详细描述

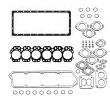

麦克福斯约翰迪尔发动机零配件

约翰迪尔 6081 低压缩活塞

|

| |||||||||||||||||||||||||||

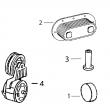

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

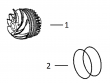

(3)用铝油盘使用TR49377(RE504822)。

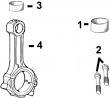

(4)使用TR66452杆式螺栓和机器分体式连杆,并使用带断裂分体式连杆的TR501035杆式螺栓。

(5)发动机ESN 199,999及以下。 仅适用于Exaust Valves。

(6)发动机ESN 200,000及以上。 仅适用于Exaust Valves。

(7)发动机ESN 199,999及以下。

(8)发动机ESN 200,000及以上。

(9)检查应用程序是否正确使用。

(10)机器分体连杆。 使用棒螺栓TR66452。

(11)破裂的分裂连杆。 使用棒螺栓TR501035。

(12)高流量。

(13)与断裂分体连杆一起使用。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE523502、RE518520、RE68345、RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE521538、RE521540、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960

check pilot bearing bore concentricity r22214 –un–14dec88 flywheel bearing bore concentricity 1 mount dial indicator on flywheel housing face and position pointer to contact id of pilot bearing bore in flywheel 2 rotate flywheel by turning crankshaft read total dial indicator movement specification flywheel bearing bore concentricity—maximum variation 0 127 mm (0 005 in ) ctm104 (11jul02) 02-040-19 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=265 crankshaft, main bearings&flywheel 02 040 20 rg,15,dt7452 –19–27mar00–1/1 remove flywheel rg9075 –un–16mar98 remove flywheel rg7518a –un–05nov97 remove flywheel a—guide studs b—jack screw holes caution: flywheel is heavy plan a proper lifting procedure to avoid personal injury 1 remove two cap screws&install guide studs (a) in their place remove the remaining cap screws 2 on flywheels secured with threaded jack screw holes (b): install two jack screws&tighten evenly to remove flywheel 3 on all other flywheels: pry flywheel off of crankshaft note: if flywheel to housing clearance will not allow use of a pry bar, install a punch through timing pin hole&tap on flywheel face to drive from crankshaft ctm104 (11jul02) 02-040-20 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=266 crankshaft, main bearings&flywheel 02 040 21 rg,15,dt7451 –19–14nov97–1/1 replace flywheel ring gear rg7520 –un–05nov97 rg7519 –un–05nov97 flywheel ring gear teeth a—brass drift b—chamfer caution: oil fumes/oil can ignite above 193°c (380°f) use a thermometer&do not exceed 182°c (360°f) do not allow a flame or heating element to be in direct contact with the oil heat the oil in a well ventilated area plan a safe handling procedure to avoid burns 1 place the flywheel on a solid flat surface 2 drive ring gear off with a brass drift (a)&hammer important: if flame heat is used, be sure gear is heated uniformly around circumference do not overheat see caution overheating may also destroy original heat treatment of gear 3 heat new ring gear to 148°c (300°f) using either heated oil, oven heat,/flame heat 4 turn gear so side with chamfer (b) is toward engine with flywheel installed 5 install ring gear against shoulder of flywheel ctm104 (11jul02) 02-040-21 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=267 crankshaft, main bearings&flywheel 02 040 22 rg,15,dt7450 –19–15dec99–1/1 replace pilot bearing in flywheel (if equipped) rg8035 –un–14nov97 flywheel pilot bearing a—bushing driver b—pilot bearing c—flywheel note: some engines are equipped with a pilot bearing (b) in flywheel (c) flywheel must be removed from the engine to replace this bearing 1 with flywheel removed from engine, drive bearing out of flywheel using appropriate disks&driver (a) from d01045aa bushing, bearing&seal driver set discard bearing 2 measure flywheel bore diameter if bore is larger than specifications, replace flywheel specification flywheel pilot bearing bore (option code 1508)—id 34 978—35 004 mm (1 3770—1 3781 in ) flywheel pilot bearing bore (option codes 1502&1515)— id 44 978—45 004 mm (1 7708—1 7719 in ) 3 drive new pilot bearing into rear face of flywheel using appropriate disks&handle from same driver set, until bearing shoulder bottoms on flywheel face check bearing for smooth operation ctm104 (11jul02) 02-040-22 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=268 crankshaft, main bearings&flywheel 02 040 23 rg,15,dt7449 –19–02oct01–1/1 install flywheel rg7518a –un–05nov97 flywheel&guide studs rg10542 –un–19nov99 flywheel (option 1557) rg11778 –un–05sep01 flywheel (option 1568) flexible gasket application pattern a—guide studs b—threaded studs c—flexible gasket pattern caution: flywheel is heavy plan a proper handling procedure to avoid injuries important: flywheel must be clean&free of any oil, grease/debris note: engines with flywheel option code 1557 have threaded studs (b) in flywheel if studs were removed, apply loctite? 271 thread lock and sealer (high strenght) to threads&install studs into flywheel to end of threads cd4045t engines with flywheel option code 1568 must have a continuous 1 5—2 0 mm (0 06—0 08 in ) bead (c) of loctite? 515 flexible form-in-place gasket (ty6304) applied to crankshaft flange around all holes&locating pin 1 install two guide studs (a) in crankshaft cap screw threaded holes place flywheel on studs&slide into position against crankshaft important: always install new flywheel cap screws when flywheel has been removed 2 start cap screws in crankshaft do not tighten until guide studs are removed&all cap screws are started tighten cap screws to specifications specification flywheel mounting cap screws— torque 138 n?m (102 lb-ft) loctite is a registered trademark of loctite corp ctm104 (11jul02) 02-040-23 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=269 crankshaft, main bearings&flywheel 02 040 24 rg,15,dt7448 –19–14nov97–1/1 crankshaft rear oil seal&wear sleeve handling precautions rg5640a –un–31oct97 crankshaft rear oil seal a—wear sleeve use the following precautions for handling seal&wear sleeve assembly (a): ? always install seal&wear sleeve assembly immediately after removal from plastic bag to avoid possible dirt contamination ? no lubrication of any kind is to contact seal when installing use of a lubricant may result in premature seal failure ? install oil seal/wear sleeve assembly with the open side of seal&wear sleeve id chamfer toward the engine if seal is reversed, engine oil may be lost because grooves in oil seal lip would be incorrect with respect to direction of crankshaft rotation rg,15,dt7447 –19–14nov97–1/9 remove crankshaft rear oil seal&wear sleeve rg9083 –un–16mar98 crankshaft rear oil seal&wear sleeve a—oil seal b—wear sleeve the crankshaft rear oil seal (a)&wear sleeve (b) are fabricated as a non-separable part to remove the oil seal/wear sleeve assembly, the two following procedures can be used depending on special tool availability continued on next page ctm104 (11jul02) 02-040-24 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=270 crankshaft, main bearings&flywheel 02 040 25 rg,15,dt7447 –19–14nov97–2/9 rg7399 –un–03nov97 a—forcing screw unitized crankshaft rear oil seal/wear sleeve puller remove oil seal/wear sleeve using jdg698a 1 adjust forcing screw (a) on jdg698a seal&wear sleeve remover&position screw so it centers tool on crankshaft flange 2 using the slots in jdg698a remover as a template, mark three locations on seal casing where screws should be installed for removal purposes remove tool from crankshaft flange rg,15,dt7447 –19–14nov97–3/9 rg7400 –un–23nov97 setting puller removal screws important: holes must be drilled at outer edge of seal case screws will pull seal against wear ring, thereby removing both pieces 3 drill a 3/16 in hole through wear sleeve lip&seal casing at the three marked locations 4 position jdg698a remover on end of crankshaft continued on next page ctm104 (11jul02) 02-040-25 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=271 crankshaft, main bearings&flywheel 02 040 26 rg,15,dt7447 –19–14nov97–4/9 rg7401 –un–03nov97 puller in position b—sheet metal screws 5 install three 2-1/2 in (approximate) sheet metal screws with washers (b) into slots of removal tool&thread screws into holes in seal casing evenly tighten screws until plate is flush with rear face of crankshaft 6 tighten forcing screw (plate should pull evenly against the three screws) until seal&wear sleeve assembly is removed from engine rg,15,dt7447 –19–14nov97–5/9 cd30243 –un–06mar95 rear oil seal/wear sleeve removal remove oil seal/wear sleeve using jdg645e 1 place¢er jdg645e rear crankshaft oil seal/wear sleeve puller cap screws&driver plate assembly onto crankshaft rear face then, using snap ring pliers, set the thinner shoulder of ring tool between sleeve flange&seal case continued on next page ctm104 (11jul02) 02-040-26 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=272 crankshaft, main bearings&flywheel 02 040 27 rg,15,dt7447 –19–14nov97–6/9 cd30244 –un–06mar95 rear oil seal/wear sleeve removal 2 secure the assembly with a clamp, then gradually tighten the screw until wear sleeve is extracted rg,15,dt7447 –19–14nov97–7/9 cd30396 –un–10may95 rear oil seal removal 3 cut the rubber lip (now accessible)&remove it continued on next page ctm104 (11jul02) 02-040-27 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=273 crankshaft, main bearings&flywheel 02 040 28 rg,15,dt7447 –19–14nov97–8/9 cd30397 –un–10may95 rear seal removal 4 using a punch&hammer, tap the seal case toward engine at any location until seal case pivots rg,15,dt7447 –19–14nov97–9/9 cd30247 –un–06mar95 rear oil seal/wear seal removal 5 using jdg22 seal remover, extract seal case ctm104 (11jul02) 02-040-28 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=274 crankshaft, main bearings, &flywheel 02 040 29 dpsg,ouo1004,75 –19–02oct01–1/1 clean&inspect crankshaft flange rg7522 –un–23nov97 clean crankshaft flange 1 clean od of crankshaft flange&id of flywheel housing with cleaning solvent, acetone,/any other suitable cleaner that will remove sealant, if previously applied (brake kleen, ignition cleaner&drier are examples of commercially available solvents that will remove sealant from flange ) 2 look for nicks/burrs on wear ring surface&bore in flywheel housing if necessary, use polishing cloth to remove nicks/burrs finish cleaning by wiping flange with a clean rag rg,15,dt7446 –19–02oct01–1/4 install crankshaft rear oil seal&wear sleeve rg7522 –un–23nov97 clean crankshaft flange important: no lubrication of any kind is to contact seal when installing use of a lubricant may result in premature seal failure install seal&wear sleeve assembly immediately after removal from plastic bag to avoid possible dirt contamination 1 clean od of crankshaft flange&id of flywheel housing with cleaning solvent, acetone,/any other suitable cleaner that will remove sealant, if previously applied (brake kleen, ignition cleaner&drier are examples of commercially available solvents that will remove sealant from flange ) make sure that od of crankshaft flange&id of seal housing bore are free from nicks/burrs 2 the oil seal/wear sleeve assembly can be installed using jt30040b/kcd10002a rear oil seal/wear sleeve installer set ctm104 (11jul02) 02-040-29 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=275 continued on next page crankshaft, main bearings&flywheel 02 040 30 rg,15,dt7446 –19–02oct01–2/4 rg9442 –un–07jul98 rear oil seal/sleeve pilot tool d c rg11779 –un–06sep01 jt30041 modification a—pilot b—cap screws c—locating boss d—crankshaft face jt30041 pilot (early version) install rear oil seal/wear sleeve using jt30040b note: early jt30040 tool set will need a modification to the jt30041 pilot tool remove locating boss (c) flush with crankshaft face (d) add an “a” suffix to the jt30041 tool number (newer tools with “a” suffix do not need to be modified ) 1 install jt30041a pilot (a) from the jt30040b seal/wear sleeve installer set on end of crankshaft using two 38 mm (1-1/2 in ) socket-head cap screws tighten both cap screws until they touch base of pilot, then back them off approximately 1/2 turn 2 install jt30042 driver over jt30041a pilot until driver cross-plate bottoms on pilot this will properly center pilot with crankshaft flange note: it may be necessary to lift up on pilot to install driver to full depth over pilot&crankshaft flange 3 tighten two pilot socket head cap screws (b) securely remove driver from pilot continued on next page ctm104 (11jul02) 02-040-30 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=276 crankshaft, main bearings&flywheel 02 040 31 rg,15,dt7446 –19–02oct01–3/4 rg9443 –un–07jul98 rear oil seal/sleeve driver tool a—driver b—seal important: handle the rear oil seal&sleeve assembly carefully if wear sleeve surface is scratched, gouged/any sealant (liquid) is present, order a new seal assembly 4 carefully start oil seal (b)&wear sleeve over pilot and crankshaft flange with open side of seal toward engine 5 attach jt30042 driver (a)&thrust washer to the guide plate with cap screw tighten the cap screw until driver bottoms on pilot 6 remove seal driver&pilot plate check that seal and wear sleeve assembly is properly positioned on crankshaft flange&installed square in flywheel housing bore continued on next page ctm104 (11jul02) 02-040-31 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=277 crankshaft, main bearings&flywheel 02 040 32 rg,15,dt7446 –19–02oct01–4/4 rg9136 –un–18may98 kcd10002a guide rg9137 –un–18may98 kcd10002a driver a—guide b—driver install rear oil seal/wear sleeve using kcd10002a note: due to a diameter change of the crankshaft bore, it may be necessary to suppress the pilot pin from kcd10002 with this modification, kcd10002 becomes kcd10002a 1 position guide (a) from kcd10002a rear oil seal/wear sleeve installer set on crankshaft end with two cap screws finger tight 2 install new oil seal/wear sleeve assembly on guide with open side of seal toward engine center the guide and tighten cap screws 3 slide driver (b) onto guide (a)&gradually tighten hex nut until driver bottoms on guide 4 remove seal driver&guide check that seal and wear sleeve assembly is properly positioned on crankshaft flange&installed square in flywheel housing bore ctm104 (11jul02) 02-040-32 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=278 crankshaft, main bearings&flywheel 02 040 33 rg,15,dt7445 –19–02oct01–1/1 remove flywheel housing rg10568 –un–10jan00 flywheel housings a—sae 2, 3&4 housing b—standard flat housing c—special flat housing 1 remove flywheel (see remove flywheel earlier in this group ) 2 remove starter if desired (see remove and install starter in group 100) starter and flywheel housing may be removed as an assembly 3 remove crankshaft rear oil seal as described earlier in this group caution: the flywheel housing is heavy plan a proper handling procedure to avoid injuries 4 remove flywheel housing-to-cylinder block cap screws and flywheel housing-to-oil pan cap screws remove flywheel housing from block note: illustration shows three different types of flywheel housings used: ? sae 2, 3,&4 housing (a) ? standard flat housing (b) ? special flat housing (c) some flywheel housings may use a sheet metal plate as part of the enclosure; remove as necessary ctm104 (11jul02) 02-040-33 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=279 crankshaft, main bearings&flywheel 02 040 34 dpsg,ouo1004,1126 –19–19jun02–1/2 remove&install crankshaft timing wheel (two-valve head engines with vp44/de10 fuel injection pumps&all four-valve head engines) rg12028 –un–12dec01 remove timing wheel rg12029 –un–12dec01 timing wheel&crankshaft gear rg12030 –un–12dec01 install timing wheel a—timing wheel b—keyway c—woodruff key d—jdg954-2 adapter (shown) e—jdg954-1 installer important: timing wheel is not reusable if timing wheel is removed from crankshaft, a new timing wheel must be installed note: two-valve head engine shown, four-valve head engine is similar remove timing wheel 1 lock engine at no 1 tdc 2 remove timing gear cover (see remove timing gear cover in group 050 ) 3 clean crankshaft nose note: tapered nose crankshafts must have a thread protector installed in nose before using puller to remove timing wheel 4 remove timing wheel (a) using standard puller as shown install timing wheel note: all other drive gears must be installed before installing timing wheel ensure that the word “front” (stamped on the face of the timing wheel) is facing out from the engine 1 slide timing wheel onto crankshaft nose with recess side toward timing gear cover be sure keyway (b) in timing wheel is properly aligned with woodruff key (c) 2 install tool adapter (d) into nose of crankshaft until adapter seats in bottom of crankshaft use jdg954-2 adapter for straight nose crankshafts/jdg954-7 for tapered nose crankshafts 3 install jdg954-1 installer (e) over adapter ctm104 (11jul02) 02-040-34 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=280 continued on next page crankshaft, main bearings&flywheel 02 040 35 dpsg,ouo1004,1126 –19–19jun02–2/2 4 tighten nut until timing wheel firmly seats against gear face 5 remove adapter&installer&install timing gear cover (see install timing gear cover in group 050 ) rg,15,dt7444 –19–14nov97–1/3 remove crankshaft main bearings 1 drain oil from engine crankcase&remove oil pan 2 remove timing gear cover (see remove timing gear cover in group 050 ) 3 remove cylinder block front plate (see remove cylinder block front plate in group 050 ) 4 remove flywheel housing (see remove flywheel housing in this group ) 5 remove connecting rods from crankshaft (see remove pistons&connecting rods in group 030 ) rg,15,dt7444 –19–14nov97–2/3 rg7525a –un–05nov97 crankshaft main bearing caps a—cast arrows b—stamped numbers important: before removing main bearing caps, check for proper torque on all main bearings note: when crankshaft is to be removed, leave front and rear main bearing caps installed until all connecting rod caps have been removed 6 check main bearing caps for arrows (a) cast in main bearing cap,&numbers (b) stamped on cap&oil pan rail arrow points toward camshaft side of engine if there are no numbers, stamp corresponding numbers on cap&oil pan rail to ensure correct placement of bearing caps during reassembly ctm104 (11jul02) 02-040-35 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=281 continued on next page crankshaft, main bearings&flywheel 02 040 36 rg,15,dt7444 –19–14nov97–3/3 rg7526 –un–05nov97 crankshaft main bearing cap screws c—cap screws 7 remove main bearing caps by extending cap screws (c)&forcing heads of screws together wiggle bearing cap back&forth while applying an upward force with cap screws until free from main bearing cap support important: keep matched bearings with their respective main bearing cap for comparison with crankshaft journal (surface wear) from which removed 8 visually inspect condition of bearing inserts and crankshaft main journals as bearing caps are removed rg,15,dt7443 –19–14nov97–1/1 check main bearing oil clearance rg7528 –un–23nov97 using plastigage note: the use of plastigage? will determine wear (crankshaft-to-bearing oil clearance) but will not determine condition of either bearing/journal surface 1 place a strip of plastigage? in the center of the main bearing cap (with insert) about three-fourths of the width of the bearing/on crankshaft journal to measure oil clearance 2 use clean (sae30) oil on plastigage? to prevent smearing 3 install cap&tighten cap screws to 135 n?m (100 lb-ft) 4 remove cap&compare width of plastigage? with scale provided on wrapper to determine clearance specification crankshaft main bearing-to-journal—oil clearance 0 041—0 109 mm (0 0016—0 0043 in ) plastigage is a registered trademark of the dana corp ctm104 (11jul02) 02-040-36 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=282 crankshaft, main bearings&flywheel 02 040 37 rg,15,dt7442 –19–02oct01–1/2 remove&install crankshaft gear (crankshaft installed in engine) rg7529 –un–05nov97 crankshaft gear puller a—pulling attachment b—push puller note: remove crankshaft gear for replacement only; it is not necessary to remove gear for crankshaft removal remove crankshaft gear 1 lock engine at no 1 tdc compression 2 remove timing gear cover (see remove timing gear cover in group 050 ) 3 remove oil pump (see remove engine oil pump in group 060 ) 4 remove upper idler gear&lower idler gear and shaft (see remove lower&upper idler shafts in group 050 ) 5 remove front plate (see remove cylinder block front plate in group 050 ) note: tapered nose crankshafts must have a thread protector installed in nose before using puller to remove crankshaft gear 6 install no 1123 (d01218aa) pulling attachment (a) or larger onto crankshaft gear 7 install d01200aa push puller (b) remove crankshaft gear continued on next page ctm104 (11jul02) 02-040-37 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=283 crankshaft, main bearings&flywheel 02 040 38 rg,15,dt7442 –19–02oct01–2/2 rg7533 –un–05nov97 crankshaft gear adapter tool rg7534 –un–05nov97 crankshaft gear woodruff key/installer tool a—jdg954-2 adapter shown b—woodruff key c—jdg954-1 installer install crankshaft gear important: if flame heat is used, be sure gear is heated uniformly around circumference do not overheat see caution overheating may also destroy original heat treatment of gear caution: oil fumes/oil can ignite above 193°c (380°f) use a thermometer&do not exceed 182°c (360°f) do not allow a heating element to be in direct contact with the oil heat the oil in a well-ventilated area plan a safe handling procedure to avoid burns 1 heat crankshaft gear to 148°c (300°f) using either heated oil/oven heat 2 install tool adapter (a) into nose of crankshaft until adapter seats in bottom of crankshaft use jdg954-2 adapter for straight nose crankshafts/jdg954-7 for tapered nose crankshafts important: when installing gear, do not gouge or nick crankshaft flange note: chamfered side of gear should be installed toward engine 3 place gear on crankshaft flange be sure woodruff key (b) on crankshaft is properly aligned with keyway in gear 4 install jdg954-1 installer (c) over adapter 5 tighten nut clockwise until gear firmly seats against crankshaft flange allow gear to cool before removing installer 6 refer to appropriate group to complete final assembly of parts removed to access crankshaft gear ctm104 (11jul02) 02-040-38 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=284 crankshaft, main bearings&flywheel 02 040 39 rg,15,dt7441 –19–14nov97–1/1 remove crankshaft rg7535 –un–23nov97 remove crankshaft from cylinder block 1 remove engine front plate (see remove cylinder block front plate in group 050 ) 2 remove flywheel housing&flywheel (see remove flywheel housing earlier in this group ) (see remove flywheel in this group ) 3 remove main bearing caps&connecting rod caps, as described earlier in this group caution: crankshaft is very heavy plan a proper handling procedure to avoid injury 4 attach a lifting sling to crankshaft using proper lifting equipment, carefully raise crankshaft out of cylinder block 5 clean crankshaft, especially oil passages, using solvent&compressed air 6 place crankshaft on clean v-blocks 7 if main bearing inserts are to be replaced, remove inserts from cylinder block otherwise, leave bearing inserts in block until assembled id has been measured ctm104 (11jul02) 02-040-39 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=285 crankshaft, main bearings&flywheel 02 040 40 rg,15,dt7440 –19–14nov97–1/1 inspect crankshaft rg7536b –un–05nov97 crankshaft main bearing journal fillets rgcd7147 –un–30oct97 crankshaft rod bearing journal holes/fillets a—rod journal hole b—journal fillets note: if vibration damper damage was discovered during teardown, it is recommended that the crankshaft be magna-fluxed this will verify whether of not it has microscopic cracks or fissures see inspect vibration damper earlier in this group 1 thoroughly clean crankshaft clear restrictions from all oil passages important: small cracks may not be visible to the eye use a method such as the fluorescent magnetic particle method this method magnetizes the crank, employing magnetic particles which are fluorescent&glow under “black light” the crankshaft must be de-magnetized after inspection 2 inspect crankshaft for signs of load stress, cracks, scoring,/journal scratches replace crankshaft if cracks are found 3 check each journal for evidence of excessive overheating/discoloration if either condition exists, replace crankshaft since heat treatment has probably been destroyed 4 inspect front crankshaft gear for cracks, chipped teeth, or excess wear replace gear as required 5 inspect the keyway for evidence of cracks/wear replace crankshaft as necessary 6 carefully inspect the rear hub of the crankshaft in the area of the wear sleeve contact surface for evidence of a rough/grooved condition any imperfections in this area will result in oil leakage slight ridges may be cleaned up with emery cloth/crocus cloth 7 carefully check the crankshaft for cracks in the area of rod journal holes (a)&at journal fillets (b) replace crankshaft if any cracks are found ctm104 (11jul02) 02-040-40 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=286 crankshaft, main bearings&flywheel 02 040 41 rg,15,dt7439 –19–14nov97–1/1 measure crankshaft journals&main bearing id rg7648 –un–07nov97 measuring main bearing cap id assembly rg7538 –un–05nov97 measuring crankshaft main bearing journal od rg7539 –un–05nov97 measuring crankshaft rod bearing journal od a—main bearing id b—main journal od c—rod journal od 1 with crankshaft removed from engine, assemble main bearing caps with bearing inserts be sure inserts are installed correctly 2 tighten main bearing cap screws to 135 n?m (100 lb-ft) 3 measure&record main bearing assembled id (a) at several points with an inside micrometer 4 measure&record crankshaft main journal od (b) and rod journal od (c) at several points around each journal note: if an undersized crankshaft has been installed, measured dimensions will not meet specifications however, bearing-to-journal oil clearance must be within specification see crankshaft grinding guidelines later in this group 5 compare measurements with specifications given below specification crankshaft main bearing—id 79 391—79 433 mm (3 1256—3 1273 in ) crankshaft main journal—od 79 324—79 350 mm (3 1229—3 1240 in ) crankshaft rod journal—od 77 800—77 826 mm (3 0629—3 0640 in ) crankshaft main bearing-to-journal—oil clearance 0 041—0 109 mm (0 0016—0 0043 in ) crankshaft main/rod journal—maximum taper 0 010 mm (0 0004 in ) crankshaft main/rod journal—maximum out-of-round 0 005 mm (0 0002 in ) replace/recondition crankshaft if it does not fall within above specifications ctm104 (11jul02) 02-040-41 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=287 crankshaft, main bearings&flywheel 02 040 42 rg,15,dt7438 –19–14nov97–1/1 measure main thrust journal width and thrust bearing width rg7540 –un–23nov97 measuring main thrust journal width rg7541 –un–23nov97 measuring main thrust bearing width rg7542 –un–23nov97 assembled main thrust bearing note: if crankshaft has been previously reconditioned, thrust journal width may not be within above specifications however, oil (side) clearance must be within specification 1 measure&record crankshaft main thrust journal width if crankshaft thrust journal width is not within specifications, install a new crankshaft 2 measure&record width of main thrust bearing oil (side) clearance between thrust bearing&thrust journal must be within specifications specification crankshaft main thrust bearing journal (new)—width 38 952—39 028 mm (1 5335—1 5365 in ) crankshaft main thrust bearing— overall width 38 79—38 87 mm (1 527—1 530 in ) ctm104 (11jul02) 02-040-42 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=288 crankshaft, main bearings&flywheel 02 040 43 rg,15,dt7437 –19–20dec99–1/2 crankshaft grinding guidelines rg7536a –un–23nov97 crankshaft main bearing journal fillets rg7542 –un–23nov97 assembled main thrust bearing a—fillets important: crankshaft grinding should be done only by experienced personnel on equipment capable of maintaining crankshaft size&finish specifications undercut&rolled fillets (a) have taken the place of ground (tangential) fillets do not grind within this undercut area when undersize bearings are used crankshafts have micro-finished journal surfaces important: if undersize bearings are installed, recheck bearing-to-journal clearance if oil clearance is not within specifications, premature wear of bearings&journals will result if the crankshaft is to be reground, use the following recommended guidelines: 1 compare the crankshaft journal measurements taken during inspection&determine the size which the journals are to be reground 2 grind all main journals/all connecting rod journals to the same required size important: care must be taken to avoid localized heating which often produces grinding cracks use coolant generously to cool the crankshaft while grinding do not crowd the grinding wheel into the work grind crankshaft with journals turning counterclockwise, as viewed from the front end of the crankshaft lap or polish journals in opposite direction of grinding 3 polish/lap the ground surfaces to the specified finish to prevent excessive wear of the journals 4 stone the edge of all oil holes in the journal surfaces smooth to provide a radius of approximately 1 50 mm (0 060 in ) ctm104 (11jul02) 02-040-43 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=289 continued on next page crankshaft, main bearings&flywheel 02 040 44 rg,15,dt7437 –19–20dec99–2/2 5 when finished grinding, inspect the crankshaft by the fluorescent magnetic particle method,/other similar method to determine if cracks have originated due to the grinding operation 6 de-magnetize the crankshaft after inspection 7 thoroughly clean the crankshaft&oil passages with solvent dry with compressed air rg,15,dt7435 –19–14nov97–1/1 crankshaft grinding specifications bearing size crankshaft main journal od crankshaft rod journal od standard 79 324—79 350 mm 77 800—77 826 mm (3 1229—3 1240 in ) (3 0629—3 0640 in ) 0 25 mm (0 010 in ) undersize 79 074—79 100 mm 77 550—77 576 mm (3 1131—3 1141 in ) (3 0531—3 0541 in ) main&connecting rod journal surface finish (aa) lap 0 20 [micro ]m (8 aa) thrust surface finish (aa) lap 0 40 [micro ]m (16 aa) thrust bearing journal width 38 952—39 028 mm (1 5335—1 5365 in ) direction of crankshaft rotation (viewed from flywheel end): grinding clockwise lapping counterclockwise engine stroke 127 mm (5 00 in ) main journal maximum runout (concentricity) relative to no 1 and no 7 (6 8 l)/no 1&no 5 (4 5 l) journals 0 05 mm (0 0019 in ) main journal maximum runout (concentricity) between adjacent journals 0 025 mm (0 0009 in ) ctm104 (11jul02) 02-040-44 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=290 crankshaft, main bearings&flywheel 02 040 45 rg,15,dt7436 –19–14nov97–1/1 measure assembled id of main bearing caps rg7537 –un–23nov97 measuring assembled main bearing cap id rg7405 –un–03nov97 cylinder block to crankshaft centerline a—top deck-to-centerline bearing bore 1 remove bearing inserts from caps&cylinder block keep inserts in correct order if they are to be reused 2 clean&inspect caps for damage small burrs or nicks on flat surfaces may be removed with a file use a medium-grit polishing cloth to dress curved bearing surfaces 3 install bearing caps (without bearings) in cylinder block tighten cap screws to 135 n?m (100 lb-ft) 4 measure id of bearing cap bores specification crankshaft main bearing bore (without bearings)—id , 84 455—84 481 mm (3 3250—3 3260 in ) crankshaft main bearing bore centerline-to-top deck—distance 337 896—337 972 mm (13 3029—13 3059 in ) important: when cylinder block is line bored, dimension (a) from centerline of main bearing bore to cylinder block top deck will be changed piston may contact cylinder head if this dimension is less than specified above main bearing line boring should be done only by experienced personnel on equipment capable of maintaining bore specifications 5 if bearing caps are damaged/bore is not within specification, install a new cap&line bore to specified size (see measure crankshaft journals&main bearing id, earlier in this group ) note: replacement bearing caps are supplied with unfinished bearing bore ctm104 (11jul02) 02-040-45 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=291 crankshaft, main bearings&flywheel 02 040 46 rg,15,dt7433 –19–14nov97–1/3 install main&thrust bearing inserts in block rg7544 –un–05nov97 a—tang in insert main&thrust bearing insert b—slot in block c—oil holes in insert d—oil passages in block note: lower half of bearing insert with oil hole goes in block 1 install main bearing inserts make sure that tang (a) in insert is engaged with slot (b) in the cylinder block and main bearing caps also make sure oil holes in insert (c) line up with oil passages in block (d) rg,15,dt7433 –19–14nov97–2/3 rg7542a –un–05nov97 a—two-piece bearing assembled main thrust bearing note: only two-piece bearings (a) are provided for service during assembly, apply a liberal coating of clean engine oil to: ? all main bearing webs in block ? both sides of main bearing inserts&thrust bearing inserts ? entire od of crankshaft main bearing journal continued on next page ctm104 (11jul02) 02-040-46 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=292 crankshaft, main bearings&flywheel 02 040 47 rg,15,dt7433 –19–14nov97–3/3 rg7545 –un–05nov97 main thrust bearing b—main thrust bearing 2 install main thrust bearing (b) in thrust web of cylinder block ctm104 (11jul02) 02-040-47 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=293 crankshaft, main bearings&flywheel 02 040 48 rg,15,dt7432 –19–15oct01–1/3 install crankshaft rg7535 –un–23nov97 crankshaft in cylinder block rg7547 –un–05nov97 main bearing insert tangs rg7525b –un–05nov97 bearing cap location&direction stamp a—bearing tang b—stamped numbers c—cast arrow caution: crankshaft is heavy plan a proper lifting procedure to avoid injuries 1 carefully position crankshaft onto main bearing inserts using a hoist&lift sling 2 apply a liberal amount of clean oil to bearing insert dip entire main bearing cap screws in clean engine oil and position them in main bearing caps important: make sure main bearing caps are installed in locations from which they were removed numbers (b) stamped on the caps should match numbers stamped on pan rail of block arrow (c) on cap must point toward camshaft side of block 3 install main bearing caps so bearing tang (a) in cap and cylinder block are together on same side of cylinder block continued on next page ctm104 (11jul02) 02-040-48 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=294 crankshaft, main bearings&flywheel 02 040 49 rg,15,dt7432 –19–15oct01–2/3 rg7548 –un–23nov97 main bearing cap screws important: do not use pneumatic wrench to install main bearing cap screws, as damage may occur to threads 4 tighten all main bearing cap screws to specifications except rear main (thrust) bearing cap screws tighten rear main (thrust) bearing cap screws fingertight specification crankshaft main bearing cap screws—torque 135 n?m (100 lb-ft) important: do not pry on thrust washer when forcing crankshaft back&forth to align thrust bearings 5 before tightening rear main (thrust) bearing cap screws, align upper&lower thrust bearings carefully force crankshaft&main thrust bearing cap to rear, using a prybar between crank throw&block web then, force crankshaft to front to line up thrust bearing surfaces 6 tighten rear main (thrust) bearing cap screws to specified torque specification crankshaft rear main (thrust) bearing cap screws—torque 135 n?m (100 lb-ft) 7 turn crankshaft by hand if crankshaft does not turn easily, disassemble parts&determine the cause continued on next page ctm104 (11jul02) 02-040-49 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=295 crankshaft, main bearings&flywheel 02 040 50 rg,15,dt7432 –19–15oct01–3/3 rg7549 –un–23nov97 connecting rod bearing cap screws important: using pneumatic wrenches to install cap screws may cause damage to the threads never reuse connecting rod cap screws 8 install connecting rod caps&bearings install new cap screws&tighten to specification (see install piston&connecting rod assembly in group 030 ) 9 check crankshaft for specified end play specification crankshaft—end play 0 029—0 357 mm (0 001—0 014 in ) ctm104 (11jul02) 02-040-50 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=296 crankshaft, main bearings&flywheel 02 040 51 rg,15,dt7431 –19–11jun02–1/3 install flywheel housing rg10544 –un–03dec99 flywheel housing rg10545 –un–03dec99 flywheel housing (t06068tf151) rg12413 –un–10jul02 a—o-ring 1 inspect&clean cylinder block&flywheel housing mating surfaces using a brass scraper and/or steam cleaner remove any previously applied sealant or gasket material 2 rinse well with plain water to remove all soap residue from gasket surfaces note: some flywheel housings may use a impregnated gasket instead of sealant do not apply sealant to gasket/mating surfaces of these housings if equipped, locate camshaft o-ring seal (a) in recess similar to recess shown in bottom figure check parts catalog for specific engine applications 3 install new camshaft o-ring seal (a) (if equipped) important: surfaces to be bonded must be free of oil, dirt,/cleaning agents 4 apply loctite? 515 (ty6304) flexible form-in-place gasket in a continuous 2—4 mm (0 080—0 157 in ) bead to flywheel housing as shown note: in middle figure for t06068tf151 engine, note that bead between no 1&no 2 cap screw is centered on rib of housing? centerline to cap screw holes locate bead in the center of mating surfaces as shown and completely encircle cap screws (except no 3) and dowel holes loctite is a registered trademark of loctite corp continued on next page ctm104 (11jul02) 02-040-51 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=297 crankshaft, main bearings&flywheel 02 040 52 rg,15,dt7431 –19–11jun02–2/3 rg12371 –un–31may02 3210, 3310&3410 tractor torque sequence important: tighten cap screws to specifications in sequence shown, within 10 minutes after parts are assembled engines equipped with a dual starter flywheel housing require a matching flywheel if replacing single starter housing with a dual, the flywheel must also be changed note: on 6103, 6203, 6403&6603 tractors: apply loctite? 515 (ty6304) flexible form-in-place gasket to flywheel housing surface under head of m20 cap screw on camshaft side of engine (position no 4 in upper figure) on 3210, 3310,&3410 tractors: lubricate flywheel housing cap screws with clean engine oil before assembly 5 install flywheel housing on cylinder block&tighten cap screws to specifications specification flywheel housing cap screws— torque 125 n?m (92 lb-ft) 3210, 3310&3410 tractor—specification flywheel housing cap screws (1—8)—torque 110 n?m (81 lb-ft) flywheel housing cap screws (9 and 12)—torque 130 n?m (96 lb-ft) flywheel housing cap screws (13&14)—torque 280 n?m (206 lb-ft) flywheel housing cap screws (10&11)—torque 530 n?m (391 lb-ft) 6 check flywheel housing seal bore runout (concentricity) if runout exceeds specification, replace housing specification flywheel housing seal bore— maximum permissible runout (concentricity) 0 152 mm (0 006 in ) 7 install crankshaft rear oil seal assembly (see install crankshaft rear oil seal&wear sleeve earlier in this group ) loctite is a registered trademark of loctite corp ctm104 (11jul02) 02-040-52 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=298 continued on next page crankshaft, main bearings&flywheel 02 040 53 rg,15,dt7431 –19–11jun02–3/3 8 if torque converter access hole plug was removed, apply loctite? 277 to plug&install note: some flywheel housings may use a sheet metal plate as part of the enclosure, install as necessary loctite is a registered trademark of loctite corp ctm104 (11jul02) 02-040-53 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=299 crankshaft, main bearings&flywheel 02 040 54 rg,15,dt7430 –19–19jun02–1/1 complete final assembly use new gaskets&o-rings during final engine assembly clean all engine components as necessary prior to assembly 1 install oil bypass valve assembly in front face of block (see remove, inspect&install oil bypass valve in group 060) 2 install front plate (see install cylinder block front plate in group 050 ) 3 install balancer shafts (if equipped) (see install and time balancer shafts in group 050 ) 4 install timing gear train&camshaft (see install camshaft in group 050 ) 5 install oil pump assembly (see install engine oil pump in group 060 ) 6 if equipped with cartridge type oil pressure regulating valve, install valve (see remove and install oil pressure regulating valve in group 060 ) 7 install timing gear cover gasket&timing gear cover (see install timing gear cover in group 050 ) 8 if equipped with spring, plunger&seat type oil pressure regulating valve, install valve assembly (see remove&install oil pressure regulating valve in group 060 ) 9 install front oil seal (see replace front crankshaft oil seal&wear sleeve in this group ) 10 install oil pan (see install oil pan in group 060 ) 11 install crankshaft pulley,/vibration damper (see install pulley/vibration damper and pulley in this group ) 12 install push rods,&rocker arm assembly (see install rocker arm assembly in group 020 ) 13 install fuel supply pump see section 02, group 090 of ctm207 (mechanical fuel systems), ctm170 (level 4 electronic fuel systems), ctm331 (level 12 electronic fuel systems), ctm284 (level 1 electronic fuel systems) or ctm220 (level 11 electronic fuel systems with denso high pressure common rail) 14 install injection pump see section 02, group 090 of ctm207 (mechanical fuel systems), ctm170 (level 4 electronic fuel systems), ctm331 (level 12 electronic fuel systems), ctm284 (level 1 electronic fuel systems)/ctm220 (level 11 electronic fuel systems with denso high pressure common rail) 15 install starter motor (see remove and install starter in group 100 ) 16 adjust valve clearance (see check and adjust valve clearance in group 020 for two-valve head engines/check&adjust valve clearance in group 21 for four-valve head engines ) 17 install&adjust poly-vee belts (see group 070 ) 18 fill engine with clean oil&proper coolant (see section 01, group 002) 19 perform engine break-in (see perform engine break-in in group 010 ) ctm104 (11jul02) 02-040-54 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=300 group 050 camshaft, balancer shafts&timing gear train 02 050 1 rg,16,dt7507 –19–23may02–1/2 measure valve lift rg7550 –un–23nov97 two-valve head engine shown rg12165a –un–03jul02 four-valve head engine shown important: for a more accurate measurement, measure valve lift at 0 00 mm (0 00 in ) rocker arm-to-valve tip clearance note: measuring valve lift provides an indication of wear on camshaft lobes&camshaft followers/push rods 1 remove heat shield if required 2 remove rocker arm cover 3 using jde81-1/jde83 flywheel turning tool and jdg1571/jde81-4 timing pin inserted in flywheel, lock no 1 piston at tdc compression stroke see check&adjust valve clearance in group 020 for engine valve locations 4 set rocker arm-to-valve tip clearance to 0 00 mm (0 00 in ) for: ? no 1&3 exhaust&no 1&2 intake valves on 4-cylinder engines ? no 1, 3,&5 exhaust&no 1, 2,&4 intake valves on 6-cylinder engines 5 on two-valve head engine: place dial indicator tip on top of valve rotator as shown preload indicator tip and set dial at 0 0 mm (0 00 in ) 6 on four-valve head engine: place dial indicator tip on top of valve bridge as shown preload indicator tip and set dial at 0 0 mm (0 00 in ) 7 remove timing pin from flywheel&manually rotate engine one full revolution (360°) in running direction 8 observe dial indicator reading as valve is moved to full open record maximum reading&compare with specifications two-valve head engines—specification intake valves—valve lift [at 0 00 mm (0 00 in ) valve clearance] 11 77—12 21 mm (0 463—0 481 in ) wear limit 11 34 mm (0 447 in ) ctm104 (11jul02) 02-050-1 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=301 continued on next page camshaft, balancer shafts&timing gear train 02 050 2 rg,16,dt7507 –19–23may02–2/2 exhaust valves—valve lift [at 0 00 mm (0 00 in ) valve clearance] 11 51—11 94 mm (0 453—0 470 in ) wear limit 11 08 mm (0 436 in ) four-valve head engines—specification intake valves—valve lift [at 0 00 mm (0 00 in ) valve clearance] 9 03—9 43 mm (0 356—0 371 in ) wear limit 8 7 mm (0 343 in ) exhaust valves—valve lift [at 0 00 mm (0 00 in ) valve clearance] 9 32—9 72 mm (0 367—0 383 in ) wear limit 9 00 mm (0 354 in ) 9 if valve lift on all valves is within specifications, adjust valve lash to specified clearance (see check and adjust valve clearance in group 020 ) if valve lift on one/more valves is not within specification, remove&inspect entire valve train and camshaft 10 rotate engine one full revolution (360°) lock engine at: ? tdc no 4 compression stroke for 4-cylinder engines ? tdc no 6 compression stroke for 6-cylinder engines 11 set rocker arm-to-valve tip clearance to 0 0 mm (0 00 in ) for: ? no 2&4 exhaust&no 3&4 intake valves on 4-cylinder engines ? no 2, 4,&6 exhaust&no 3, 5,&6 intake valves on 6-cylinder engines 12 repeat steps 4—7 ctm104 (11jul02) 02-050-2 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=302 camshaft, balancer shafts&timing gear train 02 050 3 rg,16,dt7506 –19–23may02–1/4 remove timing gear cover rg7590a –un–05jan98 oil cooler-to-water manifold elbow (two-valve head engine shown) rg7937a –un–13nov97 fan belt, tensioner&alternator (two-valve head engine shown) rg7953 –un–13nov97 water pump, fan&crankshaft pulley (two-valve head engine shown) a—oil cooler-to-water manifold elbow b—fan belt tensioner c—fan belt d—alternator e—water pump f—fan pulley g—crankshaft pulley/damper note: it is not necessary to remove belt tensioner (two-valve head engines&some four-valve head engines), water pump pulley/water pump when removing timing gear cover important: whenever the aluminum timing gear cover/water pump are replaced, the cooling system should be flushed and serviced see flush&service cooling system in section 01, group 002 ensure system, including radiator, is completely drained 1 drain oil from engine crankcase 2 remove fan 3 remove oil pan 4 remove oil cooler-to-water manifold elbow (a) at front plate 5 release fan belt tensioner (b)&remove fan belt (c) 6 on four-valve head engines: if needed remove fan belt tensioner&bracket as an assembly 7 remove alternator (d)&alternator mounting bracket (see remove&install alternator in group 100 ) 8 on non-auxiliary drive engines, remove tensioner bracket 9 remove water pump (e), if desired (see remove water pump in group 070 ) 10 remove fan pulley (f) 11 remove crankshaft pulley/damper (g) (see remove pulley/vibration damper and pulley in group 040 ) 12 remove unitized front oil seal/wear sleeve, if equipped (see replace front crankshaft oil seal&wear sleeve in group 040 ) ctm104 (11jul02) 02-050-3 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=303 continued on next page camshaft, balancer shafts&timing gear train 02 050 4 rg,16,dt7506 –19–23may02–2/4 rg7551a –un–05nov97 adjustable fan drive assembly (two-valve head engine shown) a—adjustable fan drive 13 remove adjustable fan drive assembly (a) (see remove&inspect fan drive assembly in group 070 ) rg,16,dt7506 –19–23may02–3/4 rg8047 –un–05jan98 remove oil pressure regulating valve plug (early two-valve head engines only) rg8048 –un–05jan98 oil pressure regulating valve (early two-valve head engines only) 14 on two-valve head engines: unscrew oil pressure regulating valve plug, if required remove spring and valve (see remove&install oil pressure regulating valve in group 060 ) 15 remove auxiliary drive cover&gears, if equipped, as described later in this group (see remove and install camshaft gear-driven auxiliary drive later in this group ) ctm104 (11jul02) 02-050-4 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=304 continued on next page camshaft, balancer shafts&timing gear train 02 050 5 rg,16,dt7506 –19–23may02–4/4 rg9105 –un–01apr98 two-valve head engine shown rg12353a –un–03jul02 four-valve head engine shown a—stud nuts&washers b—cap screws c—cap screws d—stud nuts&washers e—cap screw (behind engine front plate) note: mark&identify location of timing gear cover hardware before removal to aid in reassembly 16 on later, two-valve head engines:1 remove timing gear cover-to-cylinder block stud nuts&washers (a) 17 on all engines: remove timing gear cover-to-cylinder block stud nuts&washers (d) 18 on two-valve head engines: remove cap screws (b) 19 remove cap screws (c) bordering timing cover and cap screw (e) on back of engine front plate remove cover 20 remove two piece oil seal/wear sleeve, if equipped (see replace front crankshaft oil seal and wear sleeve in group 040 ) 1serial numbers: dubuque-built engines (703905— ), saran-built engines (516218— ), torreon-built engines (001000— ) ctm104 (11jul02) 02-050-5 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=305 camshaft, balancer shafts&timing gear train 02 050 6 rg,16,dt7505 –19–17oct01–1/4 remove&install camshaft bushing with front plate installed note: a camshaft bushing is installed in front (no 1) camshaft bore only the front plate has a chamfered edge allowing camshaft bushing removal&installation with the front plate installed remove camshaft bushing 1 set engine at no 1 tdc compression 2 on turbocharged engines, disconnect the turbocharger oil inlet line , (see disconnect turbocharger oil inlet line in group 010 ) 3 remove timing gear cover, as described earlier in this group (see remove timing gear cover in this group ) 4 remove rocker arm cover&rocker arm assembly (see remove cylinder head in group 020 or 021 ) 5 remove push rods&identify location for reinstallation 6 on engines with camshaft driven fuel supply pump, see remove fuel supply pump in section 02, group 090 of ctm207 (mechanical fuel systems), remove fuel supply pump in section 02, group 090 of ctm331 (level 12 electronic fuel systems with stanadyne de10 pump),/remove mechanical fuel transfer pump in section 02, group 090 of ctm220 (level 11 electronic fuel systems with denso high pressure common rail) continued on next page ctm104 (11jul02) 02-050-6 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=306 camshaft, balancer shafts&timing gear train 02 050 7 rg,16,dt7505 –19–17oct01–2/4 rg7556a –un–05nov97 camshaft follower holder kit a—magnetic follower holder kit 7 revolve engine to an angle where camshaft followers fall away from camshaft/use d15001nu magnetic follower holder kit (a) to hold followers continued on next page ctm104 (11jul02) 02-050-7 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=307 camshaft, balancer shafts&timing gear train 02 050 8 rg,16,dt7505 –19–17oct01–3/4 rg7557 –un–05nov97 front plate on cylinder block rg7558 –un–05nov97 camshaft bushing removal tool a—cap screw b—jdg739-7 tapered bottom leg (8 mm) c—jdg739-3 removing/installing plate d—jdg739-4 bushing installer screw 8 remove camshaft (see remove camshaft later in this group ) important: engine must remain in a position where camshaft followers rest against cylinder head/are held in up position by magnetic holders so that followers do not fall into engine crankcase if camshaft followers fall into crankcase, cylinder head removal will be required 9 remove countersunk torx? cap screw (a) install jdg739-7 (m8 x 1 25) tapered bottom leg (b) from jdg739b camshaft bushing service kit into hole that has chamfered screw&star washer important: block must be replaced if camshaft bore is damaged be careful when removing/installing bushing 10 install jdg739-8 (m8 x 1 25) flat bottom legs and jdg739-3 removing/installing plate (c) to cylinder block so plate is parallel with front plate¢ered over camshaft bore tighten legs&hex nuts securely important: cylinder block bore may be damaged if puller is not properly piloted in bushing be sure puller is properly piloted before pulling bushing 11 insert jdg739-1 bushing remover into camshaft bore so puller pilots in bushing id&jdg739-4 bushing installer screw (d) extends through plate 12 install thrust washer&hex nut tighten hex nut until bushing is free of block bore remove puller and discard bushing 13 clean&inspect bore in cylinder block if bore is damaged, replace cylinder block torx is a registered trademark of camcar/textron ctm104 (11jul02) 02-050-8 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=308 continued on next page camshaft, balancer shafts&timing gear train 02 050 9 rg,16,dt7505 –19–17oct01–4/4 rg7559 –un–05nov97 camshaft bushing oil hole alignment rg7560 –un–05nov97 camshaft bushing installation tool a—bushing b—jdg739-5b bushing installer c—oil supply hole install camshaft bushing important: bushings must be installed so oil supply hole in bushing aligns with oil drilling in block bore 1 mark orientation of oil supply hole (c) on front face of block&on bushing to help with bushing alignment during installation 2 apply ty6333 high-temperature grease to id&od of new bushing (a),&to id of bushing bore slide bushing onto jdg739-5b bushing installer (b) so notched end of bushing will be toward front end of engine when installed 3 thread jdg739-4 bushing installer screw into jdg739-3 removing/installing plate with bushing started, square in bore&oil hole aligned, tighten forcing screw until flange of bushing driver bottoms against face of block 4 remove bushing tool from cylinder block&check oil supply hole for correct alignment if holes are not aligned, remove&discard bushing install a new bushing ctm104 (11jul02) 02-050-9 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=309 camshaft, balancer shafts&timing gear train 02 050 10 rg,16,dt7504 –19–14nov97–1/1 remove&install camshaft gear-driven auxiliary drive rg9049 –un–16mar98 auxiliary drive a—gear cover b—auxiliary drive assembly note: various auxiliary drive options are available; removal&installation of all options are similar the auxiliary drive is integrated into the engine front timing gear cover 1 remove lube line 2 remove auxiliary drive gear cover (a) 3 clean&inspect cover for cracks/damage 4 remove auxiliary drive assembly (b) note: auxiliary drive assembly is repairable refer to ctm67, oem acces***ies, for additional service information 5 inspect for cracked housing, worn/damaged bearings, damaged gear/spline 6 repair/replace auxiliary drive assembly as needed 7 install gasket on auxiliary drive assembly&position in the cylinder block plate install cap screws and tighten to specifications specification auxiliary drive-to-cylinder block plate—torque 95 n?m (70 lb-ft) 8 install cover&tighten cap screws/nuts to specifications specification auxiliary drive cover plate— torque 55 n?m (41 lb-ft) 9 install lube line ctm104 (11jul02) 02-050-10 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=310 camshaft, balancer shafts&timing gear train 02 050 11 rg,16,dt7503 –19–14nov97–1/1 measure camshaft end play rg7561 –un–23nov97 measuring camshaft end play measure camshaft end play specification camshaft—end play 0 08—0 23 mm (0 003—0 009 in ) if end play is excessive, check thrust plate thickness with camshaft removed (see measure camshaft thrust plate clearance&thickness, later in this group ) rg,16,dt7502 –19–14nov97–1/1 measure balancer shaft end play (if equipped—4-cylinder engines) rg7702 –un–23nov97 measuring balancer shaft end play—4-cylinder measure balancer shaft end play specification balancer shaft—end play 0 05—0 26 mm (0 002—0 010 in ) if balancer shaft end play exceeds specifications, check thrust plate thickness (see inspect balancer shaft gears&thrust plates, later in this group ) ctm104 (11jul02) 02-050-11 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=311 camshaft, balancer shafts&timing gear train 02 050 12 rg,16,dt7501 –19–14nov97–1/1 measure idler gear end play rg7562 –un–23nov97 measuring idler gear end play check end play of upper&lower idler gears specification upper idler gear—end play 0 070—0 170 mm (0 0027—0 0066 in ) lower idler gear—end play 0 070—0 330 mm (0 0027—0 0129 in ) if idler gear end play does not meet specifications, check idler gear, idler shaft,&thrust washer for wear (see measure idler gear bushing&shaft later in this group ) ctm104 (11jul02) 02-050-12 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=312 camshaft, balancer shafts&timing gear train 02 050 13 rg,16,dt7500 –19–17oct01–1/1 measure timing gear backlash rg7530 –un–05nov97 6-cylinder engine (two-valve head engine shown) rg7703b –un–07nov97 4-cylinder engine (two-valve head engine shown) a—camshaft gear-to-upper idler gear b—injection pump gear-to-upper idler gear c—upper idler gear-to-crankshaft gear d—crankshaft gear-to-lower idler gear e—oil pump gear-to-lower idler gear f—balancer shaft gear-to-oil pump gear g—lower idler gear-to-balancer shaft gear note: all gears have helical cut teeth measure timing gear backlash compare against the following specifications timing gear backlash specifications—specification camshaft-to-upper idler (a) (two-valve head engine)— backlash 0 04—0 2 mm (0 0015—0 008 in ) camshaft-to-upper idler (a) (four-valve head engine)— backlash 0 03—0 64 mm (0 0011—0 0254 in ) injection pump-to-upper idler (b) (two-valve head engine)— backlash 0 04—0 2 mm (0 0015—0 008 in ) injection pump-to-upper idler (b) (four-valve head engine)— backlash 0 09—0 55 mm (0 0034—0 0218 in ) upper idler-to-crankshaft (c) (two-valve head engine)— backlash 0 04—0 2 mm (0 0015—0 008 in ) upper idler-to-crankshaft (c) (four-valve head engine)— backlash 0 09—0 55 mm (0 0034—0 0218 in ) crankshaft-to-lower idler (d)— backlash 0 07—0 60 mm (0 0027—0 0236 in ) oil pump-to-lower idler (e)— backlash 0 08—0 60 mm (0 0031—0 0236 in ) balancer shaft-to-oil pump (4-cyl only) (f)—backlash 0 06—0 65 mm (0 0025—0 0255 in ) lower idler-to-balancer shaft (4-cyl only) (g)—backlash 0 07—0 65 mm (0 0027—0 0255 in ) camshaft-to-auxiliary drive (not shown)—backlash 0 05—0 68 mm (0 0021—0 0266 in ) ctm104 (11jul02) 02-050-13 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=313 camshaft, balancer shafts&timing gear train 02 050 14 rg,16,dt7499 –19–17oct01–1/5 remove camshaft note: it is not necessary to remove cylinder head from engine for camshaft removal if push rods are bent/show excessive scuffing, it may be necessary to remove cylinder head for inspection of block, head&camshaft followers (see remove cylinder head in group 020 or 021 ) new service camshafts have fixed gears camshaft&gear are replaced as an assembly 1 drain engine oil&coolant, if not previously done 2 measure valve lift (see measure valve lift, earlier in this group) 3 remove rocker arm assembly&push rods (see remove cylinder head in group 020 ) 4 remove timing gear cover (see remove timing gear cover, earlier in this group ) rg,16,dt7499 –19–17oct01–2/5 rg9050 –un–16mar98 fuel supply pump a—cap screws 5 remove cap screws (a)&camshaft activated fuel supply pump see remove fuel supply pump in section 02, group 090 of ctm207 (mechanical fuel systems), remove fuel supply pump in section 02, group 090 of ctm331 (level 12 electronic fuel systems with stanadyne de10 pump)/remove mechanical fuel transfer pump in section 02, group 090 of ctm220 (level 11 electronic fuel systems with denso high pressure common rail) continued on next page ctm104 (11jul02) 02-050-14 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=314 camshaft, balancer shafts&timing gear train 02 050 15 rg,16,dt7499 –19–17oct01–3/5 rg7564 –un–05nov97 camshaft gear a—cap screws 6 rotate engine gear train until cap screws (a) can be removed rg,16,dt7499 –19–17oct01–4/5 rg7556b –un–05nov97 magnetic camshaft follower holder kit rg7563 –un–05nov97 fuel supply pump actuator pin b—pump actuator pin c—magnetic follower holder kit important: engine must remain in a position where camshaft followers rest against cylinder head/are held in up position with magnetic holders so that followers do not fall into engine crankcase if camshaft followers fall into crankcase, cylinder head removal is required note: d15001nu magnetic follower holder kit (c) may also be used to hold camshaft followers away from lobes 7 revolve engine on repair stand to an angle where camshaft followers&fuel supply pump actuator pin (b) falls away from camshaft lobes important: do not allow camshaft lobes to drag in bushing/honed bores 8 carefully pull camshaft straight up, out of cylinder block note: rotate camshaft carefully to aid in removing ctm104 (11jul02) 02-050-15 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=315 continued on next page camshaft, balancer shafts&timing gear train 02 050 16 rg,16,dt7499 –19–17oct01–5/5 rg7565 –un–05nov97 camshaft&thrust plate a—thrust plate 9 remove thrust plate (a) from slot behind camshaft gear rg,16,dt7498 –19–14nov97–1/1 visually inspect camshaft rg3500 –un–03nov97 camshaft lobe inspection a—lobes b—journal 1 clean camshaft in solvent dry with compressed air 2 inspect all camshaft lobes (a)&journals (b) for wear or damage replace camshaft as necessary 3 inspect camshaft for broken, cracked/excessively worn drive gear replace camshaft as necessary important: new camshaft followers can be used with old camshaft do not reuse old camshaft followers with a new camshaft note: very light score marks are acceptable if valve lift is within specification if pitting/galling exists, replace camshaft (see measure valve lift earlier in this group ) ctm104 (11jul02) 02-050-16 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=316 camshaft, balancer shafts&timing gear train 02 050 17 rg,16,dt7514 –19–15nov97–1/1 measure camshaft thrust plate clearance and thickness rg7120 –un–23nov97 measuring camshaft thrust plate clean camshaft thrust plate&check clearance using a feeler gauge replace parts as necessary specification camshaft thrust plate— clearance 0 08—0 23 mm (0 003—0 009 in ) note: thrust plate clearance determines camshaft end play check thrust plate thickness specification camshaft thrust plate— thickness 3 96—4 01 mm (0 156—0 158 in ) ctm104 (11jul02) 02-050-17 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=317 camshaft, balancer shafts&timing gear train 02 050 18 rg,16,dt7497 –19–14nov97–1/1 inspect&measure camshaft bushing id and journal od rg7566 –un–23nov97 measuring camshaft journal od all engine camshafts have a (replaceable) bushing installed in no 1 (front) camshaft bore 1 measure camshaft journals if a camshaft journal is damaged/does not meet specification, install a new camshaft 2 measure camshaft bushing id&remaining bores in cylinder block if camshaft bore is damaged/is not within specification, have a qualified machine shop install new bushings if no 1 camshaft bushing id does not meet specifications, replace camshaft bushing (see remove&install camshaft bushing earlier in this group ) camshaft bearing bores&journals—specification camshaft journal—od 55 872—55 898 mm (2 1997—2 2007 in ) camshaft bore, front no 1 in block (without bushing)—id 59 961—59 987 mm (2 3607—2 3617 in ) camshaft bore, front no 1 in block (with bushing)—id 55 961—55 987 mm (2 2031—2 2042 in ) camshaft bore, all except no 1—id 55 986—56 012 mm (2 2042—2 2052 in ) camshaft journal-to-bushing, no 1 bore (with bushing)—oil clearance 0 063—0 115 mm (0 0025—0 0045 in ) camshaft journal-to-bushing, all except no 1 bore—oil clearance 0 088—0 140 mm (0 0035—0 0055 in ) ctm104 (11jul02) 02-050-18 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=318 camshaft, balancer shafts&timing gear train 02 050 19 rg,16,dt7496 –19–14nov97–1/1 measure camshaft lobe height rg7567 –un–05nov97 measuring camshaft lobe height a—high point b—narrow point 1 measure each camshaft lobe at highest point (a) and at narrowest point (b) the difference between these dimensions is camshaft lobe height if height is not within specification on any lobe, install a new camshaft specification camshaft intake lobe (two-valve head engines)—height 7 05—7 31 mm (0 278—0 288 in ) camshaft intake lobe (four-valve head engines)— height 5 88—6 14 mm (0 231—0 242 in ) camshaft exhaust lobe (two-valve head engines)— height 6 89—7 15 mm (0 271—0 281 in ) camshaft exhaust lobe (four-valve head engines)— height 5 84—6 10 mm (0 230—0 240 in ) 2 measure fuel supply pump camshaft lobe diameter if diameter is not within specification/lobe surface is grooved, install a new camshaft specification fuel supply pump camshaft lobe (early)—diameter 41 15—41 41 mm (1 62—1 63 in ) fuel supply pump camshaft lobe (late)—diameter 42 67—42 93 mm (1 68—1 69 in ) rg,16,dt7495 –19–14nov97–1/1 inspect camshaft gear important: camshaft must be replaced if dropped or damaged camshaft gear&shaft key are no longer available as service parts if gear is damaged, replace camshaft&gear as an assembly 1 clean camshaft&gear in solvent dry with compressed air 2 inspect camshaft gear for nicks&scratches replace camshaft&gear assembly if damage is found ctm104 (11jul02) 02-050-19 powertech? 4 5 l & 6 8 l diesel engines 071102 pn=319 camshaft, balancer shafts&timing gear train 02 050 20 rg,16,dt7494 –19–14nov97–1/1 inspect camshaft followers rg6324 –un–23nov97 camshaft follower note: cylinder head must be removed before camshaft followers can be removed from engine (see remove cylinder head in group 020 or 021 ) 1 inspect followers for uneven wear/damage also inspect corresponding camshaft lobe for wear or damage replace as necessary 2 measure follower od&follower bore id in cylinder block specification camshaft follower—od 31 61—31 64 mm (1 245—1 246 in ) camshaft follower bore in block—id 31 70—31 75 mm (1 248—1 250 in ) 日喀则岗巴县帕金斯发动机配件中心库是那家批发商,吴忠利通美国爱科(AGCO)拖拉机珀金斯柴油机销售销售公司,楚雄牟定县康明斯k38发动机配件的地方在那?,安庆潜山县奥林匹亚GEP100-400KW发电机规格资料的地方在那?,六盘水水城县CAT卡特空气滤芯6I2509费用报价单,