详细描述

John Deere约翰迪尔强鹿柴油发动机冷却系统的维护维修操作技术资料

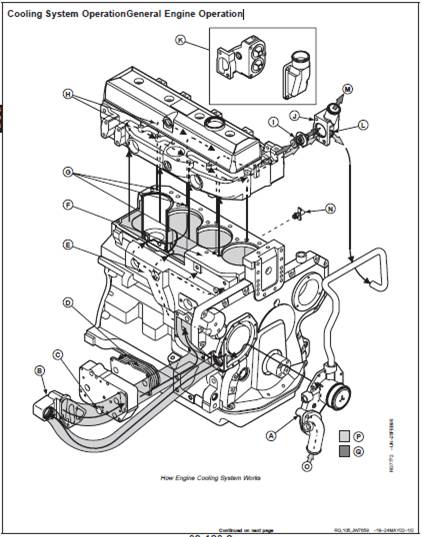

A—Coolant Pump F—Coolant Jacket K—Dual Thermostat Assembly O—Suction Side of Coolant

B—Coolant Passage Adapter G—Block Deck Passages L—Bypass Circuit Pump

C—Oil Cooler Drain Plug H—Passages M—To Radiator Top Tank P—High Temperature Coolant

D—Oil Cooler Plates I—Thermostat(s) N—Drain Valve Q—Low Temperature Coolant

E—Main Coolant Gallery J—Coolant

Manifold/Thermostat

Housing

NOTE: Two-valve head engine shown. Cooling of

four-valve head engine is similar.

The cooling system includes the radiator, coolant

pump (A), and thermostat(s) (I).

Coolant is circulated from the coolant pump into the

coolant passage adapter (B) and circulates around the

oil cooler plates (D). From the oil cooler, coolant flows

into the main coolant gallery (E). From the gallery

coolant flows into the coolant jacket (F), around the

cylinder liners, up through the block deck passages

(G), and into the cylinder head. In the cylinder head,

the coolant flows through passages (H) around the

intake and exhaust ports, valve seats, and injection

nozzles. Coolant flows toward the front end of the

cylinder head and exits through the coolant

manifold/thermostat housing (J). Engines may be

equipped with a dual thermostat assembly (K).

During the warm-up period, thermostat(s) (I) are closed

and coolant is directed through a bypass circuit (L) into

suction side of coolant pump. The coolant continues

circulating through the cylinder block, cylinder head,

and coolant pump to provide a uniform and fast

warm-up period.

Once the engine has reached operating temperature,

the thermostat(s) open and allow coolant to flow

through the upper radiator hose to the radiator top tank

(M). Coolant circulates through the radiator, dissipates

heat, and then flows out of the radiator through the

lower hose and into the suction side (O) of the coolant

pump. Coolant continues flowing through the engine

and radiator circuit until the coolant temperature drops

below the thermostat opening temperature.

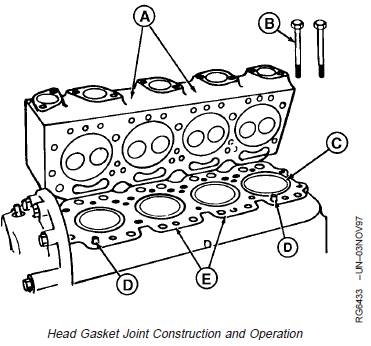

The head gasket joint consists of the following

components:

· Cylinder head gasket

· Cylinder head (A)

· Cylinder block (E)

· Cylinder liners (C)

· Cylinder head cap screws (B)

The head gasket must form an air-tight seal between

cylinder liners and cylinder head that can withstand the

temperatures and pressures of the combustion process.

The gasket must also form a liquid-tight seal between the

cylinder head and cylinder block to retain coolant and oil

in their respective passages. The gasket (F) is

constructed of thin, formed sheets of steel-inserted,

non-asbestos material. The surface of gasket is treated to

improve liquid sealing and anti-stick characteristics. A fire

ring combustion seal (G) is located at each cylinder bore

and is held in place by a U-shaped stainless steel flange

(H).

The cylinder head and block must be flat to provide an

even clamping pressure over the entire surface of gasket,

and must have the proper surface finish to keep gasket

material from moving in the joint. Dowel pins (D) are used

to properly locate head gasket on block.

The cylinder liners must protrude evenly from top of

cylinder block the specified amount to provide adequate

clamping force on fire ring of each cylinder.

The cap screws must be proper length, made of proper

material, and be tightened to proper torque in order to

provide an adequate clamp load between other joint

components.

Each of the above components contributes to the integrity

of the head gasket joint. If any of these components do

not conform to specifications, gasket joint may fail,

resulting in combustion leaks, coolant leaks, or oil leaks.

Head Gasket Joint Construction and

Operation

The head gasket joint consists of the following

components:

· Cylinder head gasket

· Cylinder head (A)

· Cylinder block (E)

· Cylinder liners (C)

· Cylinder head cap screws (B)

The head gasket must form an air-tight seal between

cylinder liners and cylinder head that can withstand the

temperatures and pressures of the combustion process.

The gasket must also form a liquid-tight seal between the

cylinder head and cylinder block to retain coolant and oil

in their respective passages. The gasket (F) is

constructed of thin, formed sheets of steel-inserted,

non-asbestos material. The surface of gasket is treated to

improve liquid sealing and anti-stick characteristics. A fire

ring combustion seal (G) is located at each cylinder bore

and is held in place by a U-shaped stainless steel flange

(H).

The cylinder head and block must be flat to provide an

even clamping pressure over the entire surface of gasket,

and must have the proper surface finish to keep gasket

material from moving in the joint. Dowel pins (D) are used

to properly locate head gasket on block.

The cylinder liners must protrude evenly from top of

cylinder block the specified amount to provide adequate

clamping force on fire ring of each cylinder.

The cap screws must be proper length, made of proper

material, and be tightened to proper torque in order to

provide an adequate clamp load between other joint

components.

Each of the above components contributes to the integrity

of the head gasket joint. If any of these components do

not conform to specifications, gasket joint may fail,

resulting in combustion leaks, coolant leaks, or oil leaks.

Operating conditions such as coolant, oil, and combustion

temperatures, and combustion pressures can reduce the

ability of the head gasket joint to function properly. Failure

of head gasket and mating parts may occur when coolant

and oil temperatures become excessive, or when

abnormally high combustion temperatures and pressures

persist.

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska