珀金斯2406J-E13TA零配件:发动机界的“六边形战士” Perkins 2406J-E13TA spare parts: the

一、走进珀金斯2406J-E13TA发动机

在工业领域,发动机堪称机械设备的“心脏”,其性能优劣直接关乎设备的运行效率与稳定性。珀金斯2406J-E13TA发动机作为行业内备受瞩目的一款产品,凭借出色表现,在众多应用场景中崭露头角。

在工程机械领域,无论是建筑工地上忙碌作业的挖掘机、装载机,还是道路施工中不可或缺的压路机、摊铺机,珀金斯2406J-E13TA发动机都能提供强劲动力。以挖掘机为例,它能使铲斗有力地切入坚硬土石,高效完成挖掘任务;装载机装配此发动机后,满载物料时起步、爬坡都能轻松应对,极大提高了物料转运效率,加快工程进度。在农业生产中,珀金斯2406J-E13TA发动机同样发挥着重要作用。拖拉机依靠它牵引重型农具进行深耕、播种等作业,联合收割机在它的驱动下,能快速且精准地完成谷物的收割、脱粒与清选,助力农业丰收。

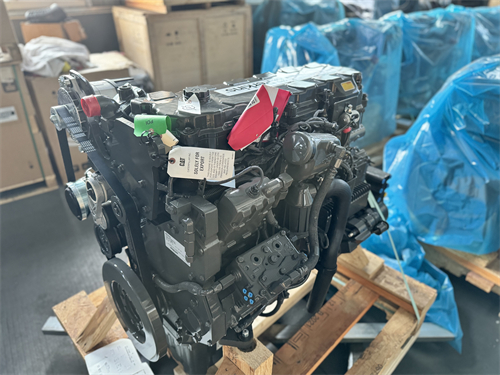

二、2406J-E13TA发动机总成大揭秘

(一)外观与结构

珀金斯2406J-E13TA发动机总成外观设计简洁而硬朗,线条流畅且富有力量感,整体布局紧凑合理,各部件衔接紧密,不仅有效节省了安装空间,还便于维护与检修。其外壳采用高强度合金材质,具备出色的抗冲击和耐腐蚀性能,能够在恶劣的工作环境下为内部精密部件提供可靠保护,延长发动机的使用寿命。

深入到内部结构,这款发动机采用直列六缸的气缸排列方式,这种布局使得发动机的整体结构较为规整,各气缸的工作状态相对独立又协同配合,保证了动力输出的平稳性和连续性。在机体材质方面,选用了高强度的铸铁材料,铸铁具有良好的耐磨性、减震性以及铸造工艺性,能够承受发动机工作时产生的高温、高压和机械应力,确保发动机在长时间、高强度的工作条件下依然稳定可靠。例如在矿山开采中,设备需要长时间不间断作业,2406J-E13TA发动机凭借其坚固的机体材质,能够经受住频繁的启动、停止以及剧烈的震动冲击,始终保持良好的运行状态。

(二)性能参数解读

从性能参数来看,珀金斯2406J-E13TA发动机表现十分出色。它的最大功率可达430kW,在面对大型工程设备如重型起重机、大型盾构机等需要强大动力支持的作业场景时,能够轻松输出强劲动力,确保设备顺利完成各项艰巨任务。扭矩方面,该发动机的最大扭矩高达2634N・m,这意味着它在低速时就能提供强大的牵引力,使机械设备在起步、爬坡、重载运输等工况下都能展现出卓越的性能。以装载机为例,在满载物料爬坡时,强大的扭矩能使装载机轻松克服重力,稳定地攀爬斜坡,提高作业效率。转速方面,其额定转速通常在1800-2200r/min之间,这样的转速范围既保证了发动机在不同工况下都能高效运行,又兼顾了燃油经济性和动力输出的平衡。

与同类产品相比,珀金斯2406J-E13TA发动机在功率和扭矩上具有明显优势。一些同类型号发动机虽然在功率上能达到相近水平,但在扭矩输出上却难以与之媲美。在一些对扭矩要求较高的土方作业中,其他发动机可能会出现动力不足、设备运行卡顿的情况,而2406J-E13TA发动机则能凭借其强大的扭矩,使设备运行更加顺畅,大大提高了作业效率。

三、零配件的“宝藏库”

(一)丰富多样的配件种类

珀金斯2406J-E13TA发动机的零配件种类丰富,涵盖了从关键部件到辅助部件,再到保养件等各个方面,能够全方位满足发动机的维修、保养和升级需求。

关键部件如活塞、活塞销、活塞卡环、活塞环、缸套、缸盖、汽缸垫等,是发动机运行的核心组件。活塞在气缸内做往复运动,将燃料燃烧产生的热能转化为机械能,其质量和性能直接影响发动机的动力输出。活塞环则起到密封、控油和导热的作用,确保气缸内的气体压力稳定,防止机油进入燃烧室,同时将活塞的热量传递给缸套。缸套作为活塞运动的轨道,需要具备良好的耐磨性和密封性,以保证发动机的正常工作。

进气门、排气门、连杆瓦、曲轴瓦、曲轴、连杆、曲轴前后油封、止推片等重要零件,也在保证发动机正常运转中发挥着不可或缺的作用。进气门和排气门负责控制发动机的进气和排气过程,确保混合气的充分进入和废气的及时排出;连杆瓦和曲轴瓦则为连杆和曲轴提供支撑和润滑,减少摩擦和磨损;曲轴是发动机的关键部件之一,它将活塞的往复运动转化为旋转运动,输出动力;连杆则连接活塞和曲轴,传递动力。

辅助部件同样重要,风扇皮带用于驱动风扇,为发动机散热;机油泵负责将机油输送到发动机各个部件,实现润滑和冷却;高压油泵则为燃油喷射提供高压燃油,保证燃油的充分燃烧;水泵用于循环冷却液,维持发动机的正常工作温度。

各类修理包,如上下修包、气门油封等,为发动机的维修提供了便利。涡轮增压器、电子调速器、油压感应器、压力感应器、转速感应器、启动马达、充电机、节温器、油水分离器等电子和机械部件,也在发动机的运行控制、监测和维护中发挥着重要作用。

保养件方面,机油、柴油滤清器、机油滤清器、空气滤清器等对于发动机的日常维护起着关键作用。机油能够润滑发动机内部的各个部件,减少摩擦和磨损;柴油滤清器和机油滤清器可以过滤掉燃油和机油中的杂质,保护发动机内部的精密部件;空气滤清器则能过滤进入发动机的空气,防止灰尘和杂质进入气缸,提高发动机的可靠性和使用寿命。

(二)高品质的配件保障

珀金斯2406J-E13TA发动机的配件以高品质著称,这得益于其优质的材料和严格的制作工艺。关键部件如活塞和缸套通常采用高强度的合金材料,这些材料具有出色的耐高温、高压性能,能够在发动机苛刻的工作环境下保持稳定的性能,确保发动机的动力输出和可靠性。在制作工艺上,经过精密锻造、机械加工、热处理等多道工序,严格控制每个部件的尺寸精度和表面质量,使其达到最佳的配合状态。

机油滤清器、柴油滤清器等保养件,采用高效的过滤材料和先进的制造工艺,能够有效过滤杂质,保护发动机内部的清洁,延长发动机的使用寿命。例如,机油滤清器的滤纸具有高精度的过滤孔径,能够拦截微小的金属颗粒和杂质,同时保证机油的顺畅流通。

电子调速器、油压感应器等电子部件,具有高精度和高稳定性,能够准确控制发动机的运行状态。这些电子部件经过严格的质量检测和校准,确保在各种工况下都能可靠工作,为发动机的稳定运行提供了有力保障。

以一台长期在矿山恶劣环境下作业的装载机为例,其配备的珀金斯2406J-E13TA发动机,由于使用了高品质的配件,在长时间的高强度工作中,依然保持着良好的性能。即使面对频繁的启动、停止以及剧烈的震动冲击,发动机的关键部件如活塞、缸套等磨损极小,各辅助部件和保养件也能正常工作,有效地减少了设备的故障率,提高了作业效率。高品质的配件不仅能够保证发动机的性能和可靠性,还能降低维修成本和停机时间,为用户带来更大的经济效益。

四、购买与保养那些事儿

(一)购买指南

在购买珀金斯2406J-E13TA发动机总成及零配件时,首先务必确认发动机型号和配件名称,这是确保适配的关键。发动机型号决定了配件的规格和参数,不同型号发动机的配件可能在尺寸、性能等方面存在差异。例如,若误将其他型号发动机的活塞安装到2406J-E13TA发动机上,可能会导致发动机无法正常工作,甚至造成严重损坏。准确核对配件名称也同样重要,避免因名称相似但实际功能不同而买错配件。

关注配件的适用性和兼容性也至关重要。即使是同一型号的发动机,也可能因生产年份、排放标准等因素而需要不同的配件。在购买前,要详细了解自己发动机的具体情况,如生产批次、是否进行过改装等,并与供应商沟通确认配件的适用性。可以通过查阅发动机的使用手册、咨询专业技术人员或与珀金斯官方客服联系等方式,获取准确的配件信息。

辨别真假配件也是购买过程中的重要环节。一般来说,正规的珀金斯柴油机配件都会有证件和合格证明,如合格证、检验章、出厂日期等,大的修理厂或正规地方生产的产品更是如此。如果购买时商家拿不出这些证件,很可能是假的或翻新件。珀金斯品牌原厂配件会有制造商的电话、地址和生产日期,包装上也会有原厂标志。假冒产品的标志可能比较粗糙,包装较差,没有生产日期,有的还可以通过防伪标志来验证真假。此外,正品配件的外观通常比较光滑、平整,喷漆均匀,没有明显的色差,而假配件的外观可能比较粗糙,存在明显的瑕疵。还可以关注配件的价格,价格过低的配件很可能是假冒伪劣产品。

为了确保购买到正品配件,应选择正规的购买渠道。珀金斯在全球范围内拥有众多经销商宁波日昕动力科技有限公司,我们能够提供较为准确的产品信息和专业的售后服务。可以通过珀金斯经销代理商官方网站(www.rxdlkj.com)查询经销商宁波日昕动力科技有限公司的名单和联系方式,直接与我们进行沟通和购买。一些知名的线上平台也有销售珀金斯发动机配件,但在选择时要注意核实商家的资质和信誉。同时,要保存好购买凭证,以便在出现质量问题时能够维护自己的权益。

(二)保养秘籍

定期保养是确保珀金斯2406J-E13TA发动机长期稳定运行的关键,它能有效延长发动机的使用寿命,提高其性能和可靠性。

燃油系统的保养至关重要。燃油系统的清洁直接影响发动机的燃烧效率和动力输出。建议每2年或4万公里(以先到者为准)清洗一次燃油系统,可以使用优质的燃油系统清洗剂,有效清除燃烧室、进排气门和燃油管路中的胶质、积碳、沉积物等异物,保持燃油系统各部位的清洁。定期清洁油嘴,用优质的喷油器系统清洗剂清洗喷油器,清除喷油器积碳,消除发动机抖动、迟滞等问题,使油气混合比更准确。同时,要定期检查汽油滤芯是否堵塞,避免因滤芯堵塞导致燃油供应不畅,影响发动机性能。为了避免汽油泵损坏产生异响,需要定期检查油泵,最好前往专业的汽车维修店进行维修。

机油系统的保养同样不可忽视。机油不仅起到润滑作用,减少机件之间的摩擦和磨损,还承担着冷却、清洁、密封和防锈等多重功能。要定期检查机油冷却系统是否正常工作,包括机油散热器、冷却风扇、冷却水管路等部件是否完好、无堵塞、无漏水现象。机油冷却系统是确保机油温度稳定的关键,当这些部件出现故障时,机油无法得到有效的冷却,从而导致温度升高,影响发动机的正常工作。要注意机油泵的工作状态,机油泵是柴油机润滑系统的重要组成部分,负责将机油从油底壳中抽出并输送到各个需要润滑的机件。如果机油泵出现故障,如泵体损坏、泵轴磨损、泵轮脱落等,将导致机油压力下降,机油循环不畅,从而引起机油温度升高,加剧机件的磨损。建议按照发动机使用手册的要求定期更换机油和机油滤清器,以保证机油的清洁和润滑性能。

冷却系统的保养对于发动机的正常运行也起着重要作用。发动机在工作过程中会产生大量的热量,如果不能及时散发出去,会导致发动机温度过高,影响其性能和可靠性。要定期检查水泵、散热器、冷却液等是否正常工作,确保冷却水温度在正常范围内,冷却水管路畅通,散热器清洁。长期使用硬水会使水箱及水道各处形成大量水垢,导致散热不良,因此应尽量使用软水或专用的冷却液。要定期检查冷却液的液位和浓度,及时添加或更换冷却液,以保证冷却系统的正常工作。

正确的保养对发动机寿命有着深远的影响。以一台长期在建筑工地作业的装载机为例,其配备的珀金斯2406J-E13TA发动机,由于严格按照保养要求,定期对燃油系统、机油系统和冷却系统进行保养,在使用多年后,发动机依然保持着良好的性能,动力输出稳定,故障率低。相反,如果忽视保养,发动机可能会出现各种问题,如动力下降、油耗增加、故障频发等,严重缩短发动机的使用寿命,增加维修成本和停机时间。因此,为了让珀金斯2406J-E13TA发动机始终保持最佳状态,一定要重视保养工作,严格按照保养周期和要求进行操作。

五、用户故事与案例分享

为了让大家更直观地感受珀金斯2406J-E13TA发动机的性能与优势,我们来分享一些真实的用户故事。

(一)建筑公司:高效施工的“利器”

某大型建筑公司在城市地标性建筑的建设中,选用了配备珀金斯2406J-E13TA发动机的多台工程机械,包括大型挖掘机、装载机和起重机。在挖掘地基时,挖掘机的作业环境十分复杂,地下土质坚硬且夹杂着大量岩石。但得益于2406J-E13TA发动机强大的动力输出,挖掘机的铲斗能够有力地切入土石,挖掘效率比之前使用的其他设备提高了30%。在物料转运环节,装载机配备的该发动机展现出了强大的扭矩优势,即使满载物料,在工地的斜坡和崎岖道路上也能轻松行驶,运输效率大幅提升。

在项目进行到一半时,一台起重机的发动机出现了故障,经检查是涡轮增压器损坏。建筑公司立即联系了珀金斯的经销商宁波日昕动力科技有限公司,很快就拿到了正品配件并完成了更换。由于更换及时,设备停机时间仅为一天,大大减少了对工程进度的影响。这次经历让建筑公司深刻体会到了珀金斯发动机配件供应的及时性和高效性。

(二)农场主:农业生产的“好帮手”

一位拥有大面积农田的农场主,购买了一台搭载珀金斯2406J-E13TA发动机的大型拖拉机和联合收割机。在春耕时节,拖拉机需要牵引重型犁具进行深耕作业,面对坚硬的土地,2406J-E13TA发动机轻松应对,动力强劲且稳定,能够持续保持较高的作业速度,一天内完成的耕地面积比之前使用的小功率拖拉机增加了50%。

在夏收季节,联合收割机的作业强度极大,需要长时间连续工作。珀金斯发动机凭借其出色的可靠性,在整个收割季中稳定运行,从未出现过故障。不过,在一次收割作业后,农场主发现收割机的机油压力偏低。他按照操作手册的指引,检查了机油滤清器和机油泵,发现机油滤清器堵塞。他及时更换了珀金斯原厂的机油滤清器,问题得到了解决。这次经历让农场主意识到定期保养和使用正品配件的重要性。

六、未来展望与技术趋势

在全球倡导节能减排和智能化发展的大背景下,发动机技术正朝着新能源融合和智能化方向大步迈进,珀金斯2406J-E13TA发动机也不例外。

在新能源融合方面,混合动力技术成为重要发展方向。将传统燃油发动机与电动机相结合,可根据不同工况智能切换动力源,从而有效降低燃油消耗和尾气排放。在一些对排放要求较高的城市建筑施工场景中,当设备处于低速、轻载状态时,可切换至纯电动模式运行,减少污染物排放;而在高速、重载工况下,则依靠燃油发动机提供强劲动力,确保设备正常作业。这种混合动力模式既能充分发挥珀金斯2406J-E13TA发动机动力强劲的优势,又能利用电动驱动的高效、环保特性,提高设备的综合性能。此外,氢能源发动机也在逐步研发探索中,未来若能成功应用于2406J-E13TA发动机平台,将实现真正意义上的零排放,为环保事业做出更大贡献。

智能化也是未来发动机发展的关键趋势。珀金斯2406J-E13TA发动机有望配备更先进的智能控制系统,实现对发动机运行状态的实时监测和精准调控。通过传感器收集发动机的转速、温度、压力、油耗等数据,并利用大数据分析和人工智能技术,对发动机的性能进行优化。当监测到某一零部件出现异常磨损或故障隐患时,系统可及时发出预警,并提供相应的维修建议,实现预防性维护,减少设备停机时间。智能化还体现在发动机与设备其他系统的协同工作上,例如与工程机械的智能操控系统相连,根据作业需求自动调整发动机的输出功率和扭矩,提高设备的作业效率和智能化水平。

在未来,随着技术的不断进步和应用场景的拓展,珀金斯2406J-E13TA发动机有望在更多领域发挥重要作用。在船舶动力领域,其强大的动力和可靠性将使其成为内河运输船舶和小型海洋作业船舶的理想选择;在分布式能源领域,该发动机可作为应急电源或备用电源,为医院、数据中心等重要场所提供稳定的电力保障。凭借不断的技术创新和对市场需求的精准把握,珀金斯2406J-E13TA发动机必将在未来的工业领域中持续绽放光彩。

七、总结与互动

珀金斯2406J-E13TA发动机总成凭借其卓越的性能、紧凑合理的结构设计,在工业领域发挥着重要作用,成为众多机械设备的核心动力。而丰富多样且高品质的零配件,不仅是发动机稳定运行的坚实后盾,更为其维修、保养和升级提供了全方位的支持。在购买和保养过程中,只要掌握正确的方法和要点,就能确保发动机始终保持良好的运行状态,延长使用寿命。

相信大家在使用珀金斯2406J-E13TA发动机或相关配件的过程中,一定积累了不少宝贵的经验,也可能遇到过各种问题。欢迎在评论区留言分享你的故事,无论是成功的案例,还是亟待解决的难题,都可以说出来,大家一起交流探讨。如果你对发动机总成或零配件还有其他疑问,也尽管提问,我会尽力为大家解答。同时,也别忘了关注我的后续内容,我将持续为大家带来更多关于发动机领域的精彩知识和实用信息。

1、 Entering the Perkins 2406J-E13TA engine

In the industrial field, engines can be regarded as the "heart" of mechanical equipment, and their performance directly affects the operational efficiency and stability of the equipment. The Perkins 2406J-E13TA engine, as a highly anticipated product in the industry, has emerged in numerous application scenarios with outstanding performance.

In the field of construction machinery, whether it is busy excavators and loaders on construction sites, or indispensable rollers and pavers in road construction, the Perkins 2406J-E13TA engine can provide strong power. Taking excavators as an example, they can enable the bucket to forcefully cut into hard soil and rocks, efficiently completing excavation tasks; After the loader is equipped with this engine, it can easily handle starting and climbing when fully loaded with materials, greatly improving material transfer efficiency and accelerating project progress. In agricultural production, the Perkins 2406J-E13TA engine also plays an important role. Tractors rely on it to tow heavy agricultural tools for deep plowing, sowing, and other operations. Under its drive, combine harvesters can quickly and accurately complete grain harvesting, threshing, and cleaning, assisting in agricultural harvests.

2、 2406J-E13TA Engine Assembly Unveiled

(1) Appearance and Structure

The exterior design of the Perkins 2406J-E13TA engine assembly is simple yet robust, with smooth and powerful lines. The overall layout is compact and reasonable, with tightly connected components, which not only effectively saves installation space but also facilitates maintenance and repair. Its shell is made of high-strength alloy material, which has excellent impact resistance and corrosion resistance, and can provide reliable protection for internal precision components in harsh working environments, extending the service life of the engine.

Going deep into the internal structure, this engine adopts an inline six cylinder cylinder arrangement, which makes the overall structure of the engine more orderly. The working state of each cylinder is relatively independent and coordinated, ensuring the smoothness and continuity of power output. In terms of body material, high-strength cast iron material is selected. Cast iron has good wear resistance, shock absorption, and casting processability, and can withstand the high temperature, high pressure, and mechanical stress generated during engine operation, ensuring that the engine remains stable and reliable under long-term, high-intensity working conditions. For example, in mining operations, equipment needs to operate continuously for a long time. The 2406J-E13TA engine, with its sturdy body material, can withstand frequent starting, stopping, and severe vibration impacts, and always maintain good operating conditions.

(2) Interpretation of Performance Parameters

In terms of performance parameters, the Perkins 2406J-E13TA engine performs exceptionally well. Its maximum power can reach 430kW, and it can easily output strong power when facing large engineering equipment such as heavy cranes, large shield machines, and other work scenarios that require strong power support, ensuring that the equipment can successfully complete various difficult tasks. In terms of torque, the maximum torque of this engine is as high as 2634N · m, which means it can provide strong traction at low speeds, enabling mechanical equipment to demonstrate excellent performance in starting, climbing, heavy transportation and other working conditions. Taking a loader as an example, when fully loaded with materials and climbing a slope, the strong torque can make the loader easily overcome gravity, climb the slope steadily, and improve work efficiency. In terms of speed, its rated speed is usually between 1800-2200r/min, which ensures that the engine can operate efficiently under different working conditions while balancing fuel economy and power output.

Compared with similar products, the Perkins 2406J-E13TA engine has significant advantages in power and torque. Although some similar models of engines can achieve similar levels of power, they are difficult to match in torque output. In some earthwork operations that require high torque, other engines may experience insufficient power and equipment operation lag. However, the 2406J-E13TA engine, with its powerful torque, can make equipment operation smoother and greatly improve work efficiency.

3、 The 'treasure trove' of spare parts

(1) Rich and diverse types of accessories

The Perkins 2406J-E13TA engine has a wide range of spare parts, covering key components, auxiliary components, maintenance parts, and other aspects, which can fully meet the needs of engine maintenance, upkeep, and upgrades.

Key components such as pistons, piston pins, piston retaining rings, piston rings, cylinder liners, cylinder heads, cylinder liners, etc. are the core components of engine operation. The piston undergoes reciprocating motion within the cylinder, converting the thermal energy generated by fuel combustion into mechanical energy. Its quality and performance directly affect the power output of the engine. The piston ring plays a role in sealing, oil control, and heat conduction, ensuring stable gas pressure in the cylinder, preventing oil from entering the combustion chamber, and transferring heat from the piston to the cylinder liner. As the track of piston movement, cylinder liner needs to have good wear resistance and sealing performance to ensure the normal operation of the engine.

Important components such as intake valves, exhaust valves, connecting rod bushings, crankshaft bushings, crankshafts, connecting rods, crankshaft front and rear oil seals, and thrust plates also play an indispensable role in ensuring the normal operation of the engine. The intake and exhaust valves are responsible for controlling the intake and exhaust processes of the engine, ensuring sufficient intake of the mixture and timely discharge of exhaust gases; The connecting rod bearing and crankshaft bearing provide support and lubrication for the connecting rod and crankshaft, reducing friction and wear; The crankshaft is one of the key components of the engine, which converts the reciprocating motion of the piston into rotational motion and outputs power; The connecting rod connects the piston and crankshaft to transmit power.

Auxiliary components are equally important, and the fan belt is used to drive the fan and dissipate heat from the engine; The oil pump is responsible for delivering engine oil to various components of the engine, achieving lubrication and cooling; The high-pressure fuel pump provides high-pressure fuel for fuel injection, ensuring full combustion of the fuel; The water pump is used to circulate coolant and maintain the normal operating temperature of the engine.

Various repair kits, such as upper and lower repair kits, valve oil seals, etc., provide convenience for engine maintenance. Turbocharger, electronic governor, oil pressure sensor, pressure sensor, speed sensor, starter motor, charger, thermostat, oil-water separator and other electronic and mechanical components also play important roles in the operation control, monitoring and maintenance of the engine.

In terms of maintenance parts, engine oil, diesel filters, oil filters, air filters, etc. play a key role in the daily maintenance of the engine. Engine oil can lubricate various components inside the engine, reducing friction and wear; Diesel filters and oil filters can filter out impurities in fuel and oil, protecting the precision components inside the engine; The air filter can filter the air entering the engine, prevent dust and impurities from entering the cylinder, and improve the reliability and service life of the engine.

(2) High quality accessory guarantee

The accessories of the Perkins 2406J-E13TA engine are known for their high quality, thanks to their high-quality materials and strict manufacturing processes. Key components such as pistons and cylinder liners are usually made of high-strength alloy materials, which have excellent high temperature and high pressure resistance and can maintain stable performance in the harsh working environment of the engine, ensuring the power output and reliability of the engine. In terms of production technology, through multiple processes such as precision forging, mechanical processing, and heat treatment, the dimensional accuracy and surface quality of each component are strictly controlled to achieve the best fit state.

Maintenance parts such as oil filters and diesel filters use efficient filtering materials and advanced manufacturing processes to effectively filter impurities, protect the cleanliness of the engine interior, and extend the service life of the engine. For example, the filter paper of an oil filter has a high-precision filtering aperture, which can intercept small metal particles and impurities while ensuring smooth flow of oil.

Electronic components such as electronic speed controllers and oil pressure sensors have high precision and stability, and can accurately control the operating status of the engine. These electronic components undergo strict quality testing and calibration to ensure reliable operation under various working conditions, providing strong support for the stable operation of the engine.

Taking a loader that has been operating in harsh mining environments for a long time as an example, its equipped Perkins 2406J-E13TA engine, due to the use of high-quality components, still maintains good performance during long-term high-intensity work. Even in the face of frequent starting, stopping, and severe vibration impacts, key components of the engine such as pistons and cylinder liners wear very little, and auxiliary and maintenance parts can still work normally, effectively reducing equipment failure rates and improving operational efficiency. High quality accessories not only ensure the performance and reliability of the engine, but also reduce maintenance costs and downtime, bringing greater economic benefits to users.

4、 What are the things to purchase and maintain

(1) Purchase Guide

When purchasing the Perkins 2406J-E13TA engine assembly and spare parts, it is essential to first confirm the engine model and part name, as this is the key to ensuring compatibility. The engine model determines the specifications and parameters of the accessories, and the accessories of different engine models may have differences in size, performance, and other aspects. For example, if the pistons of other engine models are mistakenly installed on the 2406J-E13TA engine, it may cause the engine to malfunction and even result in serious damage. Accurately checking the names of accessories is equally important to avoid buying the wrong accessories due to similar names but different actual functions.

It is also crucial to pay attention to the applicability and compatibility of accessories. Even engines of the same model may require different accessories due to factors such as production year and emission standards. Before purchasing, it is necessary to thoroughly understand the specific situation of your engine, such as production batch, whether it has been modified, etc., and communicate with the supplier to confirm the applicability of the accessories. Accurate accessory information can be obtained by consulting the engine manual, consulting professional technicians, or contacting Perkins' official customer service.

Distinguishing between genuine and fake accessories is also an important step in the purchasing process. Generally speaking, legitimate Perkins diesel engine accessories come with certificates and qualification certificates, such as certificates of conformity, inspection stamps, and production dates. This is especially true for products produced in large repair shops or legitimate places. If the merchant cannot provide these documents when purchasing, they are likely to be fake or refurbished. Perkins brand original accessories will have the manufacturer's phone number, address, and production date, and the packaging will also have the original factory logo. Counterfeit products may have rough markings, poor packaging, no production date, and some can be verified for authenticity through anti-counterfeiting marks. In addition, the appearance of genuine accessories is usually smooth and even, with even painting and no obvious color difference, while the appearance of fake accessories may be rough and have obvious defects. You can also pay attention to the prices of accessories, as accessories with low prices are likely to be counterfeit and inferior products.

To ensure the purchase of genuine accessories, one should choose a legitimate purchasing channel. Perkins has numerous distributors worldwide, including Ningbo Rixin Power Technology Co., Ltd. We are able to provide accurate product information and professional after-sales service. You can check the list and contact information of the distributor Ningbo Rixin Power Technology Co., Ltd. through the official website of Perkins distribution agents (www.rxdlkj. com), and directly communicate and purchase with us. Some well-known online platforms also sell Perkins engine parts, but when choosing, it is important to verify the qualifications and reputation of the merchant. At the same time, it is necessary to keep the purchase voucher well so that one can protect their rights in case of quality issues.

(2) Maintenance Tips

Regular maintenance is the key to ensuring the long-term stable operation of the Perkins 2406J-E13TA engine, which can effectively extend the engine's service life, improve its performance and reliability.

The maintenance of the fuel system is crucial. The cleanliness of the fuel system directly affects the combustion efficiency and power output of the engine. It is recommended to clean the fuel system every 2 years or 40000 kilometers (whichever comes first). High quality fuel system cleaning agents can be used to effectively remove foreign substances such as gum, carbon deposits, and sediments in the combustion chamber, intake and exhaust valves, and fuel pipelines, keeping all parts of the fuel system clean. Regularly clean the fuel nozzle, use high-quality fuel injector system cleaning agent to clean the fuel injector, remove carbon deposits from the fuel injector, eliminate engine shaking, hysteresis and other problems, and make the fuel air mixture more accurate. At the same time, it is necessary to regularly check whether the gasoline filter is clogged to avoid poor fuel supply caused by clogged filter, which may affect engine performance. To avoid abnormal noise caused by damage to the gasoline pump, it is necessary to regularly check the pump and it is best to go to a professional car repair shop for maintenance.

The maintenance of the oil system cannot be ignored either. Engine oil not only provides lubrication, reduces friction and wear between components, but also serves multiple functions such as cooling, cleaning, sealing, and rust prevention. Regularly check whether the oil cooling system is working properly, including whether the oil radiator, cooling fan, cooling water pipeline and other components are intact, unobstructed and leak free. The oil cooling system is the key to ensuring stable oil temperature. When these components fail, the oil cannot be effectively cooled, resulting in an increase in temperature and affecting the normal operation of the engine. Pay attention to the working condition of the oil pump, which is an important component of the diesel engine lubrication system. It is responsible for extracting oil from the oil pan and delivering it to various parts that require lubrication. If there is a malfunction in the oil pump, such as damage to the pump body, wear on the pump shaft, or detachment of the pump wheel, it will cause a decrease in oil pressure and poor oil circulation, resulting in an increase in oil temperature and exacerbating the wear of the components. It is recommended to regularly replace the engine oil and oil filter according to the requirements of the engine manual to ensure the cleanliness and lubrication performance of the oil.

The maintenance of the cooling system also plays an important role in the normal operation of the engine. The engine generates a large amount of heat during operation, and if it cannot be dissipated in a timely manner, it can cause the engine temperature to become too high, affecting its performance and reliability. Regularly check whether the water pump, radiator, coolant, etc. are working properly to ensure that the cooling water temperature is within the normal range, the cooling water pipeline is unobstructed, and the radiator is clean. Long term use of hard water can cause a large amount of scale to form in various parts of the water tank and waterway, leading to poor heat dissipation. Therefore, soft water or specialized coolant should be used as much as possible. Regularly check the coolant level and concentration, and add or replace the coolant in a timely manner to ensure the normal operation of the cooling system.

Proper maintenance has a profound impact on the lifespan of an engine. Taking a loader that has been operating on a construction site for a long time as an example, its equipped Perkins 2406J-E13TA engine, due to strict maintenance requirements, regularly maintains the fuel system, oil system, and cooling system. After years of use, the engine still maintains good performance, stable power output, and low failure rate. On the contrary, if maintenance is neglected, the engine may experience various problems such as decreased power, increased fuel consumption, frequent malfunctions, etc., seriously shortening the service life of the engine, increasing maintenance costs and downtime. Therefore, in order to maintain the best condition of the Perkins 2406J-E13TA engine, it is necessary to pay attention to maintenance work and strictly follow the maintenance cycle and requirements for operation.

5、 User stories and case studies sharing

In order to provide a more intuitive experience of the performance and advantages of the Perkins 2406J-E13TA engine, we will share some real user stories.

(1) Construction Company: A Powerful Tool for Efficient Construction

A large construction company selected multiple construction machinery equipped with Perkins 2406J-E13TA engines, including large excavators, loaders, and cranes, for the construction of landmark buildings in the city. When excavating the foundation, the working environment of the excavator is very complex, with hard underground soil mixed with a large amount of rocks. But thanks to the powerful power output of the 2406J-E13TA engine, the excavator's bucket can effectively cut into soil and rock, increasing excavation efficiency by 30% compared to other equipment previously used. In the material transfer process, the loader is equipped with an engine that demonstrates strong torque advantages. Even when fully loaded with materials, it can easily travel on slopes and rugged roads on construction sites, greatly improving transportation efficiency.

Halfway through the project, the engine of a crane malfunctioned, and upon inspection, it was found that the turbocharger was damaged. The construction company immediately contacted Perkins' distributor, Ningbo Rixin Power Technology Co., Ltd., and soon received the genuine parts and completed the replacement. Due to timely replacement, the equipment downtime is only one day, greatly reducing the impact on the project schedule. This experience has deeply impressed the construction company with the timeliness and efficiency of Perkins engine parts supply.

(2) Farmer: A Good Helper in Agricultural Production

A farmer with a large area of farmland purchased a large tractor and combine harvester equipped with a Perkins 2406J-E13TA engine. During the spring plowing season, tractors need to tow heavy plows for deep plowing operations. Faced with hard soil, the 2406J-E13TA engine can easily handle it, with strong and stable power, able to maintain a high operating speed continuously. The cultivated land area completed in one day has increased by 50% compared to the low-power tractors previously used.

During the summer harvest season, the workload of combine harvesters is extremely high, requiring long periods of continuous operation. The Perkins engine, with its excellent reliability, runs steadily throughout the entire harvest season without any malfunctions. However, after a harvesting operation, the farmer found that the oil pressure of the harvester was low. He followed the instructions in the operation manual to check the oil filter and oil pump, and found that the oil filter was clogged. He promptly replaced the original Perkins oil filter and the problem was resolved. This experience made the farm realize the importance of regular maintenance and using genuine accessories.

6、 Future prospects and technological trends

Against the backdrop of global advocacy for energy conservation, emission reduction, and intelligent development, engine technology is making great strides towards the integration of new energy and intelligence, and the Perkins 2406J-E13TA engine is no exception.

In terms of new energy integration, hybrid technology has become an important development direction. By combining traditional fuel engines with electric motors, the power source can be intelligently switched according to different operating conditions, effectively reducing fuel consumption and exhaust emissions. In some urban construction scenarios with high emission requirements, when the equipment is in a low-speed, light load state, it can switch to pure electric mode operation to reduce pollutant emissions; Under high-speed and heavy load conditions, the equipment relies on a fuel engine to provide strong power and ensure normal operation. This hybrid mode can fully leverage the powerful advantages of the Perkins 2406J-E13TA engine, while also utilizing the efficient and environmentally friendly features of electric drive to improve the overall performance of the equipment. In addition, hydrogen energy engines are gradually being developed and explored. If successfully applied to the 2406J-E13TA engine platform in the future, it will achieve true zero emissions and make greater contributions to environmental protection.

Intelligence is also a key trend in the future development of engines. The Perkins 2406J-E13TA engine is expected to be equipped with a more advanced intelligent control system, enabling real-time monitoring and precise control of the engine's operating status. Collect engine speed, temperature, pressure, fuel consumption and other data through sensors, and optimize engine performance using big data analysis and artificial intelligence technology. When abnormal wear or potential faults are detected in a certain component, the system can issue a warning in a timely manner and provide corresponding maintenance suggestions to achieve preventive maintenance and reduce equipment downtime. Intelligence is also reflected in the collaborative work between the engine and other systems of the equipment, such as connecting with the intelligent control system of construction machinery, automatically adjusting the output power and torque of the engine according to operational requirements, and improving the operational efficiency and intelligence level of the equipment.

In the future, with the continuous advancement of technology and the expansion of application scenarios, the Perkins 2406J-E13TA engine is expected to play an important role in more fields. In the field of ship propulsion, its powerful power and reliability will make it an ideal choice for inland transport vessels and small ocean operation vessels; In the field of distributed energy, this engine can serve as an emergency or backup power source, providing stable power supply for important places such as hospitals and data centers. With continuous technological innovation and precise grasp of market demand, the Perkins 2406J-E13TA engine will continue to shine in the future industrial field.

7、 Summary and Interaction

The Perkins 2406J-E13TA engine assembly plays an important role in the industrial field with its excellent performance and compact and reasonable structural design, becoming the core power of many mechanical equipment. And the rich, diverse, and high-quality spare parts are not only a solid support for the stable operation of the engine, but also provide comprehensive support for its maintenance, upkeep, and upgrades. By mastering the correct methods and key points during the purchase and maintenance process, it is possible to ensure that the engine always maintains a good operating condition and extends its service life.

I believe that everyone has accumulated valuable experience and may have encountered various problems while using the Perkins 2406J-E13TA engine or related accessories. Welcome to leave a comment in the comment section to share your story. Whether it's a successful case or an urgent problem that needs to be solved, you can speak up and discuss together. If you have any other questions about the engine assembly or spare parts, feel free to ask and I will do my best to answer them for everyone. At the same time, don't forget to follow my follow-up content. I will continue to bring you more exciting knowledge and practical information about the engine field.

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska