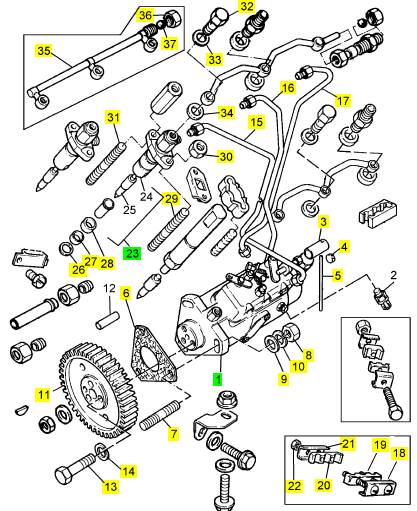

详细描述

项目 零配件号码 最新件号 描述

1 2643 B134 1 2643 B134 燃料喷射泵

3 3281 M002 1 3281 M002 套筒

4 31718104 1 31718104 密封

5 31718105 1 31718105 金属线

6 33828112 1 3682 A008 密合垫 - 燃料的 INJ 泵

7 2217575 3 2217575 图钉

8 0576002 3 0576002 螺帽

9 0920003 3 0920003 垫圈

10 0920053 3 0920053 垫圈

11 41115379 1 41115379 喷射泵传动机构

11 0350010 1 0350010 合钉

11 1 燃料喷射泵传动机构

13 0746214 3 0746214 螺旋

14 0920053 3 0920053 垫圈

15 3521 E018 1 3521 E018 燃料喷射管 号码1 CYL。

16 3521 E019 1 3521 E019 燃料喷射管 号码2 CYL。

17 3521 E021 1 3521 E021 燃料喷射管 号码3 CYL。

18 38631117 1 38631117 板

19 36845115 1 36845115 夹

20 36845115 1 36845115 夹

21 36511127 1 36511127 板

22 2211401 2 2211401 螺帽

23 2645630 3 2645630 喷油器

(23) 2645630 R 3 2645630 R 喷油器 -交换

26 0921173 3 0921173 喷油器垫圈

27 33813127 3 3311 A041 密封 -喷油器

28 33813126 3 33813126 间隔器

29 2216105 3 2216105 图钉

30 0576002 6 0576002 螺帽

31 2216105 3 2216105 图钉

32 3218 R039 3 3218 R039 班卓琴螺拴

32 0095315 3 0095315 班卓琴螺拴 U186029K

33 2411 D007 3 2411 D007 垫圈

33 0921176 3 0921176 垫圈 U186029K

34 2411 D007 3 2411 D007 垫圈

34 0921176 3 0921176 垫圈 U186029K

35 35587359 1 35587359 回油管

36 0576111 1 0576111 螺帽

37 0020006 1 0020006 球

4. Tighten the nut on Tooling (A) until electronic unit injector sleeve (1) is pulled free from the cylinder head. |

g01043165 |

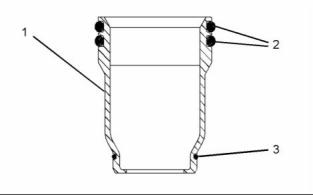

Illustration 17 |

g01393881 |

Illustration 16 |

5. Remove O-ring seals (2) and O-ring seal (3) from electronic unit injector sleeve (1). |

i02754766 Electronic Unit Injector Sleeve - Install |

Installation Procedure |

Table 5 |

Required Tools |

Tool |

Part Number GE50021 GE50023 GE50024 GE50022 CV60893 |

Part Description Injector Sleeve Tool Tapered Brush |

Qty 1 |

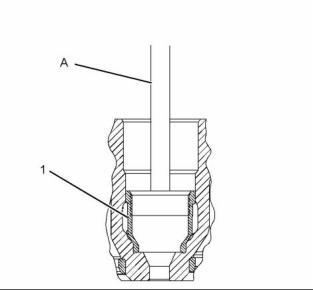

g01393891 |

Illustration 18 |

A |

1 |

2. Install new O-ring seals (2) and (3) to electronic unit injector sleeve (1). |

B C |

Small Bore Brush End Brush |

1 |

1 |

3. Install electronic unit injector sleeve (1) to Tooling (A). |

Retaining Compound |

1 |

4. Apply a small continuous bead of Tooling (C) to |

NOTICE |

surface (X) of electronic unit injector sleeve (1). |

Keep all parts clean from contaminants. |

5. Lubricate O-ring seals (2) with clean engine oil. |

Contaminants may cause rapid wear and shortened component life. |

6. Position electronic unit injector sleeve (1) and Tooling (A) in the cylinder head. Use care not to damage O-ring seals (2) and (3). |

1. Use Tooling (B) to clean the bore in the cylinder |

head for the electronic unit injector sleeve. |

7. Use Tooling (A) and a soft faced hammer to install electronic unit injector sleeve (1) to the cylinder head. |

NOTICE |

Ensure that the electronic unit injector sleeve and the cylinder head bore are completely free of oil, dirt, and sealant debris. |

Note: Ensure that the electronic unit injector sleeve is properly seated in the cylinder head. |

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

KENR6906 |

13 Disassembly and Assembly Section |

8. Install the electronic unit injectors. Refer to Disassembly and Assembly, “Electronic Unit Injector - Install”. |

Installation Procedure |

9. Fill the cooling system with coolant. Refer to Operation and Maintenance, “Cooling System Coolant - Change”. |

i02754770 |

Air Cleaner - Remove and Install |

g01380888 |

Removal Procedure |

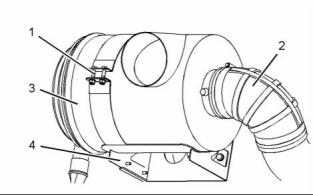

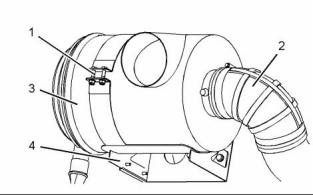

Illustration 20 |

Typical example |

NOTICE Keep all parts clean from contaminants. |

1. If necessary, position mounting bracket (4) on the cylinder head and install the bolts that secure the mounting bracket. Tighten theM12 bolts to a torque of 100 N·m (74 lb ft). Tighten the 3/8" bolts to a torque of 47 N·m (35 lb ft). |

Contaminants may cause rapid wear and shortened component life. |

2. Position air cleaner (3) on mounting bracket (4). Ensure the correct orientation of the air cleaner. |

3. Install fasteners (1). Tighten the fasteners to a torque of 55 N·m (41 lb ft). |

4. Connect hose (2) and tighten the hose clamp securely. |

i02754771 |

Turbocharger - Remove |

g01380888 |

Illustration 19 |

Typical example |

Removal Procedure |

1. Loosen the hose clamp and disconnect hose (2). |

Start By: |

2. Remove fasteners (1) and remove air cleaner (3) from mounting bracket (4). Note the orientation of the air cleaner. |

a. Remove the exhaust elbow. Refer to Disassembly and Assembly, “Exhaust Elbow - Remove and Install”. |

3. If necessary, remove the bolts that secure mounting bracket (4) and remove the mounting bracket. |

NOTICE |

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, test- ing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before open- ing any compartment or disassembling any compo- nent containing fluids. |

Dispose of all fluids according to local regulations and mandates. |

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

14 |

KENR6906 |

Disassembly and Assembly Section |

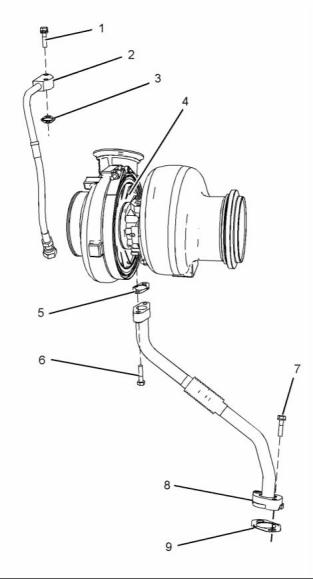

c. Remove tube assembly (2) and joint (3) from |

turbocharger (4). |

NOTICE |

Keep all parts clean from contaminants. |

3. Follow Steps 3 through 3.c in order to remove the |

tube assembly for the oil drain to the turbocharger. |

Contaminants may cause rapid wear and shortened component life. |

a. Remove bolts (6) and (7). b. Remove tube assembly (8). c. Remove joints (5) and (9). |

1. Disconnect the air hoses from the turbocharger inlet and from the turbocharger outlet. |

4. Attach a suitable lifting device to turbocharger (4). The weight of the turbocharger is approximately 32 kg (71 lb). |

g01382805 |

Illustration 22 |

Typical example |

5. Remove nuts (10). Use the lifting device to remove turbocharger (4) from the exhaust manifold. |

6. Remove gasket (11). |

i02754772 |

Turbocharger - Install |

g01380889 |

Illustration 21 |

Installation Procedure |

Typical example |

Table 6 |

2. Follow Steps 2.a through 2.c in order to remove the |

Required Tools Part |

tube assembly for the oil feed to the turbocharger. |

a. Disconnect tube assembly (2) from the engine oil filter base. |

Tool |

Number |

Part Description |

Qty |

A |

CV60889 |

Anti-Seize Compound |

1 |

b. Remove bolts (1). |

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

KENR6906 |

15 Disassembly and Assembly Section |

NOTICE Keep all parts clean from contaminants. |

Contaminants may cause rapid wear and shortened component life. |

1. Ensure that all mating surfaces are clean and free from damage. |

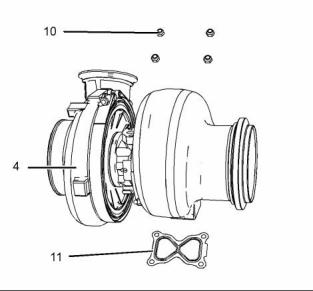

g01382805 |

Illustration 23 |

Typical example |

2. Position a new gasket (11) on the exhaust manifold. |

3. Attach a suitable lifting device to turbocharger (4). The weight of turbocharger is approximately 32 kg (71 lb). Use the lifting device to install the turbocharger to the exhaust manifold. |

g01413397 |

Illustration 24 |

4. Apply Tooling (A) to the threads of the exhaust |

Typical example |

manifold studs. |

6. Follow Steps 6.a through 6.c in order to install the |

tube assembly for the oil drain to the turbocharger. |

5. Install nuts (10). Tighten the nuts to a torque of |

55 N·m (41 lb ft). |

a. Place a new joint (9) and tube assembly (8) in position and install bolts (7) finger tight. |

If a new turbocharger is installed, loosen the V-band clamps and rotate the bearing housing and the compressor housing to the correct positions. |

b. Position a new joint (5) between turbocharger (4) and tube assembly (8). Install bolts (6) finger tight. |

c. Tighten bolts (6) and (7) to a torque of 28 N·m (21 lb ft). |

7. Lubricate the bearings of turbocharger (4) with clean engine oil through oil inlet port (X). Rotate the shaft of the turbocharger in order to distribute the lubricant. |

This document has been printed from SPI². Not for Resale |

400-082-9096

0731-84424871 18374999699

0731-84424872 15580888444

0731-84424873 18274802060

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska