详细描述

麦克福斯约翰迪尔发动机零配件

约翰迪尔 4045 4.5T/H 活塞(米) RE515037 排放 2 & 3

|

| ||||||||||||||||||||||||||||

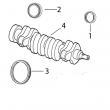

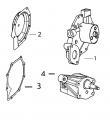

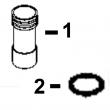

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确操作。

(3)锥形鼻子。

(4)直鼻。

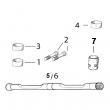

(5)检查应用程序是否正确使用。

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

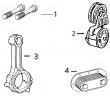

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE69781、RE50809、RE64243、RE507959、RE506544、RE504063、SE501235、RE504067、RE547892、AR2643、RE41956、RE539769、RE505475、SE500804、RE522964、AR2643、RE69791、SE501268、EDG-01V-H-1-PNT11-5115-R、A45-F-F-04-H/

强鹿JOHNDEERE起动机及起动马达常见型号:

RE523502、RE59588、RE540301、RE528929、RE515843、RE515895、RE507670、RE70957、RE70957、RE70960、RE508322、RE504009、RE70474、RE70960、RE523501、RE507943、RE528929、RE507236、RE528532、RE68470、RE51447、RE54092、RE505745、RE503226、RE509025、RE540301 SE501419、SE501844、RE520437re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505702) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507326 engine controller 1 (b) (marked re507980) focus (12v) re507327 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1659 pn=149 p r o o f p r o o f fuel injection 16j2 16j2 16j2 16j2 16j2 16j2 rgp7411 -un-15aug01 this parts listing is continued 1600-1660 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=150 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507328 engine controller 1 (b) (marked re507980) focus (12v) re507329 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1661 pn=151 p r o o f p r o o f fuel injection 16j3 16j3 16j3 16j3 16j3 16j3 rgp7411 -un-15aug01 this parts listing is continued 1600-1662 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=152 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507348 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1663 pn=153 p r o o f p r o o f fuel injection 16j4 16j4 16j4 16j4 16j4 16j4 rgp7411 -un-15aug01 this parts listing is continued 1600-1664 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=154 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507349 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1665 pn=155 p r o o f p r o o f fuel injection 16l1 16l1 16l1 16l1 16l1 16l1 rgp7411 -un-15aug01 this parts listing is continued 1600-1666 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=156 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31719 electronic unit injector 6 (a) (marked re504092) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507330 engine controller 1 (b) (marked re507980) focus (12v) re507331 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1667 pn=157 p r o o f p r o o f fuel injection 16l2 16l2 16l2 16l2 16l2 16l2 rgp7411 -un-15aug01 this parts listing is continued 1600-1668 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=158 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31719 electronic unit injector 6 (a) (marked re504092) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507332 engine controller 1 (b) (marked re507980) focus (12v) re507333 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1669 pn=159 p r o o f p r o o f fuel injection 16l3 16l3 16l3 16l3 16l3 16l3 rgp7411 -un-15aug01 this parts listing is continued 1600-1670 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=160 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31719 electronic unit injector 6 (a) (marked re504092) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507350 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1671 pn=161 p r o o f p r o o f fuel injection 16l4 16l4 16l4 16l4 16l4 16l4 rgp7411 -un-15aug01 this parts listing is continued 1600-1672 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=162 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31719 electronic unit injector 6 (a) (marked re505430) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507351 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1673 pn=163 p r o o f p r o o f fuel injection 163a 163a 163a 163a 163a 163a rgp7411 -un-15aug01 this parts listing is continued 1600-1674 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=164 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507360 engine controller 1 (b) (marked re507980) focus (12v) re507361 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1675 pn=165 p r o o f p r o o f fuel injection 163b 163b 163b 163b 163b 163b rgp7411 -un-15aug01 this parts listing is continued 1600-1676 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=166 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507362 engine controller 1 (b) (marked re507980) focus (12v) re507363 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1677 pn=167 p r o o f p r o o f fuel injection 163c 163c 163c 163c 163c 163c rgp7411 -un-15aug01 this parts listing is continued 1600-1678 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=168 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507380 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1679 pn=169 p r o o f p r o o f fuel injection 163d 163d 163d 163d 163d 163d rgp7411 -un-15aug01 this parts listing is continued 1600-1680 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=170 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507381 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1681 pn=171 p r o o f p r o o f fuel injection 164a 164a 164a 164a 164a 164a rgp7411 -un-15aug01 this parts listing is continued 1600-1682 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=172 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507364 engine controller 1 (b) (marked re507980) focus (12v) re507365 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1683 pn=173 p r o o f p r o o f fuel injection 164b 164b 164b 164b 164b 164b rgp7411 -un-15aug01 this parts listing is continued 1600-1684 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=174 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507366 engine controller 1 (b) (marked re507980) focus (12v) re507367 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1685 pn=175 p r o o f p r o o f fuel injection 164c 164c 164c 164c 164c 164c rgp7411 -un-15aug01 this parts listing is continued 1600-1686 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=176 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507382 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1687 pn=177 p r o o f p r o o f fuel injection 164d 164d 164d 164d 164d 164d rgp7711 -un-08jun01 this parts listing is continued 1600-1688 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=178 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507383 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1689 pn=179 p r o o f p r o o f fuel injection 164j 164j 164j 164j 164j 164j rgp7411 -un-15aug01 this parts listing is continued 1600-1690 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=180 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507400 engine controller 1 (b) (marked re507980) focus (12v) re507401 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1691 pn=181 p r o o f p r o o f fuel injection 164k 164k 164k 164k 164k 164k rgp7411 -un-15aug01 this parts listing is continued 1600-1692 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=182 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg30742 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507402 engine controller 1 (b) (marked re507980) focus (12v) re507403 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1693 pn=183 p r o o f p r o o f fuel injection 164l 164l 164l 164l 164l 164l rgp7411 -un-15aug01 this parts listing is continued 1600-1694 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=184 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507418 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1695 pn=185 p r o o f p r o o f fuel injection 164m 164m 164m 164m 164m 164m rgp7411 -un-15aug01 this parts listing is continued 1600-1696 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=186 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507419 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600-1697 pn=187 p r o o f p r o o f fuel injection memoranda memoranda memoranda memoranda memoranda memoranda 1600-1738 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=188 p r o o f p r o o f fuel injection sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp7248 -un-31jan01 165a - 165a - 165c - 165d - 165j - 165k - 165l - 165m - 166a - 166b - 166c - 166d - 166j - 166k - 166l - 166m - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600aa-a01 pn=189 p r o o f p r o o f fuel injection sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 165a - 165a - 165c - 165d - 165j - 165k - 165l - 165m - 166a - 166b - 166c - 166d - 166j - 166k - 166l - 166m - 1600aa-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) pn=190 p r o o f p r o o f fuel injection memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 1600a-1601 pn=191 p r o o f p r o o f fuel injection 165a 165a 165a 165a 165a 165a rgp7411 -un-15aug01 this parts listing is continued 1600a-1602 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=192 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507368 engine controller 1 (b) (marked re507980) focus (12v) re507369 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1603 pn=193 p r o o f p r o o f fuel injection 165b 165b 165b 165b 165b 165b rgp7411 -un-15aug01 this parts listing is continued 1600a-1604 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=194 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507370 engine controller 1 (b) (marked re507980) focus (12v) re507371 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur, bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1605 pn=195 p r o o f p r o o f fuel injection 165c 165c 165c 165c 165c 165c rgp7411 -un-15aug01 this parts listing is continued 1600a-1606 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=196 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507384 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1607 pn=197 p r o o f p r o o f fuel injection 165d 165d 165d 165d 165d 165d rgp7411 -un-15aug01 this parts listing is continued 1600a-1608 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=198 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507385 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1609 pn=199 p r o o f p r o o f fuel injection 165j 165j 165j 165j 165j 165j rgp7411 -un-15aug01 this parts listing is continued 1600a-1610 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=200 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505430) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507404 engine controller 1 (b) (marked re507980) focus (12v) re507405 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1611 pn=201 p r o o f p r o o f fuel injection 165k 165k 165k 165k 165k 165k rgp7411 -un-15aug01 this parts listing is continued 1600a-1612 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=202 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505430) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507406 engine controller 1 (b) (marked re507980) focus (12v) re507407 engine controller 1 (c) (marked re507982) focus (12v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) low temperature basse temperature niedrige temperatur bassa temperatura temperatura baja laag temperatur (c) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta hoeg temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1613 pn=203 p r o o f p r o o f fuel injection 165l 165l 165l 165l 165l 165l rgp7411 -un-15aug01 this parts listing is continued 1600a-1614 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=204 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505430) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507420 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1615 pn=205 p r o o f p r o o f fuel injection 165m 165m 165m 165m 165m 165m rgp7411 -un-15aug01 this parts listing is continued 1600a-1616 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=206 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505207) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507421 engine controller 1 (b) (marked re507981) focus (24v) (a) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad (b) high temperature temperature elevee hohe temperatur alta temperatura temperatura alta heog temperatur powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 1600a-1617 pn=207 p r o o f p r o o f fuel injection 166a 166a 166a 166a 166a 166a rgp7411 -un-15aug01 this parts listing is continued 1600a-1618 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) pn=208 p r o o f p r o o f fuel injection engine key part no. part name qty serial no. remarks 1 re500292 wiring harness 1 -030292 (sub re508984) re508984 wiring harness 1 030293- 2 r56461 o-ring 1 3 19m7864 screw 5 m8 x 12 4 r128315 clamp 5 5 r134920 nut 12 6 r502172 socket 6 7 r502173 clip 6 8 r133655 pad 6 9 r133651 packing 6 10 r502703 packing 6 11 r502171 packing 6 12 rg31717 electronic unit injector 6 (a) (marked re505702) 13 sleeve 6 (option 5100) 14 o-ring 6 (option 5100) 15 r501390 cap screw 6 m8 x 50 16 r116054 clamp 6 -014584 (sub r505747) r505747 clamp 6 014585- 17 r124676 bracket 1 18 19m7865 screw 2 19 re507372 engine controller 1 (b) (marked re507980) focus (12v) re507373 engine controller 1 (c) (marked 嘉定康明斯发动机博士柴油泵大家推荐的日昕-英珀威,陇南礼县P558250唐纳森滤清器的价格多少?,固原泾源县306-9199柴油滤芯联系方式?,防城港上思县卡特彼勒柴油泵提供在线购买,昆明石林帕金斯水泵多少钱解决方案?,安顺普定县沃尔沃发动机上止推片的价格多少?,内蒙古自治锡林郭勒正镶白旗珀金斯柴油发动机4008TAG2A配件销售认准指定代理商,河北衡水阜城县威尔逊柴油发电机原厂进口配件解决方案?,湛江吴川三菱S6R2-PTA-C油封有哪些,安庆宜秀perkins船用发动机配件提供在线购买,西安未央perkins1104德尔福燃油泵纯正配件的批发商,rg,ctm67,g50,8 –19–27oct93–2/2 rg6909 –un–17aug93 a—bearing cup b—snap ring 5. evenly drive one bearing cup (a) out of housing bore. 6. remove snap ring (b)&press remaining bearing cup out of housing bore. discard bearing cups and snap ring. 7. clean&inspect parts&compare to the following specifications: specification output housing bore (right-hand or left-hand drive)—id 65.049—65.075 mm (2.5610—2.5620 in.) . output shaft (right-hand or left-hand drive)—od 34.954—34.969 mm (1.3761—1.3767 in.) . bearing cup—od 65.088—65.113 mm (2.5625—2.5635 in.) bearing cone—id 34.925—34.938 mm (1.3750—1.3755 in.) . retaining collar—id 34.847—34.873 mm (1.3719—1.3730 in.) rg,ctm67,g50,10 –19–27oct93–1/2 assemble right-hand output gear assembly rg6909 –un–17aug93 a—bearing cup b—snap ring important: bearings are damaged during disassembly. always install new bearings in a matched set. note: snap ring, spacer ring, bearing cups,&bearing cones are provided in a matched set to maintain correct bearing clearance when assembled. 1. install snap ring (b) into housing groove. 2. press small i.d. end of bearing cup into gear end of housing bore until seated against snap ring. 3. support the first bearing cup. press small i.d. end of second bearing cup (a) into opposite end of housing bore until firmly seated against snap ring. ctm67 (24sep02) 50-6 oem engine acces***ies 092402 pn=308 continued on next page auxiliary drive, 6076 (500000— ) 50 7 rg,ctm67,g50,10 –19–27oct93–2/2 rg6908 –un–17aug93 a—oil restriction fitting b—retaining collar c—bearing cone d—spacer ring e—bearing cone f—output gear important: do not press on roller bearing retainer. press only on inner race of bearing cone. 4. press bearing cone (e) onto output gear (f) so large end of cone is toward the gear. 5. install gear&bearing assembly into housing. install spacer ring (d) over shaft. 6. support gear&housing assembly on face of gear. press small end of second bearing cone (c) onto shaft until tight against spacer ring. 7. press collar (b) onto shaft (part number side facing outward) until seated solid against bearings. 8. check bearing clearance by rotating gear. gear must rotate freely. 9. using a new gasket, install oil restriction orifice fitting (a) in housing. rg,ctm67,g50,12 –19–27oct93–1/2 install right-hand output gear assembly rg6897 –un–17aug93 a—button head cap screws b—camshaft gear c—auxiliary drive gear note: four button head cap screws (a) without washers are used in place of 12-point cap screws with washers on the injection pump drive gear to provide clearance for the auxiliary drive gear. 1. using a new gasket, install auxiliary drive assembly into timing gear cover. auxiliary drive gear (c) must be meshed with camshaft gear (b). ctm67 (24sep02) 50-7 oem engine acces***ies 092402 pn=309 continued on next page auxiliary drive, 6076 (500000— ) 50 8 rg,ctm67,g50,12 –19–27oct93–2/2 rg6898 –un–17aug93 a—cap screw b—output gear note: apply loctite 242 thread lock&sealer on threads of cap screw (a). 2. install drive housing mounting cap screws, oil lines, and clamp. tighten cap screws to specifications. specification right-hand output housing-to-timing gear cover (3/8 in.)—torque . 27 n?m (20 lb-ft) 3. check output gear (b)-to-camshaft gear backlash and compare to following specifications. specification right-hand output gear-to-camshaft gear— backlash 0.11—0.7 mm (0.004—0.028 in.) . rg,ctm67,g50,13 –19–27oct93–1/1 remove left-hand output gear assembly rg6899 –un–17aug93 a—oil line b—cap screws 1. remove oil line (a)&output housing-to-idler housing cap screws (b). 2. remove housing&gear assembly from idler housing. discard gasket. ctm67 (24sep02) 50-8 oem engine acces***ies 092402 pn=310 auxiliary drive, 6076 (500000— ) 50 9 rg,ctm67,g50,15 –19–27oct93–1/2 disassemble left-hand output gear assembly rg6931 –un–23aug93 a—retaining collar b—bearing cone c—spacer ring d—oil restriction fitting e—bearing cone f—output gear 1. remove&inspect oil restriction orifice fitting (d). note: bearings will be damaged during disassembly and cannot be reused. 2. support gear side of housing in a press. 3. push on end of shaft to remove collar (a), bearing cone (b),&gear from housing. 4. remove other bearing cone (e) from gear (f). discard bearings&spacer ring (c). continued on next page ctm67 (24sep02) 50-9 oem engine acces***ies 092402 pn=311 auxiliary drive, 6076 (500000— ) 50 10 rg,ctm67,g50,15 –19–27oct93–2/2 rg6930 –un–23aug93 a—bearing cup b—snap ring c—bearing cup 5. evenly drive one bearing cup (a) out of housing bore. 6. remove snap ring (b)&press remaining bearing cup (c) out of housing bore. discard bearing cups and snap ring. 7. clean&inspect parts. compare to the following specifications: specification output housing bore (right-hand or left-hand drive)—id 65.049—65.075 mm (2.5610—2.5620 in.) . output shaft (right-hand or left-hand drive)—od 34.954—34.969 mm (1.3761—1.3767 in.) . bearing cup—od 65.088—65.113 mm (2.5625—2.5635 in.) bearing cone—id 34.925—34.938 mm (1.3750—1.3755 in.) . retaining collar—id 34.847—34.873 mm (1.3719—1.3730 in.) ctm67 (24sep02) 50-10 oem engine acces***ies 092402 pn=312 auxiliary drive, 6076 (500000— ) 50 11 rg,ctm67,g50,17 –19–27oct93–1/2 assemble left-hand output gear assembly rg6932 –un–23aug93 a—bearing cup b—snap ring c—bearing cup important: bearings are damaged during disassembly. always install new bearings in a matched set. note: snap ring, spacer ring, bearing cups,&bearing cones are provided in a matched set to maintain correct bearing clearance when assembled. 1. install snap ring (b) into housing groove. 2. press small i.d. end of bearing cup (a) into gear end of housing bore until seated against snap ring. 3. support the first bearing cup. press small i.d. end of second bearing cup (c) into opposite end of housing bore until firmly seated against snap ring. continued on next page ctm67 (24sep02) 50-11 oem engine acces***ies 092402 pn=313 auxiliary drive, 6076 (500000— ) 50 12 rg,ctm67,g50,17 –19–27oct93–2/2 rg6931 –un–23aug93 a—retaining collar b—bearing cone c—spacer ring d—oil restriction fitting e—bearing cone f—output gear important: roller bearing retainer can be easily damaged. do not press on retainer. press only on inner race of bearing cone. 4. press bearing cone (e) onto gear (f) so large end of cone is toward the gear. 5. install gear&bearing assembly into housing. install spacer ring (c) over shaft. 6. support gear&housing assembly on face of gear. press small end of second bearing cone (b) onto shaft until tight against spacer ring. 7. press collar (a) onto shaft (part number side facing outward) until seated solid against bearings. 8. check bearing clearance by rotating gear. gear must rotate freely. 9. using a new gasket, install oil restriction orifice fitting (d) in housing. ctm67 (24sep02) 50-12 oem engine acces***ies 092402 pn=314 auxiliary drive, 6076 (500000— ) 50 13 rg,ctm67,g50,18 –19–27oct93–1/1 remove left-hand rear adapter housing rg6934 –un–23aug93 a—gasket b—adapter housing remove hex nuts&rear adapter housing (b). discard gasket (a). rg,ctm67,g50,25 –19–27oct93–1/4 remove idler housing&idler gear rg6900 –un–05dec97 a—timing cover cap screws b—idler housing cap screws c—button head cap screw 1. remove vibration damper. (see engine repair manual.) 2. loosen idler housing cap screws (b)&timin, g gear cove, r cap screws (a). 3. remove large button head cap screw (c). continued on next page ctm67 (24sep02) 50-13 oem engine acces***ies 092402 pn=315 auxiliary drive, 6076 (500000— ) 50 14 rg,ctm67,g50,25 –19–27oct93–2/4 rg6901 –un–05dec97 a—idler shaft 4. use d01209aa slide hammer&puller to pull idler shaft (a) loose from cylinder block. remove shaft and o-ring from housing. 5. inspect shaft&compare to the following specification: specification idler gear shaft—od 24.367—24.383 mm (0.9593—0.9600 in.) rg,ctm67,g50,25 –19–27oct93–3/4 rg6902 –un–05dec97 a—face seal b—timing cover cap screw 6. remove idler housing cap screws&timing gear cover cap screw (b). note: face seal (a) can be reused if not damaged. use care when removing idler housing from timing gear cover. 7. lift idler housing&gear out of timing gear cover opening. remove face seal&o-ring. rg,ctm67,g50,25 –19–27oct93–4/4 rg6904 –un–05dec97 a—cap screw b—housing bore 8. remove cap screw (a). slide idler gear out of housing. 9. remove o-ring from housing bore (b). ctm67 (24sep02) 50-14 oem engine acces***ies 092402 pn=316 auxiliary drive, 6076 (500000— ) 50 15 rg,ctm67,g50,26 –19–27oct93–1/1 replace idler gear bearing rg6928 –un–05dec97 a—outer bearing support b—idler bearing c—idler gear d—inner bearing support e—threaded hole 1. remove inner (d)&outer (a) bearing supports. 2. support gear&bearing assembly on face of gear. press on outer race of bearing (b) to remove bearing from gear (c). 3. clean&inspect parts&compare to the following specifications: specification idler gear—id 114.940—114.976 mm (4.5252—4.5266 in.) . idler gear bearing—od 114.985—115.000 mm (4.5270—4.5276 in.) id 74.985—75.000 mm (2.9522—2.9528 in.) . inner idler bearing support—od 74.973—74.991 mm (2.9517—2.9524 in.) id 24.402—24.418 mm (0.9607—0.9613 in.) . important: press only on outer race of bearing to avoid damaging bearing. 4. press bearing into gear until bearing is flush with face of gear. 5. install inner&outer bearing supports so idler shaft bores&cap screw holes align. note: inner idler bearing support has one threaded hole (e). ctm67 (24sep02) 50-15 oem engine acces***ies 092402 pn=317 auxiliary drive, 6076 (500000— ) 50 16 rg,ctm67,g50,31 –19–27oct93–1/6 install idler housing&idler gear rg6904 –un–05dec97 a—cap screw with seal b—housing bore 1. grease&install o-ring in housing bore (b). note: inner idler bearing support has one threaded hole, and is installed toward block side of housing. 2. install idler gear into idler housing. install cap screw with seal (a) to hold idler gear in place. rg,ctm67,g50,31 –19–27oct93–2/6 rg6903 –un–05dec97 a—o-ring groove 3. insert idler shaft through idler housing&idler gear until flush with block side of housing. important: white dot on one end of shaft must face out toward front of engine. 4. grease o-ring groove (a) in back side of idler housing. insert o-ring. rg,ctm67,g50,31 –19–27oct93–3/6 rg6905 –un–05dec97 a—gauge hole note: face seal may be reused if it is not cut, nicked, or damaged. 5. using a short guide stud, place face seal on timing gear cover opening. gauge hole (a) must be positioned toward bottom of opening. continued on next page ctm67 (24sep02) 50-16 oem engine acces***ies 092402 pn=318 auxiliary drive, 6076 (500000— ) 50 17 rg,ctm67,g50,31 –19–27oct93–4/6 rg6935 –un–08dec97 rg6900 –un–05dec97 a—timing gear cover cap screws b—idler housing cap screws c—large button head cap screw d—o-ring e—back-up ring important: be careful not to damage face seal or displace o-ring on back side of idler housing during assembly. 6. carefully insert idler gear into opening of timing gear cover until idler gear meshes with crankshaft gear, and housing is seated against face seal. push idler shaft into block. 7. check condition of o-ring (d)&back-up ring (e) on large button head cap screw (c). grease o-ring and install cap screw through idler shaft. thread into block until finger tight. 8. remove guide stud. install timing gear cover cap screws (a)&idler housing cap screws (b) finger tight. note: middle timing gear cover cap screw must have a seal. continued on next page ctm67 (24sep02) 50-17 oem engine acces***ies 092402 pn=319 auxiliary drive, 6076 (500000— ) 50 18 rg,ctm67,g50,31 –19–27oct93–5/6 rg6906 –un–05dec97 9. tighten cap screws to specifications in the following sequence: ? idler housing-to-timing gear cover (1,2): specification idler housing-to-timing gear cover (3/8 in.):—torque 41 n?m (30 lb-ft) ? idler housing-to-cylinder block (3): 3/8 inch cap screws: specification idler housing-to-cylinder block (3/8 in.)—torque . 41 n?m (30 lb-ft) ? idler housing-to-cylinder block (4): 1/2 inch cap screws: specification idler housing-to-cylinder block (1/2 in.)—torque . 102 n?m (75 lb-ft) ? idler shaft (5): specification idler shaft and housing-to-cylinder block (5/8 in.)—torque. 150 n?m (110 lb-ft) ? timing gear cover-to-cylinder block (6,7,8): specification timing gear cover-to-block (3/8 in.)—torque. 27 n?m (20 lb-ft) ? idler housing-to-idler bearing (9): specification idler housing-to-idler bearing (5/16 in.)—torque . 27 n?m (20 lb-ft) ctm67 (24sep02) 50-18 oem engine acces***ies 092402 pn=320 continued on next page auxiliary drive, 6076 (500000— ) 50 19 rg,ctm67,g50,31 –19–27oct93–6/6 10. check idler gear-to-crankshaft gear backlash. backlash must be as follows: specification idler gear-to-crankshaft gear— backlash 0.11—0.7 mm (0.004—0.028 in.) . 11. install vibration damper. (see engine repair manual.) rg,ctm67,g50,32 –19–27oct93–1/1 install left-hand output gear assembly rg6907 –un–17aug93 a—oil supply line b—output housing cap screws c—spline teeth 1. install new gasket onto pilot of output housing. 2. insert output gear assembly into front opening of idler gear housing. tighten cap screws (b) to specifications. specification left-hand output housing-to-idler housing (3/8 in.)—torque. 41 n?m (30 lb-ft) 3. check output gear (c)-to-idler gear backlash. backlash must as follows: specification left-hand output gear-to-idler gear—backlash 0.08—0.74 mm (0.003—0.029 in.) . 4. install oil supply line (a) on orifice fitting. 5. if front drive is not used, install front cover&gasket. tighten cap screws to specifications specification air compres*** drive cover-to-idler housing (3/8 in.)— torque . 41 n?m (30 lb-ft) ctm67 (24sep02) 50-19 oem engine acces***ies 092402 pn=321 auxiliary drive, 6076 (500000— ) 50 20 rg,ctm67,g50,33 –19–27oct93–1/1 install left-hand rear adapter housing rg6933 –un–23aug93 a—idler gear housing b—studs c—gasket d—adapter housing 1. install new gasket (c) onto pilot of adapter housing (d). note: apply loctite 242 thread lock&sealer to threads of studs (b). 2. install adapter housing on rear of idler gear housing (a). tighten cap screws to specifications. specification left-hand rear adapter housing-to-idler housing (1/2 in.)—torque. 102 n?m (75 lb-ft) 3. if rear drive is not used, install rear cover&gasket. tighten cap screws to specifications. specification air compres*** drive cover-to-idler housing (3/8 in.)— torque . 41 n?m (30 lb-ft) ctm67 (24sep02) 50-20 oem engine acces***ies 092402 pn=322 group 51 auxiliary drive (2.9 l) 51 1 dpsg,ouo1030,39 –19–19mar99–1/1 auxiliary drive (2.9 l) specifications item measurement specification right hand auxiliary drive gear nut torque 55 n?m (41 lb-ft) acces***y-to-timing gear cover torque 50 n?m (35 lb-ft) cap screws&nuts dpsg,ouo1030,17 –19–12mar99–1/1 remove&install right-hand auxiliary drive cd30354 –un–03feb93 cd30613 –un–16jun98 a—gear b—gear retaining nut c—mounting cap screw&nut note: two acces***y mounting cap screws pass through timing gear cover. 1. remove cap screws&nuts (c). remove acces***y with gear. 2. if gear replacement is necessary, remove nut (b), washer&gear (a) from acces***y shaft. 3. install gear (a), washer&nut (b) on acces***y shaft. tighten to specifications. if equipped, bend tabs of washer up against nut. specification right hand auxiliary drive gear nut—torque 55 n?m (41 lb-ft) 4. install acces***y with gasket on engine (arrow). 5. install cap screws&nuts. tighten to specifications. specification acces***y-to-timing gear cover cap screws&nuts—torque 50 n?m (35 lb-ft) ctm67 (24sep02) 51-1 oem engine acces***ies 092402 pn=323 auxiliary drive (2.9 l) 51 2 ctm67 (24sep02) 51-2 oem engine acces***ies 092402 pn=324 group 52 auxiliary drive (4.5 l&6.8 l) 52 1 dpsg,ouo1030,40 –19–19mar99–1/1 auxiliary drive (4.5 l&6.8 l) specifications item measurement specification auxiliary drive-to-cylinder block torque 95 n?m (70 lb-ft) plate auxiliary drive cover plate torque 55 n?m (41 lb-ft) offset auxiliary drive-to-cylinder torque 95 n?m (70 lb-ft) block plate offset auxiliary drive gear cover torque 55 n?m (41 lb-ft) plate offset auxiliary drive cover plate torque 55 n?m (41 lb-ft) dpsg,ouo1030,18 –19–12mar99–1/1 remove&install auxiliary drive rg9049 –un–16mar98 a—gear cover b—auxiliary drive assembly 1. remove lube line. 2. remove auxiliary drive gear cover (a). 3. remove auxiliary drive assembly (b). 4. inspect for cracked housing, worn/damaged bearings, damaged gear/spline. 5. install new gasket on auxiliary drive assembly and position in cylinder block plate. install cap screws and tighten to specifications. specification auxiliary drive-to-cylinder block plate—torque 95 n?m (70 lb-ft) 6. install new gasket&cover. tighten cap screws to specifications. specification auxiliary drive cover plate— torque . 55 n?m (41 lb-ft) 7. install lube line. ctm67 (24sep02) 52-1 oem engine acces***ies 092402 pn=325 auxiliary drive (4.5 l&6.8 l) 52 2 dpsg,ouo1030,19 –19–12mar99–1/1 remove&install offset auxiliary drive rg9509 –un–17mar99 a—m10x25 cap screw (2 used) b—m12x110 cap screw (2 used) c—nut (2 used) 1. remove lube line. 2. remove nuts (c)&auxiliary drive gear cover. 3. remove cap screws (a&b)&remove offset drive and cover. 4. inspect for cracked housing, worn/damaged gears or spline. 5. install new gasket on auxiliary drive assembly and position on cylinder block plate. 6. install o-ring, gear cover&cap screws (a)&(b). tighten to specifications. specification offset auxiliary drive-to-cylinder block plate (b)—torque 95 n?m (70 lb-ft) specification offset auxiliary drive gear cover plate (a)—torque . 55 n?m (41 lb-ft) 7. install o-ring, drive cover plate&nuts (c). tighten to specifications. specification offset auxiliary drive cover plate (c)—torque. 55 n?m (41 lb-ft) ctm67 (24sep02) 52-2 oem engine acces***ies 092402 pn=326 auxiliary drive (4.5 l&6.8 l) 52 3 dpsg,ouo1030,20 –19–15mar99–1/1 disassemble&inspect auxiliary drive adapter rg9510 –un–17mar99 a—housing b—bearing c—gear d—drive shaft 1. remove bearing (b), gear (c)&drive shaft (d) from housing (a). 2. inspect for worn/damaged components. if components are worn/damaged, complete replacement of gear drive adapter is necessary. dpsg,ouo1030,21 –19–15mar99–1/1 disassemble&inspect offset auxiliary drive adapter rg9511 –un–17mar99 a—housing d—drive shaft g—drive shaft i—snap ring b—gear e—bearing h—bearing j—gear c—spacer f—gear note: components (g—j) are on spline drive adapters only. 1. remove parts (g—j) from housing (a). 2. inspect for worn/damaged components. if components are worn/damaged, complete replacement of offset drive gear adapter is necessary. ctm67 (24sep02) 52-3 oem engine acces***ies 092402 pn=327 auxiliary drive (4.5 l&6.8 l) 52 4 ctm67 (24sep02) 52-4 oem engine acces***ies 092402 pn=328 group 53 auxiliary drive (8.1 l) 53 1 dpsg,ouo1030,49 –19–26mar99–1/1 auxiliary drive (8.1 l) specifications item measurement specification idler gear housing mounting cap torque see installation procedure in this screws group. right-hand output gear assembly torque 27 n?m (20 lb-ft) output gear-to-camshaft gear backlash 0.11—0.7 mm (0.004—0.028 in.) left-hand rear adapter torque 102 n?m (75 lb-ft) housing-to-auxiliary drive housing idler shaft torque 150 n?m (110 lb-ft) timing gear cover-to-cylinder block torque 27 n?m (20 lb-ft) idler gear-to-crankshaft gear backlash 0.11—0.70 mm (0.004—0.028 in.) front cover cap screws torque 41 n?m (30 lb-ft) left-hand output gear housing cap torque 41 n?m (30 lb-ft) screws output gear-to-idler gear backlash 0.08—0.74 mm (0.003—0.029 in.) ctm67 (24sep02) 53-1 oem engine acces***ies 092402 pn=329 auxiliary drive (8.1 l) 53 2 dpsg,ouo1030,22 –19–15mar99–1/1 remove right-hand output gear assembly rg9506 –un–19mar99 a—cap screw (6 used) 1. remove oil line&clamp. 2. remove drive housing mounting cap screws (a). 3. remove drive assembly from timing gear cover. discard gasket. dpsg,ouo1030,23 –19–15mar99–1/2 disassemble right-hand output gear assembly rg6908 –un–17aug93 a—oil restriction fitting b—retaining collar c—bearing cone d—spacer ring e—bearing cone f—output gear 1. remove&inspect oil restriction orifice fitting (a). note: bearings will be damaged during disassembly and cannot be reused. 2. support gear side of housing in a press. 3. push on end of shaft to remove collar (b), bearing cone (c)&gear from housing. 4. remove other bearing cone (e) from gear (f). discard bearings&spacer ring (d). ctm67 (24sep02) 53-2 oem engine acces***ies 092402 pn=330 continued on next page auxiliary drive (8.1 l) 53 3 dpsg,ouo1030,23 –19–15mar99–2/2 rg6909 –un–17aug93 a—bearing cup b—snap ring 5. evenly drive one bearing cup (a) out of bore. 6. remove snap ring (b)&press remaining bearing cup out of housing bore. discard bearing cups and snap ring. dpsg,ouo1030,24 –19–15mar99–1/2 assemble right-hand output gear assembly rg6909 –un–17aug93 a—bearing cup b—snap ring important: bearings are damaged during disassembly. always install new bearings in a matched set. note: snap ring, spacer ring, bearing cups&bearing cones are provided in a matched set to maintain correct bearing clearance when assembled. 1. install snap ring (b) into housing groove. 2. press small id end of bearing cup into gear end of housing bore until seated against snap ring. 3. support the first bearing cup. press small id end of second bearing cup (a) into opposite end of housing bore until firmly seated against snap ring. continued on next page ctm67 (24sep02) 53-3 oem engine acces***ies 092402 pn=331 auxiliary drive (8.1 l) 53 4 dpsg,ouo1030,24 –19–15mar99–2/2 rg6908 –un–17aug93 a—oil restriction fitting b—retaining collar c—bearing cone d—spacer ring e—bearing cone f—output gear important: do not press on roller bearing retainer. press only on inner race of bearing cone. 4. press bearing cone (e) onto output gear (f) so large end of cone is toward the gear. 5. install gear&bearing assembly into housing. install spacer ring (d) over shaft. 6. support gear&housing assembly on face of gear. press small end of second bearing cone (c) onto shaft until against spacer ring. 7. press collar (b) onto shaft (part number side facing outward) until seated solid against bearings. 8. check bearing clearance by rotating gear. gear must rotate freely. 9. using a new gasket, install oil restriction fitting (a) in housing. ctm67 (24sep02) 53-4 oem engine acces***ies 092402 pn=332 auxiliary drive (8.1 l) 53 5 dpsg,ouo1030,25 –19–15mar99–1/1 install right-hand output gear assembly rg9527 –un–24mar99 a—cap screw b—output gear note: four button head cap screws without washers are used in place of 12-point cap screws with washers on the injection pump drive gear to provide clearance for the auxiliary drive gear. 1. using a new gasket, install auxiliary drive assembly into timing gear cover. auxiliary drive gear must be meshed with camshaft gear. note: apply loctite?242 thread lock&sealer on threads of cap screw (a). 2. install drive housing mounting cap screws, oil lines and clamp. tighten cap screws to specifications. specification right-hand output gear assembly cap screws—torque . 27 n?m (20 lb-ft) 3. check output gear (b)-to-camshaft gear backlash. backlash must be as follows: specification output gear-to-camshaft gear— backlash 0.11—0.7 mm (0.004—0.028 in.) loctite is a registered trademark of loctite corp. dpsg,ouo1030,26 –19–15mar99–1/1 remove left-hand output gear assembly rg6899 –un–17aug93 a—oil line b—cap screw (3 used) 1. remove oil line (a)&output housing-to-idler housing cap screws (b). 2. remove housing&gear assembly from idler housing. discard gasket. ctm67 (24sep02) 53-5 oem engine acces***ies 092402 pn=333 auxiliary drive (8.1 l) 53 6 dpsg,ouo1030,27 –19–15mar99–1/2 disassemble left-hand output gear assembly rg6931 –un–23aug93 a—retaining collar b—bearing cone c—spacer ring d—oil restriction fitting e—bearing cone f—output gear 1. remove&inspect oil restriction orifice fitting (d). note: bearings will be damaged during disassembly and cannot be reused. 2. support gear side of housing in a press. 3. push on end of shaft to remove collar (a), bearing cone (b)&gear from housing. 4. remove other bearing cone (e) from gear (f). discard bearings&spacer ring (c). dpsg,ouo1030,27 –19–15mar99–2/2 rg6930 –un–23aug93 a—bearing cup b—snap ring c—bearing cup 5. evenly drive one bearing cup (a) out of housing bore. 6. remove snap ring (b)&press remaining bearing cup (c) out of housing bore. discard bearing cup and snap ring. ctm67 (24sep02) 53-6 oem engine acces***ies 092402 pn=334 auxiliary drive (8.1 l) 53 7 dpsg,ouo1030,28 –19–15mar99–1/2 assemble left-hand output gear assembly rg6932 –un–23aug93 a—bearing cup b—snap ring c—bearing cup important: bearings are damaged during disassembly. always install new bearings in a matched set. note: snap ring, spacer ring, bearing cups&bearing cones are provided in a matched set to maintain correct bearing clearance when assembled. 1. install snap ring (b) into housing groove. 2. press small id end of bearing cup (a) into gear end of housing bore until seated against snap ring. 3. support the first bearing cup. press small id end of second bearing cup (c) into opposite end of housing bore until firmly seated against snap ring. continued on next page ctm67 (24sep02) 53-7 oem engine acces***ies 092402 pn=335 auxiliary drive (8.1 l) 53 8 dpsg,ouo1030,28 –19–15mar99–2/2 rg6931 –un–23aug93 a—retaining collar b—bearing cone c—spacer ring d—oil restriction fitting e—bearing cone f—output gear important: roller bearing retainer can be easily damaged. do not press on retainer. press only on inner race of bearing cone. 4. press bearing cone (e) onto gear (f) so large end of cone is toward the gear. 5. install gear&bearing assembly into housing. install spacer ring (c) over shaft. 6. support gear&housing assembly on face of gear. press small end of second bearing cone (b) onto shaft until tight against spacer ring. 7. press collar (a) onto shaft (part number side facing outward) until seated solid against bearings. 8. check bearing clearance by rotating gear. gear must rotate freely. 9. using a new gasket, install oil restriction fitting (d) in housing. ctm67 (24sep02) 53-8 oem engine acces***ies 092402 pn=336 auxiliary drive (8.1 l) 53 9 dpsg,ouo1030,29 –19–15mar99–1/1 remove&install left-hand rear adapter housing rg6934 –un–23aug93 a—gasket b—housing 1. remove hex nuts&rear adapter housing (b). discard gasket (a). 2. using a new gasket, install rear adapter housing. tighten nuts to specifications. specification left-hand rear adapter housing-to-auxiliary drive housing nuts—torque 102 n?m (75 lb-ft) dpsg,ouo1030,30 –19–18mar99–1/3 remove idler housing&idler gear rg9505 –un–19mar99 a—timing cover cap screw (3 used) b—idler housing cap screw (4 used) c—large button head cap screw 1. remove vibration damper. (see engine repair manual.) note: upper timing gear cover cap screw (a) is also used to retain water pump. 2. loosen idler housing cap screws (b)&timing gear cover cap screws (a). 3. remove large button head cap screw (c). continued on next page ctm67 (24sep02) 53-9 oem engine acces***ies 092402 pn=337 auxiliary drive (8.1 l) 53 10 dpsg,ouo1030,30 –19–18mar99–2/3 rg6901 –un–05dec97 a—idler shaft 4. use do1209aa slide hammer&puller to pull idler shaft (a) loose from cylinder block. remove shaft and o-ring from housing. 5. remove idler housing cap screws&middle timing gear cover cap screw. note: face seal can be reused if not damaged. use care when removing idler housing from timing gear cover. 6. lift idler housing&gear out of timing gear cover opening. remove face seal&o-ring. dpsg,ouo1030,30 –19–18mar99–3/3 rg6904 –un–05dec97 a—cap screw b—housing bore 7. remove cap screw (a). slide idler gear out of housing. 8. remove o-ring from housing bore (b). ctm67 (24sep02) 53-10 oem engine acces***ies 092402 pn=338 auxiliary drive (8.1 l) 53 11 dpsg,ouo1030,31 –19–18mar99–1/1 replace idler gear bearing rg6928 –un–05dec97 a—outer bearing support b—idler bearing c—idler gear d—inner bearing support e—threaded hole 1. remove inner (d)&outer (a) bearing supports. 2. support gear&bearing assembly on face of gear. press on outer race of bearing (b) to remove bearing from gear (c). important: press only on outer race of bearing to avoid damaging bearing. 3. press bearing into gear until bearing is flush with face of gear. 4. install inner&outer bearing supports so idler shaft bores&cap screw holes align. note: inner idler bearing support has one threaded hole (e). dpsg,ouo1030,32 –19–18mar99–1/5 install idler housing&idler gear rg6904 –un–05dec97 a—cap screw with seal b—housing bore 1. grease&install o-ring in housing bore (b). note: inner idler bearing support with one threaded hole is installed toward block side of housing. 2. install idler gear into idler housing. install cap screw with seal (a) to hold idler gear in place. continued on next page ctm67 (24sep02) 53-11 oem engine acces***ies 092402 pn=339 auxiliary drive (8.1 l) 53 12 dpsg,ouo1030,32 –19–18mar99–2/5 rg6903 –un–05dec97 a—o-ring groove 3. insert idler shaft through idler housing&idler gear until flush with block side of housing. 4. grease o-ring groove (a) in back side of idler housing. insert o-ring. dpsg,ouo1030,32 –19–18mar99–3/5 rg6905 –un–05dec97 a—gauge hole note: face seal may be reused if it is not cut, nicked or damaged. 5. using a short guide stud, place face seal on timing gear cover opening. gauge hole (a) must be positioned toward bottom of opening. continued on next page ctm67 (24sep02) 53-12 oem engine acces***ies 092402 pn=340 auxiliary drive (8.1 l) 53 13 dpsg,ouo1030,32 –19–18mar99–4/5 rg6935 –un–08dec97 rg9505 –un–19mar99 a—timing gear cover cap screw (3 used) b—idler housing cap screw (4 used) c—large button head cap screw d—o-ring e—back-up ring important: be careful not to damage face seal or displace o-ring on back side of idler housing during assembly. 6. carefully insert idler gear into opening of timing gear cover until idler gear meshes with crankshaft gear and housing is seated against face seal. push idler shaft into block. 7. check condition of o-ring (d)&back-up ring (e) on large button head cap screw (c). grease o-ring and install cap screw through idler shaft. thread into block until finger tight. note: upper timing gear cover cap screw (a) is also used to retain water pump. note: middle timing gear cover cap screw must have a seal. 8. remove guide stud. install timing gear cover cap screws (a)&idler housing cap screws (b) finger tight. continued on next page ctm67 (24sep02) 53-13 oem engine acces***ies 092402 pn=341 auxiliary drive (8.1 l) 53 14 dpsg,ouo1030,32 –19–18mar99–5/5 rg9528 –un–24mar99 torque sequence 1,2—idler housing-to-timing gear cover 3—idler housing-to-cylinder block 4—idler housing-to-cylinder block 5—idler shaft 6,7,8—timing gear cover-to-cylinder block 9—idler housing-to-idler gear 9. tighten cap screws in the following sequence specification idler housing-to-timing gear cover (1,2)—torque 41 n?m (30 lb-ft) specification idler housing-to-cylinder block (3)—torque . 41 n?m (30 lb-ft) specification idler housing-to-cylinder block (4)—torque 102 n?m (75 (lb-ft) specification idler shaft (5)—torque . 150 n?m (110 lb-ft) specification timing gear cover-to-cylinder block (6,7,8)—torque . 27 n?m (20 lb-ft) specification idler housing-to-idler gear (9)— torque . 27 n?m (20 lb-ft) . 10. check idler gear-to-crankshaft gear backlash. specification idler gear-to-crankshaft gear— backlash 0.11—0.70 mm (0.004—0.028 in.) 11. if front drive is not used, install front cover and gasket. tighten cap screws to specifications. specification front cover cap screws—torque 41 n?m (30 lb-ft) 12. install vibration damper. (see engine repair manual.) ctm67 (24sep02) 53-14 oem engine acces***ies 092402 pn=342 auxiliary drive (8.1 l) 53 15 dpsg,ouo1030,33 –19–18mar99–1/1 install left-hand output gear assembly rg9507 –un–19mar99 a—oil supply line b—output housing cap screws c—spline teeth 1. install new gasket onto pilot of output housing. 2. insert output gear assembly into front opening of idler gear housing. tighten cap screws (b) to specifications. specification left-hand output gear housing cap screws—torque 41 n?m (30 lb-ft) 3. check output gear (c)-to-idler gear backlash. specification output gear-to-idler gear— backlash 0.08—0.74 mm (0.003—0.029 in.) 4. install oil supply line (a) on orifice fitting. ctm67 (24sep02) 53-15 oem engine acces***ies 092402 pn=343 auxiliary drive (8.1 l) 53 16 ctm67 (24sep02) 53-16 oem engine acces***ies 092402 pn=344 group 54 auxiliary drive (10.5 l&12.5 l) 54 1 dpsg,ouo1030,42 –19–19mar99–1/2 essential tools note: order tools according to information given in the u.s. servicegard? catalog/from the european microfiche tool catalog (mtc). servicegard is a trademark of deere & company dpsg,ouo1030,42 –19–19mar99–2/2 rg9040 –un–21may98 alignment tool jdg1144 align sae “a” front drive adapter. dpsg,ouo1030,41 –19–19mar99–1/1 auxiliary drive (10.5 l&12.5 l) specifications item measurement specification idler gear cap screw torque 220 n?m (162 lb-ft) sae “b” rear auxiliary drive torque 110 n?m (81 lb-ft) mounting cap screws sae “a” front adapter mounting torque 50 n?m (37 lb-ft) nuts sae “b” front drive adapter cap torque 55 n?m (40 lb-ft) screws ctm67 (24sep02) 54-1 oem engine acces***ies 092402 pn=345 auxiliary drive (10.5 l&12.5 l) 54 2 dpsg,ouo1030,34 –19–18mar99–1/1 remove&install auxiliary drive idler gear&bearing rg9508 –un–19mar99 a—cap screw b—support c—gear d—snap ring 1. remove damper, front plate&timing gear cover. (see engine repair manual.) 2. remove plug&o-ring from timing gear cover. 3. remove cap screw (a)&gear (c). 4. remove snap ring (d)&support (b) from gear (c). 5. install support (b) into gear (c)&install snap ring (d). 6. install gear (c)&cap screw (a). tighten to specifications. specification idler gear cap screw—torque 220 n?m (162 lb-ft) 7. install o-ring&plug in timing gear cover. 8. install timing gear cover, front plate&damper. (see engine repair manual.) ctm67 (24sep02) 54-2 oem engine acces***ies 092402 pn=346 auxiliary drive (10.5 l&12.5 l) 54 3 dpsg,ouo1030,35 –19–18mar99–1/3 remove&install sae “a”&“b” front&sae “b” rear auxiliary drive assembly rg9516 –un–17mar99 auxiliary drive assembly a—cover plate e—snap ring h—o-ring k—“b” front adapter b—gasket f—bearing i—“a” front adapter l—gasket c—“b” rear adapter housing g—splined gear j—o-ring m—cover plate d—o-ring 1. remove cover plate (m). 2. remove sae “b” front adapter (k). discard o-ring (j). 3. remove sae “a” front adapter (i) from timing gear cover. discard o-ring (h). 4. remove cover plate (a). 5. remove sae “b” rear auxiliary drive assembly (c) from front plate. discard o-ring (d). 6. support front face of adapter housing (c). press gear (g)&bearing (f) out of housing bore. 7. remove snap ring (e) from gear shaft. discard snap ring. 8. remove bearing from gear. discard bearing. 9. thoroughly clean&inspect gear&housing. 10. assemble new bearing (f) onto gear shaft (g). ctm67 (24sep02) 54-3 oem engine acces***ies 092402 pn=347 continued on next page auxiliary drive (10.5 l&12.5 l) 54 4 dpsg,ouo1030,35 –19–18mar99–2/3 11. determine correct snap ring to achieve 0.11 mm (0.004 in.) maximum clearance between bearing cone&snap ring&install new snap ring (e). 12. support back side of adapter housing. press gear and bearing assembly into housing until assembly bottoms. 13. install new o-ring (d)&sae “b” rear auxiliary drive adapter (c) onto front plate using a new gasket. tighten cap screws to specifications. specification sae “b” rear auxiliary drive mounting cap screws—torque . 110 n?m (81 lb-ft) 14. install gasket&cover plate (a). dpsg,ouo1030,35 –19–18mar99–3/3 rg9036 –un–25mar99 a—sae “a” front adapter b—nut (4 used) c—jdg1144 alignment tool important: front auxiliary drive adapter (a) must be properly aligned with center of gear spline whenever front/rear adapter(s) are removed. improperly aligned

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska