油发动机废气热交换器RE521493厂家价格,新乡约翰迪尔水泵垫片R123417哪家买,聊城约翰迪尔缸套水封圈AR98850信息,厦门强鹿柴油滤RE62418厂家价格,广元强鹿柴油机进排气门座圈哪家好,阿勒泰约翰迪尔E210LC挖掘机机油冷却器批发商,崇左JohnDeere柴油机主轴瓦RE529319哪家好,山南约翰迪尔柴油发电机组单体泵哪里买, uncomfortable loud noises. operating equipment safely requires the full attention of the operator. do not wear radio/music headphones while operating machine. ctm100 (20mar01) 01-000-3 powertech 10.5 l & 12.5 l diesel engines 032001 pn=17 safety 01 000 4 dx,loose –19–04jun90–1/1 service engines safely ts228 –un–23aug88 moving parts tie long hair behind your head. do not wear a necktie, scarf, loose clothing,/necklace when you work near engine tools/moving parts. if these items were to get caught, severe injury could result. remove rings&other jewelry to prevent electrical shorts&entanglement in moving parts. dx,air –19–17feb99–1/1 work in ventilated area ts220 –un–23aug88 engine exhaust fumes engine exhaust fumes can cause sickness/death. if it is necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. if you do not have an exhaust pipe extension, open the doors&get outside air into the area ctm100 (20mar01) 01-000-4 powertech 10.5 l & 12.5 l diesel engines 032001 pn=18 safety 01 000 5 dx,clean –19–04jun90–1/1 work in clean area t6642ej –un–18oct88 clean work area before starting a job: ? clean work area&machine. ? make sure you have all necessary tools to do your job. ? have the right parts on hand. ? read all instructions thoroughly; do not attempt shortcuts. dx,paint –19–22oct99–1/1 remove paint before welding/heating ts220 –un–23aug88 toxic fumes avoid potentially toxic fumes&dust. hazardous fumes can be generated when paint is heated by welding, soldering,/using a torch. remove paint before heating: ? remove paint a minimum of 76 mm (3 in.) from area to be affected by heating. ? if you sand/grind paint, avoid breathing the dust. wear an approved respirator. ? if you use solvent/paint stripper, remove stripper with soap&water before welding. remove solvent or paint stripper containers&other flammable material from area. allow fumes to disperse at least 15 minutes before welding/heating. do all work in an area that is ventilated to carry toxic fumes&dust away. dispose of paint&solvent properly. ctm100 (20mar01) 01-000-5 powertech 10.5 l & 12.5 l diesel engines 032001 pn=19 safety 01 000 6 dx,torch –19–03mar93–1/1 avoid heating near pressurized fluid lines ts953 –un–15may90 flammable spray flammable spray can be generated by heating near pressurized fluid lines, resulting in severe burns to yourself&bystanders. do not heat by welding, soldering,/using a torch near pressurized fluid lines or other flammable materials. pressurized lines can be accidentally cut when heat goes beyond the immediate flame area. dx,light –19–04jun90–1/1 illuminate work area safely ts223 –un–23aug88 work area safely illuminate your work area adequately but safely. use a portable safety light for working inside/under the machine. make sure the bulb is enclosed by a wire cage. the hot filament of an accidentally broken bulb can ignite spilled fuel/oil. ctm100 (20mar01) 01-000-6 powertech 10.5 l & 12.5 l diesel engines 032001 pn=20 safety 01 000 7 dx,lift –19–04jun90–1/1 use proper lifting equipment ts226 –un–23aug88 proper lifting equipment lifting heavy components incorrectly can cause severe injury/machine damage. follow recommended procedure for removal and installation of components in the manual. dpsg,ouo1004,899 –19–19may99–1/1 construct dealer-made tools safely lx1016749 –un–01jul97 construct dealer-made tools safely faulty/broken tools can result in serious injury. when constructing tools, use proper, quality materials&good workmanship. do not weld tools unless you have the proper equipment and experience to perform the job. ctm100 (20mar01) 01-000-7 powertech 10.5 l & 12.5 l diesel engines 032001 pn=21 safety 01 000 8 dx,serv –19–17feb99–1/1 practice safe maintenance ts218 –un–23aug88 keep area clean understand service procedure before doing work. keep area clean&dry. never lubricate, service,/adjust machine while it is moving. keep hands, feet ,&clothing from power-driven parts. disengage all power&operate controls to relieve pressure. lower equipment to the ground. stop the engine. remove the key. allow machine to cool. securely support any machine elements that must be raised for service work. keep all parts in good condition&properly installed. fix damage immediately. replace worn/broken parts. remove any buildup of grease, oil,/debris. on self-propelled equipment, disconnect battery ground cable (-) before making adjustments on electrical systems or welding on machine. on towed implements, disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine. dx,repair –19–17feb99–1/1 use proper tools ts779 –un–08nov89 proper tools use tools appropriate to the work. makeshift tools and procedures can create safety hazards. use power tools only to loosen threaded parts and fasteners. for loosening&tightening hardware, use the correct size tools. do not use u.s. measurement tools on metric fasteners. avoid bodily injury caused by slipping wrenches. use only service parts meeting john deere specifications. ctm100 (20mar01) 01-000-8 powertech 10.5 l & 12.5 l diesel engines 032001 pn=22 safety 01 000 9 dx,drain –19–03mar93–1/1 dispose of waste properly ts1133 –un–26nov90 recycle waste improperly disposing of waste can threaten the environment&ecology. potentially harmful waste used with john deere equipment include such items as oil, fuel, coolant, brake fluid, filters,&batteries. use leakproof containers when draining fluids. do not use food/beverage containers that may mislead someone into drinking from them. do not pour waste onto the ground, down a drain,/into any water source. air conditioning refrigerants escaping into the air can damage the earth’s atmosphere. government regulations may require a certified air conditioning service center to recover&recycle used air conditioning refrigerants. inquire on the proper way to recycle/dispose of waste from your local environmental/recycling center,/from your john deere dealer. dx,live –19–25sep92–1/1 live with safety ts231 –19–07oct88 safety systems before returning machine to customer, make sure machine is functioning properly, especially the safety systems. install all guards&shields. ctm100 (20mar01) 01-000-9 powertech 10.5 l & 12.5 l diesel engines 032001 pn=23 safety 01 000 10 ctm100 (20mar01) 01-000-10 powertech 10.5 l & 12.5 l diesel engines 032001 pn=24 group 001 engine identification 01 001 1 rg,rg34710,23 –19–11oct00–1/1 engine model designation rg8427 –un–21may98 engine serial number plate example: john deere engine model—6105hrw01 john deere engine model designation includes number of cylinders, displacement in liters, aspiration, user code, and application code. for example: 6105hrw01 engine 6 number of cylinders 10.5 . liter designation h . aspiration rw user code 01 . application code aspiration code a turbocharged&air-to-coolant aftercooled h . turbocharged&air-to-air aftercooled user code dw davenport (heavy-duty industrial) works f oem rw waterloo (tractor) works t dubuque (construction equipment) works t8 . cameco z . zweibrucken (forage harvester) works application code 01, 02, etc., code for specific application ctm100 (20mar01) 01-001-1 powertech 10.5 l & 12.5 l diesel engines 032001 pn=25 engine identification 01 001 2 rg,rg34710,24 –19–07nov00–1/1 engine serial number plate information rg8427a –un–09dec97 example engine serial number plate important: the engine serial number plate can be easily destroyed. remove the plate or record the information elsewhere, before “hot tank” cleaning the block. 1. example engine serial number (a) each engine has a 13-digit john deere engine serial number identifying the producing factory, engine model designation,&a 6-digit sequential number. the following is an example: rg6105h000000 rg factory code producing engine 6105h . engine model designation 000000 sequential number factory code producing engine rg . waterloo engine works engine model designation 6105h . see engine model designation on previous page sequential number 000000 6-digit sequential number 2. engine application data (b) the second line of information on the engine serial number plate identifies the engine/deere machine or oem relationship. see engine application chart later in this group. ctm100 (20mar01) 01-001-2 powertech 10.5 l & 12.5 l diesel engines 032001 pn=26 engine identification 01 001 3 dpsg,ouo1004,917 –19–30jun99–1/1 engine option code label rg8740 –un–12jul99 option code label in addition to the serial number plate, oem engines have an engine option code label affixed to the rocker arm cover. these codes indicate which of the engine options were installed on your engine at the factory. when in need of parts/service, furnish your authorized servicing dealer/engine distributor with these numbers. ctm100 (20mar01) 01-001-3 powertech 10.5 l & 12.5 l diesel engines 032001 pn=27 engine identification 01 001 4 rg,rg34710,25 –19–11oct00–1/1 engine application chart john deere agricultural equipment applications machine model no. engine model tractors—4-wheel drive 9200 6105hrw01, 6125hrw02, 6125hrw05 (30000— ) 9300 6125hrw01, 6125hrw11, 6125hrw07 (30000— ) 9400 6125hrw02, 6125hrw12, 6125hrw09 (30000— ) tractors—ltv tracks 9300t . 6125hrw03, 6125hrw06 (30000— ) 9400t . 6125hrw04, 6125hrw08 (30000— ) forage harvesters — self-propelled 6750 6125hz002, 6125hz006 6850 6125hz001, 6125hz005 cane harvester (cameco) ch2500 6125at801 john deere construction equipment application machine model no. engine model 744h loader—4-wheel drive 6125adw01 744h/mh log loader . 6125adw01, 6125hdw01 (30000— ) 230lc excavator 6125adw70 450lc dozer . 6125ht001 (30000— ) original equipment manufacturers (oem) applications machine model no. engine model oem . 6105af001 6105hf001 6125af001 6125afm01 6125hf001 6125hf070 (30000— ) ctm100 (20mar01) 01-001-4 powertech 10.5 l & 12.5 l diesel engines 032001 pn=28 group 002 fuels, lubricants&coolant 01 002 1 rg40854,0000027 –19–19mar01–1/1 diesel fuel consult your local fuel distributor for properties of the diesel fuel available in your area. in general, diesel fuels are blended to satisfy the low temperature requirements of the geographical area in which they are marketed. diesel fuels specified to en 590/astm d975 are recommended. in all cases, the fuel shall meet the following properties: cetane number of 40 minimum. cetane number greater than 50 is preferred, especially for temperatures below -20°c (-4°f)/elevations above 1500 m (5000 ft). cold filter plugging point (cfpp) below the expected low temperature/cloud point at least 5°c (9°f) below the expected low temperature. fuel lubricity should pass a minimum of 3100 gram load level as measured by the bocle scuffing test. sulfur content: ? sulfur content should not exceed 0.5%. sulfur content less than 0.05% is preferred. ? if diesel fuel with sulfur content greater than 0.5% sulfur content is used, reduce the service interval for engine oil&filter by 50%. ? do not use diesel fuel with sulfur content greater than 1.0%. do not mix used engine oil/any other type of lubricant with diesel fuel. ctm100 (20mar01) 01-002-1 powertech 10.5 l & 12.5 l diesel engines 032001 pn=29 fuels, lubricants&coolant 01 002 2 rg40854,0000028 –19–19mar01–1/2 bio-diesel fuel bio-diesel fuels may be used only if the fuel properties meet din 51606/equivalent specification. it has been shown that bio-diesel fuels have been found to improve lubricity in concentrations up to 5% blend in petroleum diesel fuel. when using a blend of bio-diesel fuel with fuel pumps, the oil level must be checked daily when the air temperature is -10° c (14° f)/lower. if oil becomes diluted with fuel, oil change intervals must be shortened accordingly. important: raw pressed vegetable oils are not acceptable for use for fuel in any concentration in john deere engines. these oils do not burn completely,&will cause engine failure by leaving deposits on injectors&in the combustion chamber. users of bio-diesel fuel should always remember that a major selling merit is its ability to biodegrade, so the storage&handling of this fuel is very important. this importance can be seen in the following areas of concern: ? the quality of the fresh fuel, ? water content of the fuel, ? problems due to aging of the fuel. potential problems resulting from deficiencies in the above areas when using bio-diesel fuel in concentrations above 5% may lead to the following symptoms: ? power loss&deterioration of performance, ? fuel leakage, ? corrosion of fuel injection equipment, ? coked/blocked injector nozzles, leading to poor atomization of fuel, ? filter plugging, ? lacquering/seizure of internal components, ? sludge&sediments, ? reduced service life. ctm100 (20mar01) 01-002-2 powertech 10.5 l & 12.5 l diesel engines 032001 pn=30 continued on next page fuels, lubricants&coolant 01 002 3 rg40854,0000028 –19–19mar01–2/2 bio-diesel property list for din 51606 property unit din 51606 sept 1997 density at 15° c (59° f) g/cm3 (lb/ft3) 0.875—0.900 (55—56) viscosity at 40° c (104° f) mm2/s (cst) 3.5—5.0 flash point °c (°f) min. 110 (230) cold filter plugging point—summer °c (°f) max. 0 (32) cold filter plugging point—winter °c (°f) max. -20 (-4) total sulfur % mass 0.01 conradson (ccr) at 100% % mass max. 0.05 cetane number — min. 49 ash content % mass max. 0.03 water content % mass max. 0.03 total contamination % mass max. 0.002 copper corrosion (3 hours, 50° c) (3 hours, degree of corrosion 1 122° f) neutralization value mg koh/g max. 0.5 methanol content % mass max. 0.3 monoglycerides % mass max. 0.8 diglycerides % mass max. 0.4 trigycerides % mass max. 0.4 free glycerine % mass max. 0.02 total glycerine % mass max. 0.25 iodine number — max. 115 phosphorus % mass max. 0.001 alkali content (na + k) % mass max. 0.0005 ctm100 (20mar01) 01-002-3 powertech 10.5 l & 12.5 l diesel engines 032001 pn=31 fuels, lubricants&coolant 01 002 4 dx,fuel5 –19–24jan00–1/1 lubricity of diesel fuel diesel fuel must have adequate lubricity to ensure proper operation&durability of fuel injection system components. diesel fuels for highway use in the united states and canada require sulfur content less than 0.05%. diesel fuel in the european union requires sulfur content less than 0.05%. experience shows that some low sulfur diesel fuels may have inadequate lubricity&their use may reduce performance in fuel injection systems due to inadequate lubrication of injection pump components. the lower concentration of aromatic compounds in these fuels also adversely affects injection pump seals and may result in leaks. use of low lubricity diesel fuels may also cause accelerated wear, injection nozzle erosion/corrosion, engine speed instability, hard starting, low power, and engine smoke. fuel lubricity should pass a minimum of 3100 gram load level as measured by the bocle scuffing test. astm d975&en 590 specifications do not require fuels to pass a fuel lubricity test. if fuel of low/unknown lubricity is used, add john deere premium diesel fuel conditioner (or equivalent) at the specified concentration. dx,fuel6 –19–06dec00–1/1乐山约翰迪尔连杆铜套R114082厂家供应,张家口强鹿曲轴RE534314厂家价格,镇江强鹿曲轴RE535300找哪家,吉安JohnDeereel36936喷油器哪家好,日喀则强鹿柴油滤芯P550135供应商,通化JohnDeere节温器RE540550诚信推荐,金昌强鹿6081柴油发动机前油封厂家价格,贺州约翰迪尔柴油机3029前油封公司,澳门离岛约翰迪尔凸轮轴铜衬套R87561公司,遂宁强鹿6068柴油机燃油输油泵厂家供应,丽水约翰迪尔1000拖拉机发动机配件代理商,辽阳强鹿R80033连杆螺丝哪家买,中山JohnDeere皮带张紧轮RE68715供应商,秦皇岛约翰迪尔柴油发电机组活塞环供货商,铁岭JohnDeere气门油封RE526519批发价,鸡西美国JohnDeere输油泵RE65265代理商,邵阳约翰迪尔强鹿3029柴油机节恒温器一级代理,绥化约翰迪尔挖掘机缸套批发价,马鞍山JohnDeere气门导管R527286信息,盐城约翰迪尔挖掘机发动机配件批发价,赤峰约翰迪尔发动机喷油嘴价格,松原强鹿柴油机曲轴前油封RE54073的价格,荆州强鹿滤清器RE506178厂家价格,商丘约翰迪尔3029柴油机滤清器RE60021公司,昭通约翰迪尔强鹿4045柴油机RE65168B止推轴承多少钱 dieselscan? fuel analysis dieselscan? is a john deere fuel sampling program to help you monitor the quality of your fuel source. it verifies fuel type, cleanliness, water content, suitability for cold weather operation,&if fuel is within astm specifications. check with your john deere dealer for availability of dieselscan kits. dieselscan is a trademark of deere & company ctm100 (20mar01) 01-002-4 powertech 10.5 l & 12.5 l diesel engines 032001 pn=32 fuels, lubricants&coolant 01 002 5 rg,02,dt7326 –19–22jul99–1/1 engine break-in oil the engine is ready for normal operation. however, extra care during the first 100 hours of operation will result in more satisfactory long-term engine performance&life. new engines are filled at the factory with john deere engine break-in oil. during the break-in period, add john deere engine break-in oil as needed to maintain the specified oil level. do not exceed 100 hours of operation with break-in oil. important: do not add makeup oil until the oil is below the add mark on dipstick. john deere engine break-in oil (ty22041) should be used to make up any oil consumed during the break-in period. the engine should be operated at heavy loads with minimal idling during the break-in period. if the engine has significant operating time at idle, constant speeds, and/or light load usage,/makeup oil is required in the first 100 hour period, a longer break-in period may be required. in these situations, an additional 100 hour break-in period is recommended using a new change of john deere engine break-in oil&a new john deere oil filter. change the oil&filter after the first 100 hours of operation of a new/rebuilt engine. after engine overhaul, fill the engine with john deere engine break-in oil. if john deere engine break-in oil is not available, use a diesel engine oil meeting one of the following during the first 100 hours of operation: ? api service classification ce ? acea specification e1 after the break-in period, use john deere plus-50? or other diesel engine oil as recommended in this manual. important: do not use john deere plus-50? oil or engine oils meeting api cg4, api cf4, acea e3,/acea e2 performance levels during the first 100 hours of operation of a new or rebuilt engine. these oils will not allow the engine to break-in properly. plus-50 is a registered trademark of deere & company. ctm100 (20mar01) 01-002-5 powertech 10.5 l & 12.5 l diesel engines 032001 pn=33 fuels, lubricants&coolant 01 002 6 dx,enoil –19–24jan00–1/1 diesel engine oil ts1661 –un–10oct97 diesel engine oil use oil viscosity based on the expected air temperature range during the period between oil changes. the following oil is preferred: ? john deere plus-50? the following oil is also recommended: ? john deere torq-gard supreme? other oils may be used if they meet one/more of the following: ? api service classification ch-4 ? api service classification cg-4 ? api service classification cf-4 ? acea specification e3 ? acea specification e2 multi-viscosity diesel engine oils are preferred. if diesel fuel with sulfur content greater than 0.5% is used, reduce the service interval by 50%. extended service intervals may apply when john deere preferred engine oils are used. consult your john deere dealer for more information. plus-50 is a registered trademark of deere & company. torq-gard supreme is a registered trademark of deere & company dx,enoil6 –19–10oct97–1/1 extended diesel engine oil service intervals when john deere plus-50? oil&the specified john deere filter are used, the service interval for engine oil&filter changes may be increased by 50%. if other than plus-50?oil&the specified john deere filter are used, change the engine oil&filter at the normal service interval. plus-50 is a registered trademark of deere & company ctm100 (20mar01) 01-002-6 powertech 10.5 l & 12.5 l diesel engines 032001 pn=34 fuels, lubricants&coolant 01 002 7 dx,alter –19–15jun00–1/1 alternative&synthetic lubricants conditions in certain geographical areas may require lubricant recommendations different from those printed in this manual. some john deere brand coolants&lubricants may not be available in your location. consult your john deere dealer to obtain information and recommendations. synthetic lubricants may be used if they meet the performance requirements as shown in this manual. the temperature limits&service intervals shown in this manual apply to both conventional&synthetic oils. re-refined base stock products may be used if the finished lubricant meets the performance requirements. dx,lubmix –19–18mar96–1/1 mixing of lubricants in general, avoid mixing different brands/types of oil. oil manufacturers blend additives in their oils to meet certain specifications&performance requirements. mixing different oils can interfere with the proper functioning of these additives°rade lubricant performance. consult your john deere dealer to obtain specific

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

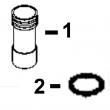

1 .. HOLDER NA X X

2 T24210 O-RING 6 X X

3 R76358 O-RING 1 X X

4 14M7272 NUT 3 X X M6

5 12M7006 LOCK WASHER 3 X X 0.236"

6 R67879 GASKET 1 X X

7 R53899 WASHER 1 X X

8 AR77114 CONTROL VALVE 1 X X

9 R53901 WASHER 1 X X

10 R63016 ADAPTER 1 X X

11 R67364 ELBOW FITTING 1 -087549 X X

RE502650 FITTING 1 087550- X X

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R126207 BRACKET 1 X X

2 14M7165 LOCK NUT 2 X X M6

3 RE53507 SOLENOID 1 X (A) (12 V) (SUB FOR RE54747)

4 19H1914 CAP SCREW 1 X X 1/4" X 1"

5 24H1287 WASHER 1 X X 9/32" X 5/8" X 0.065"

6 R98677 LEVER 1 X

RE54741 LEVER 1 X

7 03M7068 BOLT 1 X X M6 X 20

8 19H1900 CAP SCREW 2 X X 5/16" X 3/4"

9 24H1136 WASHER 2 X X 11/32" X 11/16" X 0.065"

10 R104592 PIPE PLUG 1 X X

11 R128694 BASE 1 X X (SUB FOR R127415) (ALSO ORDER (2)

R104592)

(A) ENERGIZE TO RUN

METTRE SOUS TENSION POUR FAIRE MARCHER

FUER BETRIEB AKTIVIEREN

ATTIVARE PER IL FUNZIONAMENTO

ACTIVAR PARA MARCHA

MAGNETISERA FOER ATT SAETTA IGAANG

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

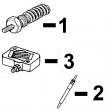

1 RE65265 HAND PRIMER 1 X X (SUB FOR RE48048)

2 R54025 WASHER 1 X X

3 R26448 O-RING 2 X X

4 RE10258 ELBOW FITTING 2 X (M14 X 5/8 IN.)

RE34128 ELBOW FITTING 1 X

RE10258 ELBOW FITTING 1 X

5 R67879 GASKET 1 X X

6 RE46375 FUEL PUMP 1 X X (ROBERT BOSCH)

7 51M4236 SEALING RING 1 X X

8 R83490 FITTING 1 X X