详细描述

项目 零配件号码 最新件号 描述

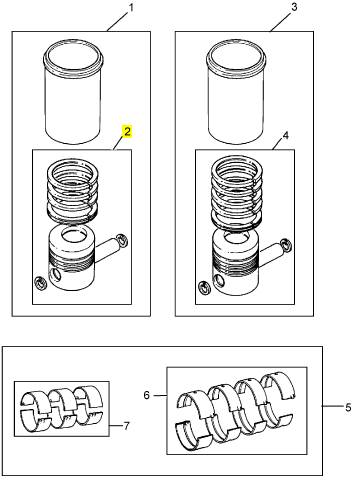

2 U5PR0002 1 检查历史 活塞及圈总成

|

Disassembly and Assembly Section |

|

i02754786 |

|

Engine Oil Pump - Remove |

|

Removal Procedure |

|

NOTICE |

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

|

g01385694 |

|

Illustration 66 |

|

Dispose of all fluids according to local regulations and mandates. |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

1. Drain the coolant from the cooling system into a suitable container for storage or for disposal. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

g01385651 |

|

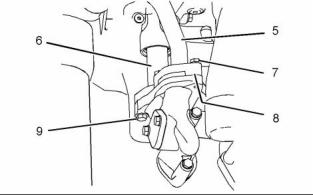

Illustration 67 |

|

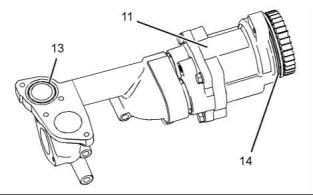

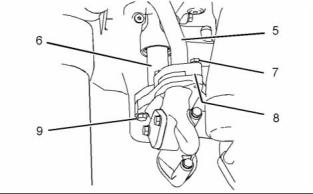

4. Remove bolts (7) and disconnect tube assembly (5) from engine oil pump (11). Remove O-ring seal (8) (not shown) from tube assembly (5). |

|

5. Remove bolts (9) and disconnect tube assembly (6) from engine oil pump (11). |

|

6. Remove bolts (10). |

|

7. Remove bolts (12). |

|

8. Remove engine oil pump (11). |

|

g01385650 |

|

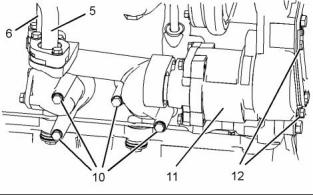

Illustration 65 |

|

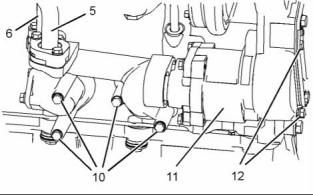

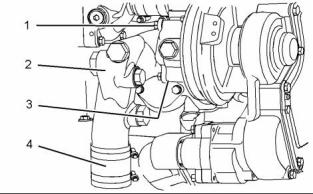

2. Loosen the hose clamps and disconnect hose (4) from connection (2). |

|

3. Remove bolts (1). Remove connection (2) from the water pump. Remove O-ring seal (3) (not shown) from the water pump. |

|

g01386064 |

|

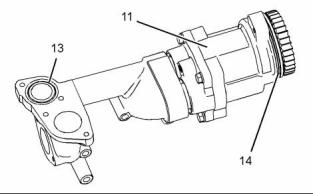

Illustration 68 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

33 Disassembly and Assembly Section |

|

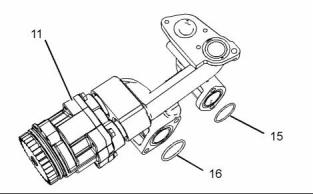

9. Remove O-ring seals (13) and (14) from engine oil pump (11). |

|

g01391548 |

|

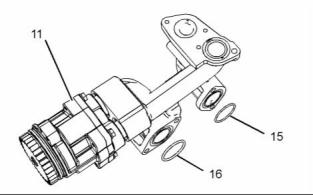

Illustration 69 |

|

10. Remove O-ring seals (15) and (16) from engine oil pump (11). |

|

g01395753 |

|

Illustration 70 |

|

i02754790 |

|

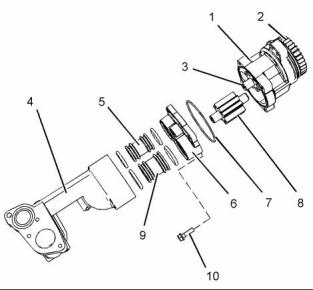

1. Remove manifold (4). |

|

Engine Oil Pump - Disassemble |

|

2. Remove tube assemblies (5) and (9). |

|

3. Remove the O-ring seals from tube assemblies |

|

(5) and (9). |

|

Disassembly Procedure |

|

4. Use Tooling (A) in order to remove gear (2). 5. Remove bolts (10). |

|

Table 15 |

|

Required Tools Part |

|

6. Remove cover (6) from engine oil pump (1). |

|

Tool |

|

Number |

|

Part Description |

|

Qty |

|

A |

|

- |

|

Puller |

|

1 |

|

7. Remove shaft assembly (3) and shaft assembly |

|

(8) from engine oil pump (1). |

|

Start By: |

|

8. Remove oil seal (7). |

|

a. Remove the engine oil pump. Refer to |

|

Disassembly and Assembly, “Engine Oil Pump - Remove”. |

|

i02754791 |

|

Engine Oil Pump - Assemble |

|

Assembly Procedure |

|

Table 16 |

|

Required Tools |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

POWERPART Rubber Grease |

|

A |

|

21820221 |

|

1 |

|

1. Ensure that all components of the engine oil pump are clean and free from wear or damage. Refer to the Specifications, “Engine Oil Pump” for more information. |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

|

34 |

|

KENR6906 |

|

Disassembly and Assembly Section |

|

8. Install new O-ring seals to tube assemblies (5) and (9). Lubricate the O-ring seals with Tooling (A). |

|

9. Install tube assemblies (5) and (9) to cover (6). |

|

10. Install manifold (4) onto tube assemblies (5) and (9). |

|

End By: |

|

a. Install the engine oil pump. Refer to Disassembly and Assembly, “Engine Oil Pump - Install”. |

|

i02754792 |

|

Engine Oil Pump - Install |

|

Installation Procedure |

|

g01395753 |

|

Illustration 71 |

|

Table 17 |

|

Required Tools |

|

Tool |

|

Part Number |

|

Part Description |

|

Qty |

|

POWERPART Rubber Grease |

|

A |

|

218200221 |

|

1 |

|

NOTICE Keep all parts clean from contaminants. |

|

Contaminants may cause rapid wear and shortened component life. |

|

g01146945 |

|

Illustration 72 |

|

2. Lubricate shaft assemblies (3) and (8) with clean engine oil. Install the shaft assemblies into engine oil pump (1). |

|

3. Install a new oil seal (7) to engine oil pump (1). |

|

4. Position cover (6) onto engine oil pump (1) and install bolts (10). |

|

5. Tighten bolts (10) to a torque of 28 N·m (21 lb ft). |

|

g01391548 |

|

Illustration 73 |

|

Always wear protective gloves when handling parts that have been heated. |

|

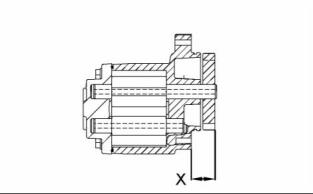

6. Heat gear (2) to a temperature of 316 °C (600 °F). |

|

7. Install gear (2) to shaft assembly (3). Ensure that Dimension (X) is 29.40 ± 0.50 mm (1.158 ± 0.020 inch). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

KENR6906 |

|

35 Disassembly and Assembly Section |

|

6. Install new O-ring seal (8) (not shown) to tube assembly (5). Connect the tube assembly to engine oil pump (11) and install bolts (7). |

|

7. Tighten bolts (7) and bolt (9) to a torque of 28 N·m (21 lb ft). |

|

g01386064 |

|

Illustration 74 |

|

1. Install new O-ring seal (14) to engine oil pump (11). Lubricate the O-ring seal with Tooling (A). |

|

2. Install new O-ring seals (13), (15) and (16) to |

|

engine oil pump (11). |

|

g01385650 |

|

Illustration 77 |

|

8. Install a new O-ring seal (3) (not shown) to the water pump. position connection (2) and install bolts (1). Tighten the bolts to a torque of 28 N·m (21 lb ft). |

|

9. Connect hose (4) to connection (2). Tighten the hose clamps securely. |

|

10. Fill the cooling system. Refer to Operation and Maintenance Manual, “Cooling System Coolant - Change”. |

|

i02754793 |

|

g01385651 |

|

Illustration 75 |

|

Water Pump - Remove |

|

Removal Procedure |

|

Start By: |

|

a. Remove the front plate and the support bracket. Refer to Disassembly and Assembly, “Front Plate - Remove” |

|

NOTICE Keep all parts clean from contaminants. |

|

g01385694 |

|

Illustration 76 |

|

Contaminants may cause rapid wear and shortened component life. |

|

3. Position engine oil pump (11) and install bolts (12) finger tight. |

|

4. Install bolts (10). Tighten bolts (10) and (12) to a torque of 28 N·m (21 lb ft). |

|

5. Connect tube assembly (6) to engine oil pump (11) and install bolts (9). |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska