Cat Parts 3126b 3176c 3196 3406e Blower Motor 2688792 268-8792 Fits for D10 D11

Cat Parts Blower Motor Unveiled

In the world of construction machinery, every component is like a key gear in precision instruments, small but crucial. Today, let's delve into the Cat parts 3126b, 3176c, 3196, 3406e blower motors 2688792, 268-8792 suitable for D10 and D11. For many non professionals, these model numbers may seem like a mysterious code, but for friends in related industries, they are the key to ensuring the normal operation of equipment. Whether in dusty construction sites or resource extraction mines, the busy figures of D10 and D11 equipment can be seen everywhere, and these blower motors, like their "respiratory system", silently play an indispensable role.

The uniqueness of these blower motors

3126b blower motor: The 3126b blower motor is known for its excellent stability. It adopts advanced high-temperature resistant materials, which can operate continuously and stably under common high-temperature conditions of construction machinery, effectively avoiding performance degradation caused by high temperature. In some large-scale projects with continuous operation, its stability advantage is highlighted, ensuring that the equipment ventilation and heat dissipation system is always in the best condition. Moreover, its unique blade design ensures uniform and efficient air flow, providing just the right amount of cooling air for key components such as engines, ensuring the normal operation of equipment in various complex environments.

3176c blower motor: One of the highlights of 3176c is its high efficiency and energy-saving characteristics. By utilizing new electromagnetic technology, energy loss is significantly reduced in the process of converting electrical energy into mechanical energy, which not only saves energy consumption costs for equipment, but also responds to the current trend of energy conservation and environmental protection. Compared with motors of the same type, it can consume less electricity while providing the same air volume. In industries with high electricity consumption such as mining, the use of 3176c motors can significantly reduce operating costs. In addition, its maintenance convenience is also worth mentioning. The modular design makes it easier for maintenance personnel to perform daily maintenance or troubleshooting, reducing downtime and improving equipment efficiency.

3196 blower motor: The 3196 blower motor pursues ultimate performance and has ultra-high wind pressure output capability. This means it can overcome greater resistance and transport air to farther and more complex pipeline systems. In some large construction sites with strict ventilation requirements, it can easily handle long-distance and multi curved ventilation duct layouts, ensuring that each construction area can receive sufficient fresh air. Its sturdy and durable shell design can effectively resist external impacts and harsh environmental erosion, whether it is a desert construction site with sandstorms or a damp and rainy coastal construction project, it can operate reliably.

3406e blower motor: 3406e focuses on intelligent control. Equipped with advanced sensors and intelligent control systems, it can automatically adjust the air volume based on the real-time operating status of the equipment. For example, when the engine load increases and the temperature rises, it will quickly increase the air volume to enhance the heat dissipation effect; When the device is operating at low load, it will automatically reduce the air volume to save energy. This intelligent adaptive adjustment function not only improves the safety and stability of device operation, but also further optimizes energy utilization efficiency, bringing users a more convenient and efficient user experience.

Detailed explanation of models 2688792 and 268-8792

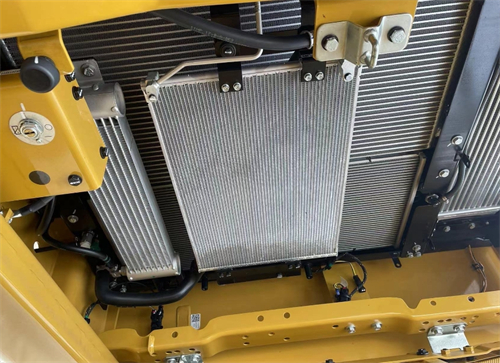

Let's talk about the specific models 2688792 and 268-8792. From the perspective of adapting D10 and D11 devices, their rated voltage is generally 24V, which matches the electrical system voltage of D10 and D11 to ensure stable operation. The rated power is around [X] watts, which can provide sufficient power to drive the fan blades to rotate and achieve efficient ventilation. In terms of working principle, they utilize the principle of electromagnetic induction. When current passes through the motor winding, a rotating magnetic field is generated, which drives the rotor to rotate. This is consistent with common motor principles, but in terms of specific winding design and magnetic circuit optimization, they are more suitable for the working environment of D10 and D11.

Compared to other models, 2688792 and 268-8792 are more compact in size, making them easier to install and layout within the limited equipment space of D10 and D11. In terms of heat dissipation performance, they have been specially designed with efficient heat dissipation fins and thermal conductive materials, which can quickly dissipate the heat generated by motor operation, avoiding faults caused by overheating and greatly improving reliability under long-term high load operation.

Practical application case sharing

In mining operations, D10 bulldozers are responsible for heavy material transportation tasks. Due to the harsh mining environment and prolonged high load operation of equipment engines, heat dissipation issues have become a key factor affecting the normal operation of the equipment. After installing the 3126b blower motor, its stable performance ensures that the engine is always within the appropriate operating temperature range. The number of equipment shutdowns caused by poor heat dissipation has significantly decreased, and the monthly downtime due to engine overheating has been reduced from [X] hours to within [X] hours, greatly improving the efficiency of mining operations and reducing economic losses caused by equipment failures.

At the construction site of large-scale building projects, D11 grader is responsible for site leveling work. The construction environment here is complex, with long and winding ventilation ducts. The 3196 blower motor, with its powerful wind pressure output capability, successfully delivers fresh air to various construction areas. Construction workers have reported that in the past, in some ventilation blind spots, the air was turbid and uncomfortable during work. However, after using the 3196 motor, the air quality of the entire construction site has significantly improved, greatly enhancing work comfort and reducing health hazards caused by air quality issues, ensuring the smooth progress of construction.

How to choose and maintain

When you are ready to choose Cat parts 3126b, 3176c, 3196, 3406e blower motors 2688792, 268-8792 suitable for D10 and D11, the first step is to clarify the actual operating requirements of the equipment. For example, if the equipment frequently operates in high-temperature environments for long periods of time, such as in the mining scene mentioned earlier, the high temperature resistance characteristics of 3126b are more suitable; If you are sensitive to energy consumption costs, the energy-saving advantages of 3176c are worth considering. At the same time, it is necessary to check whether the motor meets relevant industry standards, check the product's certification certificate, and ensure its reliable quality.

In terms of maintenance, regular cleaning is essential. During the operation of the motor, impurities such as dust and oil stains may be adsorbed, especially in harsh engineering environments, which may affect the motor's heat dissipation and normal operation. Compressed air or specialized cleaning tools can be used to regularly clean the dust on the surface and inside of the motor. Regularly check whether the wiring of the motor is loose, ensure stable electrical connections, and avoid motor failures caused by poor contact. Regularly lubricating the bearings of the motor, selecting appropriate lubricating oil, and adding it according to the prescribed dosage can effectively extend the service life of the bearings and ensure the smooth operation of the motor.

Summary and Prospect

Cat parts 3126b, 3176c, 3196, 3406e blower motors 2688792, 268-8792 play a critical role in the ventilation and heat dissipation systems of D10 and D11 equipment due to their unique performance advantages. From the stable and reliable 3126b, to the energy-saving and efficient 3176c, to the strong wind pressure 3196, and the intelligent regulation 3406e, each has its irreplaceable value. In practical applications, they effectively solve the ventilation and heat dissipation problems of equipment under different working conditions, improving the operational efficiency and reliability of the equipment.

Looking ahead to the future, with the continuous development of the construction machinery industry, the requirements for equipment performance and environmental protection will also become increasingly high. These blower motors will also develop towards higher efficiency, energy conservation, intelligence, and adaptability to more complex and harsh environments. Perhaps in the near future, we will see new blower motors that integrate more advanced technologies, bringing superior performance to devices such as D10 and D11, and helping the construction machinery industry reach new heights of development. Whether on construction sites for infrastructure or in various fields of resource development, they will continue to write their own 'industrial legends'.

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska