详细描述

麦克福斯约翰迪尔发动机零配件

约翰迪尔 6081 高压缩活塞

|

| |||||||||||||||||||||||||||

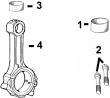

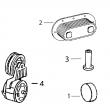

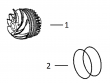

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

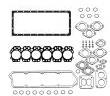

(3)纸垫片。

(4)金属/橡胶垫圈。

(5)套件中均包含前部密封件。

(6)检查应用程序是否正确使用。

美国强鹿JOHN DEERE柴油发电机配件及发动机配件:

CD3029DF128、CD4039DF008、CD4045TF258、PE4045、CD6068TF158、CD6068TF258、CD6068HF158、CD6068HF258、CD6081HF001A、4045TFM75、CD6081HF001B、CD6125HF070A、CD6125HF070B、RG6125、6135H458。4045DFM70, 4045TFM75, 6068TFM75, 6068TFM76、4039DFM RE522528、RE519774、RE532628、RE518176、RE507980、RE518503、RE522515、RE504836、RE509031/

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE509032、RE59754、RE507284、RE59754、RE519626、RE508202、RE58935、T19044、RE62418、RE62419、RE521248、RE520842、C085004、RE509672、RE196945、RE191915、RE522688、RE522687、RE519774、RE532628、RE507980、RE531703、RE24619ar85419 power-takeoff 1 (side load) (fi) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9700-9719 pn=609 p r o o f p r o o f field installed kits 9701 air filter, heavy duty 9701 filtre a air 9701 luftfilter 9701 depuratore d’aria 9701 filtro de aire 9701 luftrenare rgp4761 -un-12sep96 this parts listing is continued 9700-9720 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=610 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 re16811 cap 1 (a) (b) (c) 2 at66469 clamp 1 (a) (b) (c) (includes re28139) 3 re16810 band 2 (a) (b) (c) 4 19h3704 cap screw 2 (a) (b) (c) 3/8" x 2-1/4" 5 re16807 air cleaner 1 (a) (b) (c) 6 r56902 label 1 (a) (b) (c) 7 r45096 valve 1 (a) (b) (c) 8 re16809 filter element 1 (a) (b) (c) 9 e52884 nut 1 (a) (b) (c) 10 e52882 pin fastener 1 (a) (b) (c) 11 at69791 nut 1 (a) (b) (c) 12 e52880 gasket 1 (a) (b) (c) 13 p46402 snap ring 1 (a) (b) (c) 14 re16808 filter element 1 (a) (b) (c) 15 a21066 bushing 1 (a) (b) (c) 16 r119758 strap 1 (a) (b) (c) 17 19h3169 cap screw 1 (a) (b) (c) 5/8" x 4-1/4" 18 19h2021 cap screw 1 (a) (b) (c) 3/8" x 5/8" 19 19h2284 cap screw 4 (a) (b) (c) 3/8" x 7/8" 20 24h1305 washer 4 (a) (b) (c) 13/32" x 13/16" x 0.065" 21 19h2284 cap screw 1 (a) (b) (c) 3/8" x 7/8" 22 re64310 support 1 (a) (b) (c) re54109 support 1 (a) (b) (c) (4 psi) 23 t13814 clamp 1 (a) (b) (c) 24 24h1287 washer 1 (a) (b) (c) 9/32" x 5/8" x 0.065" 25 19h1919 cap screw 1 (a) (b) (c) 1/4" x 5/8" 26 n131096 bushing 1 (a) (b) (c) 27 19h1833 cap screw 1 (a) (b) (c) 5/8" x 1-1/4" 28 e55662 flange nut 4 (a) (b) (c) 29 turbocharger 1 (a) (b) (c) 30 re52703 hose clamp 1 (a) (b) (c) 31 r97097 hose 1 (a) (b) (c) 32 re67747 clamp 2 (a) (b) (c) 33 r128864 tube 1 (a) r128865 tube 1 (b) r133131 tube 1 (c) 34 r128866 suction hose 2 (a) (b) (c) 35 at66469 clamp 1 (a) (b) (c) rg24871 kit 1 (consists of (2) re16807) (a) rear exhaust - low profile - dual stage - heavy duty echappement arriere - a basse section - deux etages - usage intensif hinterer auspuff - niedriges profil - zweistufig - verstaerkte ausfuehrung scarico posteriore - montaggio basso - doppio stadio - per servizio pesante tubo de escape trasero - bajo perfil - dos etapas - servicio severo bakre avgas - laag profil - tvaa etapper - extra kraftig (b) front exhaust - high mount - dual stage - heavy duty (opposite as shown) echappement avant - montage haut - deux etages - usage intensif (non represente) vorderer auspuff - hohe montage - zweistufig - verstaerkte ausfuehrung (gegenteil des abgebild) scarico anteriore - montaggio alto - doppio stadio - per servizio pesante (non in figura) tubo de escape delantero - montaje alto - dos etapas - servicio severo (opuesto al ilustrado) fraemre avgas - hoeg montering - tvaa etapper - extra kraftig (motsatt den visade) (c) front exhaust - lo-turbo - dual stage - heavy duty (not as shown) echappement avant - suralimente bas - deux etages - usage intensif (non represente) vorderer auspuff - niedrig-turbo - zweistufig - verstaerkte ausfuehrung (nicht wie abgebildet) scarico anteriore - turbocompressione bassa - doppio stadio - per servizio pesante (non in figura) tubo de escape delantero - baja turbocompresion - dos etapas - servicio severo (difiere de la i fraemre avgas - laag turbo - tvaa etapper - extra kraftig (ej som visad) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9700-9721 pn=611 p r o o f p r o o f field installed kits 9701 air cleaner parts for field installation 9701 pieces de filtre a air a installer sur le terrain 9701 luftfilterteile fuer nachruestung 9701 componenti filtro dell’aria per installazione sul campo 9701 piezas del filtro de aire para instalaction en campo 9700 lusftfilterdelar foer installation paa platsen rgp7999 -un-15aug01 this parts listing is continued 9700-9722 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=612 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 15h558 pipe plug 1 1/8" 2 r133585 elbow fitting 1 3 r133586 reducer 1 (front) 4 r133588 tube 1 (front) 5 r133587 tube 1 (rear) 6 r128254 suction hose 1 (rear) 7 r56902 label 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9700-9723 pn=613 p r o o f p r o o f field installed kits 9701 instrument panel kit 9701 kit tableau de bord 9701 instrumententafelsatz 9701 kit cruscotto 9701 juego tabelero de instrumentos 9701 instrumentbraedasats rgp7994 -un-15aug01 engine key part no. part name qty serial no. remarks 1 re162450 wiring harness 1 2 re162418 pressure gauge 1 3 re68155 gauge 1 4 ae21116 fuse holder 1 at28061 fuse 1 (5 amp) 5 ar58126 key switch 1 a4827r washer 1 r44342 nut 1 l38138 receptacle connector body 1 6 re163465 switch 1 7 re162419 tachometer 1 8 re162416 temp, erature gauge 1 9 re503681 wiring harness 1 10 r78066 pin contact 15 (includes ar51481) 11 r78068 pin contact 4 12 r78069 electrical plug 1 13 u46662 terminal 2 14 57m7498 socket contact 3 15 57m7748 receptacle 1 16 re508625 instrument panel 1 9700-9724 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=614 p r o o f p r o o f field installed kits 9701 fuel line adaptive fittings kit 9701 raccords adaptateurs de conduite de carburant 9701 anpassungsverschraubungen fuer kraftstoffleitung 9701 raccordi adattativi per tubi d’alimentazione 9701 adaptadores para linea de combustible 9701 anpassningsfoerskruvningar foer braensleledning rgp5414 -un-15sep99 engine key part no. part name qty serial no. remarks 1 re502954 elbow fitting 1 2 t77613 o-ring 1 3 re504781 fuel line 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9700-9725 pn=615 p r o o f p r o o f field installed kits 9701 list of individual parts for a/c compres*** denso/sanden 9701 monture de compresseur (denso/sanden) 9701 kompres***befestigung (denso/sanden) 9701 montante compres***e (denso/sanden) 9701 montaje del compre*** (denso/sanden) 9701 kompres***faeste (denso/sanden) rgp7996 -un-15aug01 this parts listing is continued 9700-9726 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=616 p r o o f p r o o f field installed kits engine key part no. part name qty serial no. remarks 1 14m7296 flange nut 2 m10 2 14m7298 flange nut 3 3 ty24304 compres*** 1 (a) (denso) re68372 compres*** 1 sanden 4 19m7913 screw 3 m8 x 90, (use with ty24304) 19m7970 screw 3 m8 x 100, (use with re68372) 5 34m7189 spring pin 2 11 x 8 mm, (use with ty24304) 6 r128802 bracket 1 (use with ty24304/re68372) (front) 7 19m7898 screw 2 m10 x 130 8 r500320 spacer 1 9 re505265 idler 1 10 r107749 sleeve 1 -xxxxxx r502079 sleeve 1 xxxxxx- 11 19m7807 screw 1 m10 x 60 12 r128858 bracket 1 (use with ty24301) (rear) r500063 bracket 1 (use with re68372) (rear) remanufactured rechange standard generaueburholt rigatto refabricado por renoverad powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9700-9727 pn=617 p r o o f p r o o f field installed kits main repto housing (sae 1) (w/o aux pump) yz2140 -un-19jun02 transmission key part no. part name qty serial no. remarks 1 f85005 fitting plug 2 2 19h1227 cap screw 2 3 yz101113 cover 1 4 yz250086 tag 1 5 f310063 screw 2 6 yz110040 housing 1 sae no. 1 7 yz104308 cover 1 8 19m6810 cap screw 4 8x18mm, hex 9 f85012 fitting plug 1 10 f2710616 dowel pin 2 11 r53955 o-ring 1 12 f85003 fitting plug 1 13 yz104317 cover 1 14 19m7843 screw 4 9700-9728 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=618 p r o o f p r o o f field installed kits main repto housing (sae 1) (w/ aux pump) yz2140a -un-21jun02 transmission key part no. part name qty serial no. remarks 1 f85005 fitting plug 2 (contains r26286) 2 19h1227 cap screw 2 3 yz101113 cover 1 4 yz250086 tag 1 5 f310063 screw 2 6 yz110040 housing 1 sae no. 1 7 yz104308 cover 1 8 19m6810 cap screw 4 8x18mm, hex 9 f85012 fitting plug 1 10 f2710616 dowel pin 2 11 r53955 o-ring 1 12 f85003 fitting plug 2 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9729 pn=619 p r o o f p r o o f field installed kits primary pump yz2134 -un-13mar02 transmission key part no. part name qty serial no. remarks 1 yz250022 bearing 2 2 yz104301 gear 1 40t 3 t80622 o-ring 1 4 yz110030 cover 1 sae c 5 19h3158 cap screw 4 9700-9730 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=620 p r o o f p r o o f field installed kits primary idler shaft yz2135 -un-13mar02 transmission key part no. part name qty serial no. remarks 1 yz104328 cylindrical roller bearing 2 2 f39000334 snap ring 1 3 yz104302 gear 1 52t 4 yz110042 shaft 1 5 n208934 o-ring 1 6 yz104379 plate 1 7 19m6810 cap screw 2 8x18mm, hex orifice plug in idler shaft is 4004247b. powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9731 pn=621 p r o o f p r o o f field installed kits auxiliary pump yz2137 -un-13mar02 transmission key part no. part name qty serial no. remarks 1 f85005 fitting plug 1 2 f85003 fitting plug 2 3 19m7845 screw 4 4 yz110041 housing 1 5 yz250022 bearing 2 6 yz104301 gear 1 40t 7 t80622 o-ring 1 8 yz110030 cover 1 sae c 9 19h3158 cap screw 4 9700-9732 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=622 p r o o f p r o o f field installed kits auxiliary idler shaft yz2136 -un-09apr02 transmission key part no. part name qty serial no. remarks 1 yz104329 cylindrical roller bearing 2 2 f39000315 snap ring 1 3 yz104318 gear 1 40t 4 yz110043 shaft 1 5 n208934 o-ring 1 6 yz104379 plate 1 7 19m6810 cap screw 2 8x18mm, hex orifice plug in idler shaft is 4004247b. powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9733 pn=623 p r o o f p r o o f field installed kits input gear yz2138 -un-13mar02 transmission key part no. part name qty serial no. remarks 1 t76054 o-ring 1 2 yz110021 gear 1 52t 3 f21042sc cap 1 9700-9734 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=624 p r o o f p r o o f field installed kits seal retainer yz2139 -un-13mar02 transmission key part no. part name qty serial no. remarks 1 f37030276g o-ring 1 2 yz110029 bearing 1 3 yz110044 retainer 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9735 pn=625 p r o o f p r o o f field installed kits sae ’b’ adapter rgp9248 -un-20nov02 transmission key part no. part name qty serial no. remarks 1 t76054 o-ring 1 2 yz102370 adapter 1 sae b 3 f37030242g o-ring 1 4 yz104332 sleeve 1 5 19h3579 cap screw 4 6 yz104335 adapter 1 9700-9736 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=626 p r o o f p r o o f field installed kits sae ’bb’ adapter rgp9248 -un-20nov02 transmission key part no. part name qty serial no. remarks 1 t76054 o-ring 1 2 yz102370 adapter 1 sae bb 3 f37030242g o-ring 1 4 yz104333 sleeve 1 5 19h3579 cap screw 4 6 yz104336 adapter 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9737 pn=627 p r o o f p r o o f field installed kits sae ’c’ adapter kit rgp9249 -un-20nov02 transmission key part no. part name qty serial no. remarks 1 t76054 o-ring 1 2 4028145 sleeve 1 3 yz104337 kit 1 9700-9738 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=628 p r o o f p r o o f field installed kits sae ’d’ adapter yz2015 -un-20jun02 transmission key part no. part name qty serial no. remarks 1 t80622 o-ring 1 2 yz110035 adapter 1 sae d 3 yz104383 stud 4 4 f13015000 nut 4 5 f37030258g o-ring 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9700-9739 pn=629 p r o o f p r o o f field installed kits drive flange assembly rgp9250 -un-20nov02 transmission key part no. part name qty serial no. remarks 1 4028020 adapter 1 2 4028070 shaft 1 3 f40211 ball bearing 1 4 f65013 seal 1 5 f39000393 snap ring 1 6 f39010215 snap ring 1 7 f370302586 o-ring 1 9700-9740 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=630 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning rgp8069 -un-15aug01 9900 - 9900 - 9901 - 9901 - 9901 - 9901 - 9901 - 9901 - powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9900-a01 pn=631 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits sectional index index de section gruppenindex indice della sezione indice de seccion gruppsforteckning 9900 - 9900 - 9901 - 9901 - 9901 - 9901 - 9901 - 9901 - 9900-a02 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=632 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 belt (12 rib) 9901 courroie, 12 nervures 9901 rieman, 12 rippon 9901 cinghia, 12 costole 9901 correa, 12 nervaduras 9901 rem, 12 ribbor rgp6865 -un-10aug00 engine key part no. part name qty serial no. remarks 1 r502306 v-belt 1 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) 9900-9901 pn=633 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 engine short block with head bolts 9901 monteur depouille pour rechange (avec (26) boulons de culasse) 9901 kurzmotor (mit (26) zylinderkopfschrauben) 9901 motore corto (con (26) viti della testata) 9901 motor basico (con (26) pernos de cabeza) 9901 kortmotor (med (26) topplocksskruvar) rgp4978 -un-29jan98 this parts listing is continued 9900-9902 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=634 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 re508141 short block assembly 1 (marked r502884) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9900-9903 pn=635 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 engine overhaul kits 9901 bloc-cylavec equip.mobile 9901 rumpfmotor 9901 monoblocco preassemblato 9901 bloque de cilcon piez.mov. 9901 kotblock rgp5134 -un-28jan99 this parts listing is continued 9900-9904 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=636 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 rg31337 engine overhaul kit 1 (marked r502884) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9900-9905 pn=637 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 bearings&washers 9901 piece d’ecartement et roulements 9901 distanzstuecke und lager 9901 distanziatore e cuscinetti 9901 espaciator y cojinetes 9901 distansstycke och lager rgp4715 -un-07aug96 engine key part no. part name qty serial no. remarks 1 re63906 thrust washer 1 std (pkg (3) r116299) re68659 thrust washer 1 0.18 mm (.007") os flange (pkg (2) r133599 &r116299) (6105/6125-code 4701) 2 re63905 thrust bearing 1 std size (pkg r129751&r129752) re68663 thrust bearing 1 0.25 mm (.010") us (pkg r133606&r133607) re68664 thrust bearing 1 0.50 mm (.020") us (pkg r133608&r133609) 3 re63903 bearing ar std size (pkg r129749&r129750) re68655 bearing ar 0.25 mm (.010") us (pkg r133600&r133601) re68656 bearing ar 0.50 mm (.020") us (pkg r133602&r133603) 9900-9906 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=638 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 camshaft&pin kit 9901 kit d’arbre a cames et d’axe 9901 nockenwelle und stiftsatz 9901 albero a camme e kit perni 9901 juego de arbol de levas y pasadores 9901 sata med kamaxel och sprint rgp5416 -un-15sep99 engine key part no. part name qty serial no. remarks 1 r117020 pin 1 2 re506962 kit 1 (marked r503970) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) 9900-9907 pn=639 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 engine gasket sets 9901 jue de joints moteur 9901 motor-dichtungssatz 9901 serie guarnizioni motore 9901 juego de juntas para el motor 9901 packningssats for motor rgp7074 -un-05dec00 this parts listing is continued 9900-9908 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=640 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 r72328 o-ring 2 2 r63185 o-ring 1 3 r130738 gasket 1 4 r56461 o-ring 1 5 r133651 packing 6 6 r502703 packing 6 (sub for r133652) r133653 packing 6 7 r130772 packing 6 8 r26375 o-ring 3 9 t77613 o-ring 7 10 t77857 o-ring 1 11 51m7045 o-ring 1 19.300 x 2.200 mm 12 r116830 gasket 1 13 51m7041 o-ring 1 11.300 x 2.200 mm 14 r26448 o-ring 6 15 re57784 engine cylinder head gasket 1 16 r500211 gasket 1 17 r62976 o-ring 1 18 r500212 gasket 1 (also order n102039) 19 t70176 ring 1 r82459 o-ring 1 t74492 o-ring 1 20 r502026 v-ring seal 1 21 r502441 v-ring seal 1 22 r500387 gasket 1 (sub for r120741) 23 r56757 o-ring 1 24 e52687 o-ring 1 25 r56751 o-ring 4 26 r29936 o-ring 1 27 r116494 gasket 1 28 r126783 gasket 1 29 r63548 o-ring 12 30 u17409 o-ring 3 31 r500210 gasket 1 32 r500209 gasket 1 33 r134716 o-ring 2 34 r35043 gasket 1 35 r56464 o-ring 1 36 r133142 gasket 1 37 r116205 gasket 1 38 r105346 gasket 1 39 r49697 gasket 1 40 r131809 gasket 6 41 r500318 o-ring 1 42 t35580 o-ring 1 43 r119148 gasket 1 44 r502027 spider 1 45 re507241 gasket kit 1 (a) (sub for rg30988) (cylinder head) 46 re507243 kit 1 (b) (sub for rg30989) (engine rebuild) n102039 cap 4 re501468 o-ring kit 1 (sub r56461, (6) r133651, (6) r133652, (6) r133653&t35580) (injection nozzel) cylinder head engine gasket set culasse jue de joints moteur zylinderkopf motor-dichtungssatz testata serie guarnizioni motore culata juego de juntas para el motor cylindertopp packningssats for motor powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-aug-01) 9900-9909 pn=641 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 lift straps 9901 eclisses d’apareil de levage 9901 hubstrebe 9901 fascette del paranco 9901 tiras de elevador 9901 motorlyftsfaesten rgp4669 -un-10aug96 engine key part no. part name qty serial no. remarks 1 r128000 strap 1 (rear) r128001 strap 1 (not shown) 2 19m7789 screw 2 9900-9910 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=642 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 9901 9901 9901 9901 9901 rgp5408 -un-15sep99 engine key part no. part name qty serial no. remarks 1 t146102 label 1 (a) 2 re41759 shield 1 3 t146106 safety sign 1 (d) t146104 safety sign 1 (e) t146515 safety sign 1 (f) t146516 safety sign 1 (g) t146517 safety sign 1 (h) (a) english (b) spanish english espanol english espanol english spanish english espanol english espanol (c) french (d) german francais deutsch francais deutsch francais deutsch francais deutsch francais deutsch (e) italian (f) english/french italiano english/francais italiano english/francais italiano english/francais italiano english/francais italiano english/francais powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9900-9911 pn=643 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 torq-gard supreme&plus-50 engine oil 9901 huile moteur torq-gard oil 9901 torq-gard plus 50 motoroel 9901 olio motore torq-gard plus 50 9901 aceite de motro torq-gard plus 50 9901 gard plus 50 motorolja rgp3291 -un-01jan94 engine key part no. part name qty serial no. remarks 1 ty22064 torq-gard supreme 1 (sae 5w/30), 0.9l (1 qt) ty22065 torq-gard supreme 1 (sae 5w/30), 19l (5 gal) ty22066 torq-gard supreme 1 (sae 5w/30), 208l (55 gal) ty6364 oil 1 (sae 10w/30), 0.9l (1 qt) (breakin) ty22067 torq-gard supreme 1 (sae 10w), .9l (1 gal) ty22068 torq-gard supreme 1 (sae 10w), 19l (5 gal) ty22069 torq-gard supreme 1 (sae 10w), 208l (55 gal) ty22070 torq-gard supreme 1 (sae 30w), 0.9l (1 gal) ty22073 torq-gard supreme 1 (sae 30w), 19l (5 gal) ty6280 oil 1 (sae 30w), 114l (30 gal) ty22074 torq-gard supreme 1 (sae 30w), 208l (55 gal) 2 ty6389 torq-gard supreme plus-50 1 (sae 15w/40), 0.9 l (1 qt) ty22008 torq-gard supreme plus-50 1 (sae 15w/40), 3.8 l (1 gal) ty6390 torq-gard supreme plus-50 1 (sae 15w/40), 19 l (5 gal) ty22010 torq-gard supreme plus-50 1 (sae 15w/40), 113.6 l (30 gal) ty6391 torq-gard supreme plus-50 1 (sae 15w/40), 208 l (55 gal) ty6392 oil 1 (sae 30w), 0.9 l (1 qt) ty22007 oil 1 (sae 30w), 3.8 l (1 gal) ty6393 oil 1 (sae 30w), 19 l (5 gal) ty22011 oil 1 (sae 30w), 113.6 l (30 gal) ty6394 oil 1 (sae 30w), 208 l (55 gal) ty22041 engine break-in oil 1 (sae 10w/30), 3.8 l (1 gal) (breakin) ty22042 engine break-in oil 1 (sae 10w/30), 208 l (55 gal) (breakin) 9900-9912 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=644 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits memoranda memoranda memoranda memoranda memoranda memoranda powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9900-9913 pn=645 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 acces***y parts 9901 accessoires 9901 zubehoerteile 9901 acces***i 9901 acce***ios 9901 tillbehor rgp4314 -un-01jan94 this parts listing is continued 9900-9914 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=646 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 ar44402 oil 1 0.9 l (1 qt.) 2 ty16004 engine coolant conditioner 1 3 ty16005 engine coolant conditioner 1 (not as shown) 4 ar54749 lubricant 1 0.9 l (1 qt.) at66865 lubricant 1 (electrical connections) (not shown) ty24311 sealant 1 (use with rg27867) ar41785 kit 1 (contains 0.9 l (1 qt) (off-season storage) ar21969 kit 1 (dustcap/cover kit) ds0251 kit 1 (coolant scan test) ipskit1 kit 1 (oil scan test) ds0557 valve 1 (sampling system) ty16423 level gauge 1 (coolant eye - fill/flushing port) ty16034 antifreeze 1 (1 gal.) (concentrate) ty16035 antifreeze 1 (55 gal) (concentrate) ty16036 antifreeze 1 (2 1/2 gal. container) (pre-mix) ty16037 antifreeze 1 (55 gal. container) (pre-mix) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9900-9915 pn=647 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 weather pac terminals 9901 9901 9901 9901 9901 rwp3850 -un-01jan94 this parts listing is continued 9900-9916 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=648 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 r78063 terminal nipple 1 (d) (e) r78059 electrical plug 1 (d) (f) r78062 terminal nipple 1 (d) (g) 2 r78057 socket contact 1 (d) (h) r78060 socket contact 1 (d) (i) 3 r78047 seal 1 (c) 4 re12362 connector 1 (b) 5 r78052 pin contact connector body 1 (b) 6 r78061 pin contact 1 (d) (i) 7 r78063 terminal nipple 1 (d) (e) 8 re12334 connector 1 9 r78060 socket contact 1 (d) (i) 10 r78048 terminal nipple 1 (c) 11 re12363 connector 1 (b) 12 re12331 connector 1 13 r78053 pin contact connector body 1 (b) 14 re12330 connector 1 15 r78049 seal 1 (c) 16 re12364 socket cont.connector body 1 (b) 17 r78054 pin contact connector body 1 (b) 18 re12332 connector 1 19 r78050 seal 1 (c) 20 re12365 connector 1 (a) 21 re12333 connector 1 22 r78055 pin contact connector body 1 (a) 23 r78061 pin contact 1 (d) (i) r78058 pin contact 1 (d) (h) 24 r78051 seal 1 (c) 25 re12366 connector 1 (a) 26 r78056 pin contact connector body 1 (a) 27 r78064 electrical plug 1 (d) (a) pkg of 2 (b) pkg of 3 par paquet de 2 par paquet de 3 verpackt zu 2 verpackt zu 3 in confezione da 2 in confezione da 3 por paquete de 2 por paquete de 3 i sats eller paket 2 i sats eller paket 3 (c) pkg of 5 (d) pkg of 40 par paquet de 5 par paquet de 40 verpackt zu 5 verpackt zu 40 in confezione da 5 in confezione da 40 por paquete de 5 por paquete de 40 i sats eller paket 5 i sats eller paket 40 (e) 16 ga. wire (gray) (f) 18/20 ga. wire (green) 16 ga. fil (gray) 18/20 ga. (vert) 16 ga. daht (gray) 18/20 ga. daht (gruen) 16 ga. filo metallico (gray) 18/20 ga. filo metallico (verde) 16 ga. alambre (gray) 18/20 ga. alambre (verde) 16 ga. vajer (gray) 18/20 ga. (groen) (g) 14 ga. wire (blue) (h) 18/20 ga. wire (no. 19) 14 ga. fil (bleu) 18/20 ga. fil (no. 19) 14 ga. daht (blau) 18/20 ga. daht (no. 19) 14 ga. filo metallico (blu) 18/20 ga. filo metallico (no. 19) 14 ga. alambre (azul) 18/20 ga. alambre (no. 19) 14 ga. vajer (blaa) 18/20 ga. vajr (no. 19) (i) 14/16 ga. wire (no. 15) 14/16 ga. fil (no. 15) 14/16 ga. daht (no. 15) 14/16 ga. filo metallico (no. 15) 14/16 ga. alambra (no. 15) 14/16 ga. vajer (no. 15) powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (22-dec-00) 9900-9917 pn=649 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits 9901 metri-pack terminals&connectors 9901 cosses et connecteurs metri-pack 9901 metri-packanschlusse und verbinder 9901 morsetti metri-pack e collegamenti elettrici 9901 terminales y conectores metri-pack 9901 metri-pack anslutningsdon och kontakter rxp011000 -un-01jan94 this parts listing is continued 9900-9918 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (09-jan-02) pn=650 p r o o f p r o o f engine short block, gasket sets, lubricants&oil scan kits engine key part no. part name qty serial no. remarks 1 57m7315 connector 1 2 57m7258 elect. connector acces***y ar 3 r104846 socket contact ar 16 ga. 4 57m7266 receptacle 泉州洛江帕金斯1006柴油发动机的价格去哪买?,焦作孟州CAT装载机297C配件欢迎咨询?,云浮郁南县康明斯柴油机动力系统维修的地方在那?,大连沙河口CAT3406柴油机配件修理包8C4452规格型号及价格查询?,咸阳旬邑县Perkins发动机后油封多少钱一套?,潍坊高密德国奔驰mtu配件网点,北京昌平珀金斯缸盖ZZ80262批发,博尔塔拉精河县CAT3034发动机配件原装正品,pn=76 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 9 rg,rg34710,1074 –19–23oct97–1/2 head gasket inspection&repair sequence serial number ( —199,999) rg6448 –un–26nov97 inspecting cylinder head gasket a—combustion seals (flange) c—rocker arm oil port d—elastomer beading strips e—front of engine b—gasket body the following inspection procedures are recommended whenever a head gasket joint failure occurs,/when joint disassembly takes place. 1. review historical data relating to machine operation, maintenance&repair, along with diagnostic observations. note all areas requiring further inspection&analysis. 2. remove rocker arm cover&check for presence of coolant in the oil. 3. record head cap screw torques prior to removal. upon removal, check cap screw length differences. 4. remove cylinder head using appropriate lifting devices to prevent handling damage to head gasket. see remove cylinder head serial number ( —199,999) in group 020. 5. observe surfaces of removed head gasket. examine combustion seals (a) for the following: ? flange severed/expanded/cracked/deformed. ? adjacent body area burned/eroded. ? fire ring severed/displaced/missing. ? flange sealing pattern eccentric/contains voids. ? discoloration of flange&adjacent body areas. ? flange surfaces rough/abraded/channelled. examine gasket body (b) for the following: ? combustion gas erosion paths/soot deposits originating at combustion seals. ? extreme discoloration/hardening/embrittlement in localized areas. ? o-ring seal missing/damaged in port area (c). ? elastomer missing/damaged in port area (d). ? oil/coolant paths from port areas. ? localized areas of low compression. 6. before cleaning components, inspect head, block, and liners for evidence of combustion gas&fluid leakage. inspect cylinders&valve ports for unusual deposits. 7. clean block, head, liners,&cap screws. (groups 020&030.) ctm86 (20mar01) 02-020-9 powertech? 8.1 l diesel engines — base engine 032001 pn=77 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 10 rg,rg34710,1074 –19–23oct97–2/2 8. proceed with the following dimensional checks and visual inspections: cylinder head (group 020.) ? check surface flatness/finish. ? inspect for surface damage. ? check cylinder head thickness, if resurfacing. cylinder block&liners (assembled and clamped) (group 020/030.) ? check liner standout at four places on each liner. ? check liner standout difference between cylinders. cylinder block (group 030.) ? check surface flatness/finish. ? inspect for surface damage. ? check liner counterbore depth (if liner is removed). ? check top deck to crankshaft centerline dimension. ? inspect cap screw bosses, must be clean/intact. cylinder liner (group 030.) ? check liner flange flatness/finish. ? check liner flange thickness (if liner is removed). ? inspect flange for damage. cylinder head cap screws (group 020.) ? inspect for corrosion damage. ? inspect condition of threads. ? inspect for straightness. ? check length. 9. when inspections&measurements have been completed, determine most probable causes of joint failure. make all necessary repairs to joint components, cooling system,&fuel injection system. 10. reassemble the engine according to procedures and specifications in the repair groups of this manual. ctm86 (20mar01) 02-020-10 powertech? 8.1 l diesel engines — base engine 032001 pn=78 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 11 rg,rg34710,1075 –19–23oct97–1/3 disassemble&inspect rocker arm shaft assembly serial number ( —199,999) rg3801 –un–04dec97 rocker arm shaft assembly a—plugs b—washers note: make preliminary inspection during disassembly. look for: —worn/scored rocker arms, shaft,&shaft support. —weak/broken springs —lube oil restriction 1. remove plugs (a)&washers (b) from ends of rocker arm shaft. 2. slide springs, rocker arms,&rocker arm supports off rocker arm shaft identifying their parts for reassembly in the same sequence they were in before disassembly. rg,rg34710,1075 –19–23oct97–2/3 rg3802 –un–04dec97 rocker arm parts a—rocker arm shaft b—screw c—rocker arm adjusting nut 3. inspect rocker arm shaft (a) for severe scratching, scoring,/excessive wear at points of rocker arm contact. measure rocker arm&shaft. compare with, specifications given below. specification rocker arm assembly—i.d. 19.07—19.10 mm (0.7507—0.7520 in.) shaft o.d. 19.01—19.05 mm (0.7484—0.7500 in.) note: wear could indicate weak valve springs, bent push rods,/loose rocker arm shaft clamps. 4. check rocker arm adjusting nut (c)&screw (b) for damage. visually inspect rocker arm for hairline cracks. replace if necessary. important: be sure all oil holes in rocker arm shaft are clean&open. 5. clean all rocker arm parts with clean solvent. dry with compressed air. ctm86 (20mar01) 02-020-11 powertech? 8.1 l diesel engines — base engine 032001 pn=79 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 12 rg,rg34710,1075 –19–23oct97–3/3 rgr26131 –un–12jan98 rocker arm wear area a—wear area 6. check for cups/concave wear (a) on ends of rocker arms where they contact wear caps. 7. examine spacer springs on shaft between rocker arms. be sure they are strong enough to exert a positive pressure on rocker arms. note: if the rocker arm has been damaged by a valve failure, replace it&the push rods when replacing valves. 8. roll rocker arm shaft&push rods on a flat surface to check for bends/distortion. replace parts as necessary. rg,rg34710,1076 –19–23oct97–1/1 assemble rocker arm shaft assembly serial number ( —199,999) rg3801 –un–04dec97 rocker arm shaft assembly a—rocker arm shaft end plugs b—washers assemble parts on rocker arm shaft in reverse of removal procedure. make sure rocker arm shaft end plugs (a) are firmly seated against end of shaft,&washers (b) are installed on shaft. ctm86 (20mar01) 02-020-12 powertech? 8.1 l diesel engines — base engine 032001 pn=80 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 13 rg,rg34710,1077 –19–27apr99–1/1 measure valve recess serial number ( —199,999) rg5250 –un–07nov97 measuring valve recess measure&record valve recess dimensions for all valves using jdg451 gauge with d17526ci (english, in.) or d17527ci (metric, mm) dial indicator/kjd10123 gauge. compare measurements to specifications given below. specification exhaust valve—recess 1.19—1.70 mm (0.047—0.067 in.) below cylinder head maximum recess 2.46 mm (0.097 in.) below cylinder head . intake valve—recess 3.35—3.86 mm (0.132—0.152 in.) below cylinder head . maximum recess 4.62 mm (0.182 in.) below cylinder head . note: thoroughly clean all gasket material from cylinder head combustion face before measuring. if measurement does not meet specifications, check valve face angle&valve seat angle. if valve is recessed beyond the maximum specification, install either new valves, valve seat inserts,/both to obtain proper valve recess. see remove valve seat inserts serial number ( —199,999) later in this group. ctm86 (20mar01) 02-020-13 powertech? 8.1 l diesel engines — base engine 032001 pn=81 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 14 rg,rg34710,1078 –19–27apr99–1/1 preliminary cylinder head&valve checks serial number ( —199,999) make preliminary inspection of cylinder head&valve assembly during disassembly. look for the following conditions: sticking valves: ? carbon deposits on valve stem. ? worn valve guides. ? scored valve stems. ? warped valve stems. ? misaligned/broken valve springs. ? worn/distorted valve seats. ? insufficient lubrication. warped, worn,/distorted valve guides: ? lack of lubrication. ? cylinder head distortion. ? excessive heat. ? unevenly tightened cylinder head cap screws. distorted cylinder head&gasket leakage: ? loss of cylinder head cap screw torque. ? broken cylinder head cap screw. ? overheating from low coolant level operation. ? insufficient liner standout. ? coolant leakage into cylinder causing hydraulic failure of gasket. ? leaking aftercooler. ? cracked cylinder head. ? cracked cylinder liner. ? damaged/incorrect gasket. ? overpowering/overfueling. ? damaged cylinder head/block surfaces. ? improper surface finish on cylinder head. ? improperly tightened cylinder head cap screws. ? faulty gasket installation (misaligned) worn/broken valve seats: ? misaligned valves. ? distorted cylinder head. ? carbon deposits on seats due to incomplete combustion. ? valve spring tension too weak. ? excessive heat. ? improper valve clearance. ? improper valve timing. ? incorrect valve/seat installed. burned, pitted, worn,/broken valves: ? worn/distorted valve seats. ? loose valve seats. ? worn valve guides. ? insufficient cooling. ? cocked/broken valve springs. ? improper engine operation. ? improper valve train timing. ? faulty valve rotators. ? warped/distorted valve stems. ? “stretched” valves due to excessive spring tension. ? warped cylinder head. ? bent push rods. ? carbon build-up on valve seats. ? rocker arm failure. ? incorrect valve/seat installed. ? incorrect piston-to-valve clearance. improper valve clearance: ? inefficient use of fuel. ? engine starts harder. ? maximum engine power will not be achieved. ? shorter service life of valve train. ? greater chance for engine to overheat. excessive valve recession: ? worn valve guides. ? bent valves. ? debris passed through valve train. ctm86 (20mar01) 02-020-14 powertech? 8.1 l diesel engines — base engine 032001 pn=82 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 15 rg,rg34710,1079 –19–23oct97–1/2 remove valve assembly serial number ( —199,999) rg7228 –un–05dec97 removing valve assemblies a—jde138 valve spring compres*** b—retainer locks c—valve springs d—valve spring caps refer to preliminary cylinder head&valve checks serial number ( —199,999), earlier in this group as valves are removed from head. important: identify all usable parts for correct reassembly in same location as removed. 1. compress valve spring using jde138 valve spring compres*** (a) as shown. 2. remove retaining locks (b) using a small magnet. 3. remove valve spring compres*** from head. 4. remove valve spring cap (d)&valve spring (c). rg,rg34710,1079 –19–23oct97–2/2 rg7229 –un–05dec97 removing valves a—oil shield b—valve 5. remove oil shield (a) from exhaust valves. remove valve (b) from cylinder head. identify valve for reassembly, if valve is to be reused. note: intake valves do not have stem seals. 6. repeat procedure on remaining valves. ctm86 (20mar01) 02-020-15 powertech? 8.1 l diesel engines — base engine 032001 pn=83 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 16 rg,rg34710,1080 –19–27apr99–1/1 inspect&measure valve springs serial number ( —199,999) rg2732 –un–04dec97 valve spring t82054 –un–08nov88 checking valve spring tension 1. inspect valve springs for alignment, wear,&damage. 2. put springs on a flat surface to see that they are square?llel. note: free spring length of 65 mm (2.56 in.) springs differ slightly, but compressed height must be the same. 3. check valve spring tension using d01168a spring compression tester. specification intake valve spring—height 38.1 mm (1.50 in.)@810—880 n (182—198 lb-force) with valve open . height 52.5 mm (2.07 in.)@345—399 n (78—90 lb-force) with valve closed specification exhaust valve spring—height 38.5 mm (1.52 in.)@797—867 n (179—195 lb-force) with valve open height 54.5 mm (2.15 in.)@284—338 n (64—76 lb-force) with valve closed ctm86 (20mar01) 02-020-16 powertech? 8.1 l diesel engines — base engine 032001 pn=84 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 17 rg,rg34710,1081 –19–23oct97–1/1 inspect valve spring caps, wear caps, and retainer locks serial number ( —199,999) rg7230 –un–05dec97 inspecting valve parts a—valve spring caps b—valve wear cap c—retainer locks 1. inspect valve spring caps (a) in area where valve springs&retaining locks seat for excessive wear. replace as needed. 2. inspect retainer locks (c) for excessive wear. replace as needed. 3. inspect valve wear cap (b) contact surfaces. replace wear caps if pitted/worn. rg,rg34710,1082 –19–23oct97–1/1 clean valves serial number ( —199,999) 1. hold each valve firmly against a soft wire wheel on a bench grinder. 2. make sure all carbon is removed from valve head, face and stem. polish valve stem with steel wool/crocus cloth to remove scratch marks left by wire brush. important: any carbon left on valve stem will affect alignment in refacer if valves need to be refaced. ctm86 (20mar01) 02-020-17 powertech? 8.1 l diesel engines — base engine 032001 pn=85 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 18 dpsg,ouo1004,833 –19–27apr99–1/2 inspect&measure valves serial number ( —199,999) rg5795 –un–05dec97 measuring valves a—valve head od b—valve stem od c—valve retainer lock groove 1. thoroughly clean&inspect valves to help determine if they can be restored to a serviceable condition. replace valves that are burned, cracked, eroded, or chipped. 2. inspect valve retainer lock groove (c) on valve stem for damage. also inspect stems for signs of scuffing, which may indicate insufficient valve guide-to-valve stem clearance. replace if defects are evident. 3. measure valve head o.d. (a). compare valve stem o.d. (b) with guide i.d. to determine clearance, as outlined later in this group. specification intake valve stem—od 9.461—9.487 mm (0.3725—0.3735 in.) exhaust valve stem—od 9.436—9.462 mm (0.3715—0.3725 in.) . intake valve head—od 50.87—51.13 mm (2.002—2.012 in.) exhaust valve head—od 46.87—47.13 mm (1.845—1.856 in.) . dpsg,ouo1004,833 –19–27apr99–2/2 rg4234 –un–05dec97 valve face runout check 4. use d05058st valve inspection center to determine if valves are out of round, bent/warped. specification valve face—runout 0.05 mm (0.002 in.) maximum permissible ctm86 (20mar01) 02-020-18 powertech? 8.1 l diesel engines — base engine 032001 pn=86 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 19 rg,rg34710,1084 –19–27apr99–1/1 grind (reface) valves serial number ( —199,999) rg5247 –un–05dec97 valve face angle a—valve face angle important: valve grinding should only be done by experienced personnel familiar with equipment&capable of maintaining required specifications. if necessary to reface valve, grind valve face angle (a) to following specification. specification valve face (intake and exhaust)—angle 29.25° ± 0.25° important: when valve faces are ground, it is important not to nick valve head-to-stem radius with facing stone. a nick could cause the valve to break. radius all sharp edges after grinding. rg,rg34710,1085 –19–27apr99–1/1 inspect&clean cylinder head serial number ( —199,999) 1. inspect combustion face for evidence of physical damage, oil/coolant leakage,/gasket failure prior to cleaning the cylinder head. repair or replace cylinder head if there is evidence of physical damage; such as cracking, abrasion, distortion,/valve seat “torching”. inspect all cylinder head passages for restrictions. 2. scrape gasket material, oil, carbon,&rust from head. use a powered brass/copper wire brush to clean sealing surfaces. important: be sure to remove all plugs before cleaning head, as parts can be damaged/destroyed by hot tank solutions. 3. clean cylinder head in a chemical hot tank,/with solvent&a brush. 4. dry with compressed air&blow out all passages. 5. reinstall plugs removed from cylinder head and tighten to the following specifications. specification cylinder head plugs—torque 60 n?m (44 lb-ft) ctm86 (20mar01) 02-020-19 powertech? 8.1 l diesel engines — base engine 032001 pn=87 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 20 rg,rg34710,1086 –19–27apr99–1/1 check cylinder head combustion face flatness serial number ( —199,999) rg7231 –un–05dec97 checking flatness of cylinder head (1) rg7232 –un–05dec97 checking flatness of cylinder head (2) rg4629 –un–05dec97 location to check for head flatness check cylinder head flatness using d05012st precision straightedge&feeler gauge. check lengthwise, crosswise,&diagonally in several places. if any measurement exceeds specification, the cylinder head must be either resurfaced/replaced. see measure cylinder head thickness serial number ( —199,999) later in this group. specification cylinder head—maximum acceptable out-of-flat over entire length/width . 0.08 mm (0.003 in.) straightness per any 305 mm (12 in.) length . within 0.025 mm (0.001 in.) ctm86 (20mar01) 02-020-20 powertech? 8.1 l diesel engines — base engine 032001 pn=88 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 21 rg,rg34710,1087 –19–27apr99–1/1 measure cylinder head thickness serial number ( —199,999) rg4421 –un–05dec97 cylinder head thickness a—head thickness measure head thickness (a) from valve cover gasket rail-to-combustion face. specification cylinder head—thickness 155.45—155.71 mm (6.120—6.130 in.) wear limit 154.69 mm (6.09 in.) combustion face surface finish (surface mill only to aa finish) 1.5—2.8 micrometers (60—110 micro-in.) . maximum wave depth . 0.012 mm (0.0005 in.) if cylinder head thickness is less than wear limit, do not attempt to resurface. install a new cylinder head. specification resurfacing head—maximum material removal 0.762 mm (0.030 in.) note: if necessary to resurface cylinder head, a maximum of 0.762 mm (0.030 in.) can be ground from new part dimension. remove only what is necessary to restore flatness. important: after resurfacing, check flatness as described earlier&check surface finish on combustion face of head. check valve recess after grinding. see measure valve recess serial number ( —199,999) earlier in this group. valve face may be ground to bring this characteristic within specification. ctm86 (20mar01) 02-020-21 powertech? 8.1 l diesel engines — base engine 032001 pn=89 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 22 rg,rg34710,1088 –19–23oct97–1/1 clean valve guides serial number ( —199,999) rg5346 –un–07nov97 cleaning valve guides use a d17024br end brush to clean valve guides before inspection/repair. note: a few drops of light oil/kerosene will help to fully clean the guide. rg,rg34710,1089 –19–23oct97–1/1 measure valve guides serial number ( —199,999) rgr23984 –un–12jan98 a—valve guides b—telescope gauge measure valve guides (a) for wear using a telescope gauge (b)μmeter. specification valve guide—id 9.51—9.54 mm (0.3745—0.3755 in.) in new head new guide-to-exhaust valve stem—clearance 0.051—0.102 mm (0.002—0.004 in.) specification new guide-to-intake valve stem—clearance 0.025—0.076 mm (0.001—0.003 in.) note: worn guides can allow a clearance of 0.15 mm (0.006 in.)&still be acceptable. worn guides may be knurled to return them to specified clearance if valve-to-guide clearance is 0.25 mm (0.010 in.)/less. if clearance exceeds 0.25 mm (0.010 in.), install oversize valves. important: always knurl exhaust valve guides before reaming to assure proper valve guide-to-stem clearance. ctm86 (20mar01) 02-020-22 powertech? 8.1 l diesel engines — base engine 032001 pn=90 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 23 rg,rg34710,1090 –19–23oct97–1/1 knurl valve guides serial number ( —199,999) rgr26141 –un–12jan98 knurling valve guides a—knurler b—reamer c—speed reducer d—lubricant 1. use jt05949 (formerly d20002) valve guide knurler kit to knurl valve guides. note: use tool set exactly as directed by the manufacturer. 2. after knurling, ream valve guide to finished size to provide specified stem-to-guide clearance. rg,rg34710,1091 –19–23oct97–1/1 clean&inspect valve seats serial number ( —199,999) r26142n –un–09dec88 cleaning valve seats 1. use an electric hand drill with d17024br wire cleaning brush/equivalent brush to remove all carbon on valve seats. 2. check seats for cracks, pits,/excessive wear. 3. check entire combustion face for rust, scoring, pitting, or cracks. ctm86 (20mar01) 02-020-23 powertech? 8.1 l diesel engines — base engine 032001 pn=91 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 24 rg,rg34710,1092 –19–23oct97–1/1 measure valve seats serial number ( —199,999) rg5248 –un–05dec97 measuring valve seats a—valve seat insert b—valve seat angle c—valve seat width d—valve seat runout 1. measure valve seats for proper specifications listed below. 2. using d11010kw eccentrimeter, measure valve seat runout (d). 3. if valve seat is not within specification, recondition valve seat by grinding/replace valve seat inserts (a) if reconditioning is not possible. see grind valve seats serial number ( —199,999)/see install valve seat inserts serial number ( —199,999), later in this group. specification valve seat—angle . 30° ± 0.50° maximum runout . 0.051 mm (0.0020 in.) specification exhaust valve seat—width 2.0—3.8 mm (0.079—0.150 in.) specification intake valve seat—width 1.4—3.8 (0.055—0.150 in.) ctm86 (20mar01) 02-020-24 powertech? 8.1 l diesel engines — base engine 032001 pn=92 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 25 rg,rg34710,1093 –19–23oct97–1/2 grind valve seats serial number ( —199,999) r26143n –un–09dec88 grinding valve seats rg5248 –un–05dec97 measuring valve seats a—valve seat insert b—valve seat angle c—valve seat width d—valve seat runout important: valve seat grinding should only be done by experienced personnel familiar with equipment&capable of maintaining required specifications. always keep work area clean when grinding valve seats. a 120-grit stone must be used for grinding both intake and exhaust valve seat inserts (a). using jt05893 heavy-duty seat grinder set, grind valve seats to obtain correct valve recess in cylinder head. see measure valve recess serial number ( —199,999) earlier in this group. be sure valve guide bores are clean before grinding valve seats. see clean valve guides serial number ( —199,999) earlier in this group. if valve seats need grinding, only a few seconds are required to recondition the average valve seat. avoid the tendency to grind off too much. do not use excessive pressure on the grinding stone. 1. check the seat width (c)&contact pattern between the seat&valve with bluing. seat width must be maintained within specification. use a vernier caliper or scale to measure seat width. thoroughly clean seat area after grinding&replace valves&valve seat inserts as necessary. note: valve seat width can be reduced with a narrowing stone. this will change the angle (b) at the top of the seat&increase the diameter. if valve seat width is too narrow, valve may burn/erode. varying the width changes the fine contact between valve face&seat. 2. always measure valve seat runout after grinding using d11010kw eccentrimeter&check recess in cylinder head after grinding as described later. ctm86 (20mar01) 02-020-25 powertech? 8.1 l diesel engines — base engine 032001 pn=93 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 rg,rg34710,1093 –19–23oct97–2/2 specification valve seat grinding—angle 30° ± 0.50° exhaust width . 2.0—3.8 mm (0.079—0.150 in.) intake width 1.4—3.8 mm (0.055—0.150 in.) maximum seat runout . 0.051 mm (0.0020 in.) 26 rg,rg34710,1094 –19–23oct97–1/1 remove valve seat inserts serial number ( —199,999) rg5306 –un–07nov97 removing valve seat inserts rg5605 –un–05dec97 heating valve seat inserts a—valve seat puller in some cases the valve seat bore in the cylinder head may become damaged/oversized&will require machining. in this case, oversize inserts are available in 0.25 mm (0.010 in.) oversize only. specification oversize inserts—width . 0.25 mm (0.010 in.) important: be careful not to damage cylinder head when removing seats. 1. remove valve seat insert (if necessary) with jde41296 valve seat puller (a). adjusting screw on puller may need to be retightened during removal of inserts. valve seat inserts may be also removed using the following method: ? carefully heat insert at four points around face until insert becomes red hot. allow seat to cool and carefully pry out the insert(s) with a screwdriver. 2. after removal of inserts, thoroughly clean area around valve seat bore&inspect for damage/cracks. ctm86 (20mar01) 02-020-26 powertech? 8.1 l diesel engines — base engine 032001 pn=94 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 27 rg,rg34710,1095 –19–23oct97–1/1 install valve seat inserts serial number ( —199,999) rg5653 –un–31oct97 installing valve seat inserts a—driver b—valve seat installer 1. use the jde7 driver (a) along with jdg605 valve seat installer (b) to drive inserts into place. the larger end of jdg605 installer is used to install intake valves and the smaller end is used to install exhaust valves. 2. install new/refaced valves&check valve recess. see measure valve recess serial number ( —199,999) earlier in this group. 3. grind valve seats as required to maintain correct valve recess&valve-to-seat seal. see grind valve seats serial number ( —199,999) earlier in this group. rg,rg34710,1096 –19–23oct97–1/3 inspect&clean cylinder head nozzle bore serial number ( —199,999) rg5251 –un–14dec88 cleaning cylinder head nozzle bores 1. inspect condition of threads for gland nut. threads are metric (m28 x 1.5). 2. inspect condition of nozzle seating surface in cylinder head. cylinder head threads&nozzle seating surface must be free of debris&carbon deposits. important: if the injection nozzle gland nut threads are not clean, a false torque reading may be obtained when the injection nozzle is installed. this may prevent the injection nozzle from seating properly in the cylinder head. 3. clean threads which have light foreign deposits using a drill&the d17030br thread cleaning brush. work brush up&down several times to clean threads. ctm86 (20mar01) 02-020-27 powertech? 8.1 l diesel engines — base engine 032001 pn=95 continued on next page cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 28 rg,rg34710,1096 –19–23oct97–2/3 rg5252 –un–06dec88 using tap on nozzle bore threads a—tap 4. clean threads with heavy foreign deposits/clean up damaged threads using the jdf5 tap (m28 x 1.5 mm) or an equivalent m28 x 1.5 mm (metric) tap (a). be sure to start tap straight to avoid possible cross-threading. a light coat of grease on tap will help collect foreign deposits on tap&prevent them from falling into the nozzle bore. rg,rg34710,1096 –19–23oct97–3/3 rg5253 –un–06dec88 cleaning nozzle seating surface a—nozzle seat reamer 5. clean nozzle seating surface by using the jdg609 nozzle seat reamer (a) to remove carbon. 6. blow out debris with compressed air&thoroughly clean all nozzle bores. ctm86 (20mar01) 02-020-28 powertech? 8.1 l diesel engines — base engine 032001 pn=96 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 29 rg,rg34710,1097 –19–23oct97–1/1 clean&inspect push rods serial number ( —199,999) t81233 –un–01nov88 checking valve push rods for straightness 1. clean push rods with solvent&compressed air. 2. check push rods for straightness by rolling on a flat surface. 3. inspect contact ends for wear&damage. 4. replace defective push rods. rg,rg34710,1098 –19–23oct97–1/1 inspect&clean ventilator outlet hose serial number ( —199,999) 1. check ventilator outlet hose on rocker arm cover for bent/damaged condition. replace if necessary. 2. clean ventilator hose if restricted. ctm86 (20mar01) 02-020-29 powertech? 8.1 l diesel engines — base engine 032001 pn=97 cylinder head&valv, es repair&adjustment s. n. ( —199,999) 02 020 30 rg,rg34710,1099 –19–23oct97–1/1 clean&inspect top deck of cylinder block serial number ( —199,999) 1. remove gasket material, rust, carbon,&other foreign material from top deck. gasket surface must be clean. 2. use compressed air to remove all loose foreign material from cylinders&top deck. 3. clean all cylinder head mounting cap screw holes using jdg681/an equivalent 9/16-12 unc-2a tap about 88.9 mm (3.5 in.) long. use compressed air to remove debris&any fluids which may be present in the cap screw holes. 4. measure top deck flatness. see measure cylinder block in group 030. ctm86 (20mar01) 02-020-30 powertech? 8.1 l diesel engines — base engine 032001 pn=98 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 31 rg,rg34710,1100 –19–23oct97–1/1 measure cylinder liner standout (height above block) serial number ( —199,999) rg7144 –un–28jul94 bolting down cylinder liners rg7145 –un–26nov97 checking cylinder liner height above block a—jdg451 gauge b—dial indicator 1. bolt down liners using cap screws&flat washers in the seven locations as shown. flat washers should be at least 3.18 mm (1/8 in.) thick. tighten cap screws to 68 n?m (50 lb-ft) to achieve an accurate standout reading. note: liners having obvious defects must be replaced. 2. using jdg451 gauge (a) along with d17526ci (english)/d17527ci (metric scale) dial indicator (b) or kjd10123 gauge, measure the height of bolted down liners that are not obviously defective before removal from block. note: variations in measurement readings may occur within one cylinder and/or between adjacent cylinders. 3. measure each liner in four places, approximately at 1, 5, 7&11 o’clock positions as viewed from the rear of the engine (flywheel end). record all measurements by cylinder number&compare to the following specifications. specification liner—height above block 0.051—0.127 mm (0.002—0.005 in.) above block . 4. remove any liner that does not meet standout specification at any location&install liner shims or replace piston/liner sets as necessary. seeinstall liner shims—if required in group 030. ctm86 (20mar01) 02-020-31 powertech? 8.1 l diesel engines — base engine 032001 pn=99 cylinder head&valves repair&adjustment s. n. ( —199,999) 02 020 32 rg,rg34710,1101 –19–23oct97–1/3 assemble valve assembly serial number ( —199,999) rg7229 –un–05dec97 seal on exhaust valve stem a—valve stem seals b—exhaust valve stems remember valve stem seals (a) are installed onto exhaust valve stems (b) only. valves are marked on the head as follows: intake (“i 30”). exhaust (“e 30”). 1. apply ar44402 valve stem lubricant/clean engine oil to valve stems&guides. note: exhaust valve stem oil shields will not seat on valve guide tower; they ride up&down with valve stem. 2. install reconditioned/new valves in head. reconditioned valves must be installed in same location from which removed. note: valve stems must move freely in guide bore and seat properly with insert. 3. install oil shield onto exhaust valve stem until shield bottoms on valve guide tower. rg,rg34710,1101 –19–23oct97–2/3 rg7228 –un–05dec97 installing valve assemblies a—jde138 valve spring compres*** b—valve retainer locks c—valve spring d—valve spring cap note: there is no top/bottom to valve springs (c); they may be installed either way. 4. install valve spring&spring cap (d). spring must seat in machined counterbore of head. 5. compress valve springs with jde138 valve spring compres***

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska