详细描述

约翰迪尔联合收割机应用的发动机零件

设备型号

备注

3300

Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1185

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

9570 STS

Piston (m) RE515037 Tier 2 & Tier 3

2256

High Compression Piston. To ESN 199,999. Tier 1

9760 STS

Low Compression Piston. To ESN 199,999. Tier 1

955

Con Rod (m): R80034, Piston (m): RE30250

W330

Piston (m) RE527039 Tier 2 & Tier 3

9560 STS

Piston (m) RE507758 Tier 2 & Tier 3

9580i WTS

High Compression Piston. To ESN 199,999. Tier 1

9560i STS

9.0 Liter Tier 2 & Tier 3

4320

From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

T550

Piston (m) RE521616 Tier 2 & Tier 3

1550WTS

Piston (m) RE515037 Tier 2 & Tier 3

9640i WTS

Low Compression Piston. To ESN 199,999. Tier 1

T660

9.0 Liter Tier 2 & Tier 3

940

Con Rod (m): R80034, Piston (m): RE30250

2066

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

9580I WTS

Piston (m) RE515037 Tier 2 & Tier 3

2258

High Compression Piston. To ESN 199,999. Tier 1

9780 CTS

Low Compression Piston. To ESN 199,999. Tier 1

975

Con Rod (m): R80034, Piston (m): RE30250

1450CWS

Piston (m) RE521616 Tier 2 & Tier 3

9560I WTS

Piston (m) RE507758 Tier 2 & Tier 3

9640 WTS

High Compression Piston. To ESN 199,999. Tier 1

9660 STS

9.0 Liter Tier 2 & Tier 3

6600

From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

W540

Piston (m) RE521616 Tier 2 & Tier 3

9540I WTS

Piston (m) RE515037 Tier 2 & Tier 3

9650 CTS

Low Compression Piston. To ESN 199,999. Tier 1

T670

9.0 Liter Tier 2 & Tier 3

942

Con Rod (m): R80034, Piston (m): RE30250

9500

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

S550 STS

Piston (m) RE515037 Tier 2 & Tier 3

2264

High Compression Piston. To ESN 199,999. Tier 1

9780i CTS

Low Compression Piston. To ESN 199,999. Tier 1

985

Con Rod (m): R80034, Piston (m): RE30250

1450WTS

Piston (m) RE521616 Tier 2 & Tier 3

9570 STS

Piston (m) RE507758 Tier 2 & Tier 3

9640i WTS

High Compression Piston. To ESN 199,999. Tier 1

9670 STS

9.0 Liter Tier 2 & Tier 3

7700

From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

W550

Piston (m) RE521616 Tier 2 & Tier 3

9560 STS

Piston (m) RE515037 Tier 2 & Tier 3

9650 STS

Low Compression Piston. To ESN 199,999. Tier 1

W650

9.0 Liter Tier 2 & Tier 3

6602

Con Rod (m): R80034, Piston (m): RE30250

9600

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

T550

Piston (m) RE515037 Tier 2 & Tier 3

2266

High Compression Piston. To ESN 199,999. Tier 1

9850i WTS

Low Compression Piston. To ESN 199,999. Tier 1

1055

Con Rod (m): R80034, Piston (m): RE30250

1550CWS

Piston (m) RE521616 Tier 2 & Tier 3

9580I WTS

Piston (m) RE507758 Tier 2 & Tier 3

2264

Low Compression Piston. To ESN 199,999. Tier 1

9760 STS

9.0 Liter Tier 2 & Tier 3

6620

Con Rod (m) R66922, R58852, R41423

1450CWS

Piston (m) RE515037 Tier 2 & Tier 3

9560I WTS

Piston (m) RE515037 Tier 2 & Tier 3

9660 CTS

Low Compression Piston. To ESN 199,999. Tier 1

W660

9.0 Liter Tier 2 & Tier 3

945

Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

9965

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

W540

Piston (m) RE515037 Tier 2 & Tier 3

9510

High Compression Piston. To ESN 199,999. Tier 1

CTS

Low Compression Piston. To ESN 199,999. Tier 1

1075

Con Rod (m): R80034, Piston (m): RE30250

1550WTS

Piston (m) RE521616 Tier 2 & Tier 3

S550 STS

Piston (m) RE507758 Tier 2 & Tier 3

2266

Low Compression Piston. To ESN 199,999. Tier 1

9770 STS

9.0 Liter Tier 2 & Tier 3

6620

Con Rod (m) R57303, R67320

1450WTS

Piston (m) RE515037 Tier 2 & Tier 3

9570 STS

Piston (m) RE515037 Tier 2 & Tier 3

9660 STS

Low Compression Piston. To ESN 199,999. Tier 1

9780CTS

9.0 Liter Tier 2 & Tier 3

952

Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

8760

To ESN 499,999

W550

Piston (m) RE515037 Tier 2 & Tier 3

9550

High Compression Piston. To ESN 199,999. Tier 1

CTS II

Low Compression Piston. To ESN 199,999. Tier 1

9400

Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

9540I WTS

Piston (m) RE521616 Tier 2 & Tier 3

T550

Piston (m) RE507758 Tier 2 & Tier 3

9610

Low Compression Piston. To ESN 199,999. Tier 1

C670

9.0 Liter Tier 2 & Tier 3

7720

Con Rod (m) R57303, R67320

1550CWS

Piston (m) RE515037 Tier 2 & Tier 3

9580I WTS

Piston (m) RE515037 Tier 2 & Tier 3

9660 WTS

Low Compression Piston. To ESN 199,999. Tier 1

1052

Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

9410

Piston (m) RE55512, RE505102

1450CWS

Piston (m) RE507758 Tier 2 & Tier 3

9510 SH

High Compression Piston. To ESN 199,999. Tier 1

9560 STS

Low Compression Piston. From ESN 200,000. Tier 2.

9400

Liter designated, Con Rod (m): R80032, Piston (m): RE22678

9560 STS

Piston (m) RE521616 Tier 2 & Tier 3

W540

Piston (m) RE507758 Tier 2 & Tier 3

9650

Low Compression Piston. To ESN 199,999. Tier 1

S560

9.0 Liter Tier 2 & Tier 3

8820

Con Rod (m) R57303, R67320

1550WTS

Piston (m) RE515037 Tier 2 & Tier 3

S550 STS

Piston (m) RE515037 Tier 2 & Tier 3

9660i WTS

Low Compression Piston. To ESN 199,999. Tier 1

1155

Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

1450CWS

Piston (m) RE527039 Tier 2 & Tier 3

1450WTS

Piston (m) RE507758 Tier 2 & Tier 3

9550 SH

High Compression Piston. To ESN 199,999. Tier 1

9640

9.0 Liter Tier 2 & Tier 3

9400

Liter designated

9560I WTS

Piston (m) RE521616 Tier 2 & Tier 3

W550

Piston (m) RE507758 Tier 2 & Tier 3

9660

Low Compression Piston. To ESN 199,999. Tier 1

S660 STS

9.0 Liter Tier 2 & Tier 3

6602

Con.Rod (m) R71074 (P/N AR93341)

9540I WTS

Piston (m) RE515037 Tier 2 & Tier 3

T550

Piston (m) RE515037 Tier 2 & Tier 3

9680 WTS

Low Compression Piston. To ESN 199,999. Tier 1

950

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

1450WTS

Piston (m) RE527039 Tier 2 & Tier 3

1550CWS

Piston (m) RE507758 Tier 2 & Tier 3

9560 WTS

High Compression Piston. To ESN 199,999. Tier 1

9660

9.0 Liter Tier 2 & Tier 3

6600

Block (m) R49470, R49650, R59850, R72128, R87558

9570 STS

Piston (m) RE521616 Tier 2 & Tier 3

1450CWS

Piston (m) RE515037 Tier 2 & Tier 3

9560 STS

Low Compression Piston. To ESN 199,999. Tier 1

S670 STS

9.0 Liter Tier 2 & Tier 3

6620

Con.Rod (m) R71074 (P/N AR93341)

9560 STS

Piston (m) RE515037 Tier 2 & Tier 3

W540

Piston (m) RE515037 Tier 2 & Tier 3

9680i WTS

Low Compression Piston. To ESN 199,999. Tier 1

960

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

1550CWS

Piston (m) RE527039 Tier 2 & Tier 3

1550WTS

Piston (m) RE507758 Tier 2 & Tier 3

9560i WTS

High Compression Piston. To ESN 199,999. Tier 1

9680

9.0 Liter Tier 2 & Tier 3

7700

Block (m) R49470, R49650, R59850, R72128, R87558

9580I WTS

Piston (m) RE521616 Tier 2 & Tier 3

1450WTS

Piston (m) RE515037 Tier 2 & Tier 3

9580 WTS

Low Compression Piston. To ESN 199,999. Tier 1

S670 STS

9.0 Liter Tier 2 & Tier 3

8820

Con Rod (m) R71074 (P/N AR93341)

9560I WTS

Piston (m) RE515037 Tier 2 & Tier 3

W550

Piston (m) RE515037 Tier 2 & Tier 3

9750 STS

Low Compression Piston. To ESN 199,999. Tier 1

4400

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

1550WTS

Piston (m) RE527039 Tier 2 & Tier 3

9540I WTS

Piston (m) RE507758 Tier 2 & Tier 3

9580 WTS

High Compression Piston. To ESN 199,999. Tier 1

9560 STS

9.0 Liter Tier 2 & Tier 3

4320

To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

S550 STS

Piston (m) RE521616 Tier 2 & Tier 3

1550CWS

Piston (m) RE515037 Tier 2 & Tier 3

9640 WTS

Low Compression Piston. To ESN 199,999. Tier 1

T560

9.0 Liter Tier 2 & Tier 3

约翰迪尔联合收割机应用的发动机零件

| 设备型号 | 备注 |

|---|---|

| 3300 | Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484 |

| 1185 | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 9570 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 2256 | High Compression Piston. To ESN 199,999. Tier 1 |

| 9760 STS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 955 | Con Rod (m): R80034, Piston (m): RE30250 |

| W330 | Piston (m) RE527039 Tier 2 & Tier 3 |

| 9560 STS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9580i WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9560i STS | 9.0 Liter Tier 2 & Tier 3 |

| 4320 | From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558 |

| T550 | Piston (m) RE521616 Tier 2 & Tier 3 |

| 1550WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9640i WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| T660 | 9.0 Liter Tier 2 & Tier 3 |

| 940 | Con Rod (m): R80034, Piston (m): RE30250 |

| 2066 | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 9580I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 2258 | High Compression Piston. To ESN 199,999. Tier 1 |

| 9780 CTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 975 | Con Rod (m): R80034, Piston (m): RE30250 |

| 1450CWS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 9560I WTS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9640 WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9660 STS | 9.0 Liter Tier 2 & Tier 3 |

| 6600 | From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558 |

| W540 | Piston (m) RE521616 Tier 2 & Tier 3 |

| 9540I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9650 CTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| T670 | 9.0 Liter Tier 2 & Tier 3 |

| 942 | Con Rod (m): R80034, Piston (m): RE30250 |

| 9500 | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| S550 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 2264 | High Compression Piston. To ESN 199,999. Tier 1 |

| 9780i CTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 985 | Con Rod (m): R80034, Piston (m): RE30250 |

| 1450WTS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 9570 STS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9640i WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9670 STS | 9.0 Liter Tier 2 & Tier 3 |

| 7700 | From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558 |

| W550 | Piston (m) RE521616 Tier 2 & Tier 3 |

| 9560 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9650 STS | Low Compression Piston. To ESN 199,999. Tier 1 |

| W650 | 9.0 Liter Tier 2 & Tier 3 |

| 6602 | Con Rod (m): R80034, Piston (m): RE30250 |

| 9600 | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| T550 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 2266 | High Compression Piston. To ESN 199,999. Tier 1 |

| 9850i WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 1055 | Con Rod (m): R80034, Piston (m): RE30250 |

| 1550CWS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 9580I WTS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 2264 | Low Compression Piston. To ESN 199,999. Tier 1 |

| 9760 STS | 9.0 Liter Tier 2 & Tier 3 |

| 6620 | Con Rod (m) R66922, R58852, R41423 |

| 1450CWS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9560I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9660 CTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| W660 | 9.0 Liter Tier 2 & Tier 3 |

| 945 | Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115 |

| 9965 | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| W540 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9510 | High Compression Piston. To ESN 199,999. Tier 1 |

| CTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 1075 | Con Rod (m): R80034, Piston (m): RE30250 |

| 1550WTS | Piston (m) RE521616 Tier 2 & Tier 3 |

| S550 STS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 2266 | Low Compression Piston. To ESN 199,999. Tier 1 |

| 9770 STS | 9.0 Liter Tier 2 & Tier 3 |

| 6620 | Con Rod (m) R57303, R67320 |

| 1450WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9570 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9660 STS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 9780CTS | 9.0 Liter Tier 2 & Tier 3 |

| 952 | Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115 |

| 8760 | To ESN 499,999 |

| W550 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9550 | High Compression Piston. To ESN 199,999. Tier 1 |

| CTS II | Low Compression Piston. To ESN 199,999. Tier 1 |

| 9400 | Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278 |

| 9540I WTS | Piston (m) RE521616 Tier 2 & Tier 3 |

| T550 | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9610 | Low Compression Piston. To ESN 199,999. Tier 1 |

| C670 | 9.0 Liter Tier 2 & Tier 3 |

| 7720 | Con Rod (m) R57303, R67320 |

| 1550CWS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9580I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9660 WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 1052 | Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115 |

| 9410 | Piston (m) RE55512, RE505102 |

| 1450CWS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9510 SH | High Compression Piston. To ESN 199,999. Tier 1 |

| 9560 STS | Low Compression Piston. From ESN 200,000. Tier 2. |

| 9400 | Liter designated, Con Rod (m): R80032, Piston (m): RE22678 |

| 9560 STS | Piston (m) RE521616 Tier 2 & Tier 3 |

| W540 | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9650 | Low Compression Piston. To ESN 199,999. Tier 1 |

| S560 | 9.0 Liter Tier 2 & Tier 3 |

| 8820 | Con Rod (m) R57303, R67320 |

| 1550WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| S550 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9660i WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 1155 | Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115 |

| 1450CWS | Piston (m) RE527039 Tier 2 & Tier 3 |

| 1450WTS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9550 SH | High Compression Piston. To ESN 199,999. Tier 1 |

| 9640 | 9.0 Liter Tier 2 & Tier 3 |

| 9400 | Liter designated |

| 9560I WTS | Piston (m) RE521616 Tier 2 & Tier 3 |

| W550 | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9660 | Low Compression Piston. To ESN 199,999. Tier 1 |

| S660 STS | 9.0 Liter Tier 2 & Tier 3 |

| 6602 | Con.Rod (m) R71074 (P/N AR93341) |

| 9540I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| T550 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9680 WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 950 | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 1450WTS | Piston (m) RE527039 Tier 2 & Tier 3 |

| 1550CWS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9560 WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9660 | 9.0 Liter Tier 2 & Tier 3 |

| 6600 | Block (m) R49470, R49650, R59850, R72128, R87558 |

| 9570 STS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 1450CWS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9560 STS | Low Compression Piston. To ESN 199,999. Tier 1 |

| S670 STS | 9.0 Liter Tier 2 & Tier 3 |

| 6620 | Con.Rod (m) R71074 (P/N AR93341) |

| 9560 STS | Piston (m) RE515037 Tier 2 & Tier 3 |

| W540 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9680i WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 960 | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 1550CWS | Piston (m) RE527039 Tier 2 & Tier 3 |

| 1550WTS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9560i WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9680 | 9.0 Liter Tier 2 & Tier 3 |

| 7700 | Block (m) R49470, R49650, R59850, R72128, R87558 |

| 9580I WTS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 1450WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9580 WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| S670 STS | 9.0 Liter Tier 2 & Tier 3 |

| 8820 | Con Rod (m) R71074 (P/N AR93341) |

| 9560I WTS | Piston (m) RE515037 Tier 2 & Tier 3 |

| W550 | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9750 STS | Low Compression Piston. To ESN 199,999. Tier 1 |

| 4400 | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 1550WTS | Piston (m) RE527039 Tier 2 & Tier 3 |

| 9540I WTS | Piston (m) RE507758 Tier 2 & Tier 3 |

| 9580 WTS | High Compression Piston. To ESN 199,999. Tier 1 |

| 9560 STS | 9.0 Liter Tier 2 & Tier 3 |

| 4320 | To ESN 335,845, Block (m): R43310, R45980, R47020, R47110 |

| S550 STS | Piston (m) RE521616 Tier 2 & Tier 3 |

| 1550CWS | Piston (m) RE515037 Tier 2 & Tier 3 |

| 9640 WTS | Low Compression Piston. To ESN 199,999. Tier 1 |

| T560 | 9.0 Liter Tier 2 & Tier 3 |

约翰迪尔 4045 4.5T/H 活塞(米) RE515037 排放 2 & 3

|

| ||||||||||||||||||||||||||||

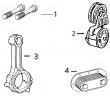

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确操作。

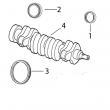

(3)锥形鼻子。

(4)直鼻。

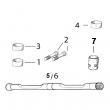

(5)检查应用程序是否正确使用。

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

美国强鹿JOHN DEERE柴油机配件、发动机配件、发电机组: 3029DF120、3029TF158、3029TFU80、3029HFU70、4045HF280、4045TF002、3029DF128、30294045TF258、4045TF275、4045TF220、4045HF285、4045TF258、4045TFU70、4045HF285V07、4045TF220、4045TF120、6068HF120、6068HF475、6068TF220、6068TF001、6068HF158、6135HF485/

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

PE6068HF275BA5E、4045HFU82、4045HFU79、4045HF、6068HF183、6068HFU72、6090HFU75、6068HFUFU79、6068HFU82、6068HF183、6090HFU75、6068HFU74、6090HFU84、4024TF220、6090HF485 6081HF001、6081AF001、6081TF001groove wear rg5230 –un–05dec97 checking piston ring groove wear rg7058 –un–26nov97 checking piston top ring groove rg7059 –un–26nov97 checking piston middle ring groove a—jde55 keystone ring groove wear gauge b—jdg852 half-keystone ring groove wear gauge c—piston with good ring groove d—acceptable clearance e—piston with worn ring groove f—gauge shoulder contacting piston ring land check grooves at several locations around the circumference of piston. 1. use the jde55 ring groove wear gauge (a) to check wear of top full keystone (compression) ring groove. 2. use jdg852 ring groove wear gauge (b) to check wear of middle half-keystone (compression) ring groove. if gauge shoulder contacts ring land of piston, ring groove is worn. replace piston&liner as a set. if ring grooves are good (d), proceed with piston inspection. continued on next page ctm86 (20mar01) 02-030-14 powertech? 8.1 l diesel engines — base engine 032001 pn=164 cylinder block, liners, pistons,&rods repair&adjustment 02 030 15 rg,rg34710,1121 –19–23oct97–2/2 rg5234 –un–05dec97 checking piston oil control ring clearance 3. check oil control ring-to-groove clearance by installing a new ring in groove. 4. measure clearance with a feeler gauge at several points. compare measurements with specifications given below. specification piston oil control ring-to-groove—new part clearance 0.064—0.102 mm (0.0025—0.0040 in.) maximum serviceable clearance . 0.165 mm (0.0065 in.) note: replace piston&liner (as a set) if oil control ring clearance exceeds specifications given. rg,rg34710,1122 –19–23oct97–1/1 inspect piston pin&bore rg5231 –un–05dec97 installing pin in piston rg4984 –un–05dec97 inspecting for piston pin bore wear a—pin b—tapered bore wear c—bore out-of-alignment note: piston pin must be in good condition? worn beyond specification given below. 1. dip piston in clean engine oil. 2. install pin (a) through piston. pin should pass through piston using only light thumb pressure. 3. check taper in piston pin bore by inserting pin from both sides. if pin enters freely, but binds in the center, the bore could be tapered (b). 4. insert pin in piston to check for bore alignment. pin should not “click”/need to be forced into bore on opposite side (c). 5. measure piston pin&piston bore specifications. if either are not within specification, replace pin, piston, and liner. specification piston pin—od 47.597—47.613 mm (1.8739—1.8745 in.) . piston pin bore—id 47.62—47.63 mm (1.8748—1.8752 in.) ctm86 (20mar01) 02-030-15 powertech? 8.1 l diesel engines — base engine 032001 pn=165 cylinder block, liners, pistons,&rods repair&adjustment 02 030 16 rg,rg34710,1123 –19–23oct97–1/2 visually inspect cylinder liners rg4643 –un–05dec97 inspecting cylinder liners a—liner pitting b—liner erosion c—liner thickness d—packing step important: if liner pitting has occurred, check condition of coolant. 1. inspect exterior length of liner for pitting (a). check packing step for erosion (b). if pitting/erosion is observed, measure depth of pits with a fine wire or needle. replace piston&liner if: ? depth of any pit is one-half/more of liner thickness (c). ? depth of erosion is one-half/more of the packing step (d). specification cylinder liner—thickness . 6.05—6.15 mm (0.238—0.242 in.) packing step dimension . 1.45—1.55 mm (0.057—0.061 in.) note: liners are reusable if the depth of pits/erosion is less than one-half the amount specified. when installing reusable liners, rotate 90° from original position. the liners should be also deglazed and new ring sets installed in pistons. continued on next page ctm86 (20mar01) 02-030-16 powertech? 8.1 l diesel engines — base engine 032001 pn=166 cylinder block, liners, pistons,&rods repair&adjustment 02 030 17 rg,rg34710,1123 –19–23oct97–2/2 rg1188 –un–04dec97 cylinder liner defects (exaggerated) a—flange area b—ring travel area 2. visually examine liner i.d. replace piston&liner if: ? the crosshatch honing pattern is not visible immediately below the top ring turn-around area. ? liners are pitted/contain deep vertical scratches that can be detected by the fingernail. 3. carefully examine liner for signs of fatigue, such as fine cracks in the flange area (a)&cracks in the ring travel area (b). note: inspect block for cracks/erosion in the o-ring packing areas. see inspect&clean cylinder block later in this group. ctm86 (20mar01) 02-030-17 powertech? 8.1 l diesel engines — base engine 032001 pn=167 cylinder block, liners, pistons,&rods repair&adjustment 02 030 18 rg,rg34710,1124 –19–23oct97–1/1 cylinder liner manufacturing date code explanation rg6091 –un–27jan92 four-digit date code on cylinder liner a manufacturing four-digit date code will appear on each liner. for example, hj94 means the liner has a hardened bore&was manufactured in october of 1994. hj94 h . liner material type j month liner was manufactured 94 . year liner was manufactured liner material specification: h . hardened liner bore month liner was manufactured: a . january b . february c march d . april e may f . june g july h august i . september j october k . november l . december year liner was manufactured: 94 1994 95 1995 etc. ctm86 (20mar01) 02-030-18 powertech? 8.1 l diesel engines — base engine 032001 pn=168 cylinder block, liners, pistons,&rods repair&adjustment 02 030 19 rg,rg34710,1125 –19–23oct97–1/2 determine piston-to-liner clearance rg7045 –un–05dec97 measuring piston skirt diameter a—15.16 mm (0.597 in.) from the bottom of the piston b—piston skirt diameter c—right angles to piston pin bore 1. measure piston skirt diameter (b) at right angles to piston pin bore (c), 15.16 mm (0.597 in.) from the bottom of the piston (a). 2. record measurement&compare measurement obtained from matching liner. specification piston skirt—od 15.16 mm (0.597 in.) from bottom of piston 115.771—115.789 mm (4.5579—4.5586 in.) continued on next page ctm86 (20mar01) 02-030-19 powertech? 8.1 l diesel engines — base engine 032001 pn=169 cylinder block, liners, pistons,&rods repair&adjustment 02 030 20 rg,rg34710,1125 –19–23oct97–2/2 rg10049 –un–25may99 measure liner important: always measure liners at room temperature. 3. measure liner bore parallel to piston pin at top end of ring travel (a). 4. measure bore in same position at bottom end of ring travel (b). 5. measure bore at right angle to piston pin at top end of ring travel (c). 6. measure bore in same position at bottom end of ring travel (d). 7. compare measurements a, b, c,&d to determine if liner is tapered/out-of-round. 8. compare liner i.d. with matched piston o.d. specification cylinder liner—id 115.865—115.895 mm (4.5616—4.5628 in.) . od (coolant jacket area) 127.94—128.24 mm (5.037—5.049 in.) . od (at upper bore) 129.08—129.14 mm (5.082—5.084 in.) od (at lower bore) 125.044—125.120 mm (4.923—4.926 in.) id of upper bore in block for seating liners 129.155—129.205 mm (5.085—5.087 in.) id of lower bore in block for seating liners 125.133—125.183 mm (4.9265—4.9285 in.) liner-to-block clearance at upper bore 0.026—0.126 mm (0.001—0.005 in.) . liner-to-block clearance at lower bore 0.012—0.140 mm (0.0005—0.0055 in.) . maximum out-of-round . 0.051 mm (0.0020 in.) maximum wear/taper in ring travel area . 0.051 mm (0.0020 in.) maximum piston-to-liner—new part clearance (at bottom of skirt) 0.076—0.124 mm (0.0030—0.0049 in.) maximum clearance . 0.152 mm (0.0060 in.) replace piston&liners (as a set) if they exceed wear specifications given. ctm86 (20mar01) 02-030-20 powertech? 8.1 l diesel engines — base engine 032001 pn=170 cylinder block, liners, pistons,&rods repair&adjustment 02 030 21 dpsg,ouo1004,884 –19–08jun99–1/4 inspect rod&cap rg3749 –un–04dec97 tongue-and-groove rod&cap rg10052 –un–09jun99 precision joint? rod&cap rg4982 –un–05dec97 clamping rod in vise a—tongue-and-groove joints b—cap screw holes c—precision joint? mating surfaces 1. inspect rod&cap for wear/damage, such as chips or nicks in the joint areas (a). important: do not nick the joint surfaces of rod and cap. this is very critical on precision joint? rods to assure proper seating. never scrape joint surfaces (c) with a wire brush/other tool; the interlocking mating surfaces must be preserved. 2. inspect in&around cap screw holes (b) in cap. if any defects are found, replace rod&cap. important: if replacing a connecting rod, use the same type of joint design. do not intermix precision joint? rods and tongue-and-groove rods on the same engine. see parts catalog for recommendations. 3. carefully clamp rod in a soft-jawed vise (cap end upward). 4. install cap without bearing. important: never use new connecting rod cap screws when checking rod bore i.d. use new cap screws only for final assembly of connecting rods. 5. on tongue-and-groove connecting rods: initially tighten blind-hole cap screw, then, tighten open-hole cap screw to the following specifications. specification tongue-and-groove connecting rod cap screw—initial torque . 27 n?m (20 lb-ft) next, tighten rod cap screws to the following specifications. precision joint is a trademark of deere & company ctm86 (20mar01) 02-030-21 powertech? 8.1 l diesel engines — base engine 032001 pn=171 continued on next page cylinder block, liners, pistons,&rods repair&adjustment 02 030 22 dpsg,ouo1004,884 –19–08jun99–2/4 specification tongue-and-groove connecting rod cap screw—final torque 75 n?m (55 lb-ft) plus 90–100° turn clockwise . see torque-turn connecting rod cap screws, described later in this group. 6. on precision joint? connecting rods: initially tighten rod cap screw closest to pi, ston end, then tighten other cap screw to the following specifications. specification precision joint? connecting rod cap screw—torque 95 n?m (71 lb-ft) plus 90–100° turn clockwise see torque-turn connecting rod cap screws , described later in this group. precision joint is a trademark of deere & company dpsg,ouo1004,884 –19–08jun99–3/4 rg7140 –un–05dec97 measuring connecting rod&cap bore 7. using an inside micrometer, measure rod bore at center of bore&record measurements as follows: ? at right angle to rod/cap joint (a). ? at 45° left of measurement step “a” (b). ? at 45° right of measurement step “a” (c). specification connecting rod bore (without bearings)—id 81.051—81.077 mm (3.191—3.192 in.) 8. compare the measurements. if difference between the greatest&least measurement is more than 0.04 mm (0.0016 in.), the rod&cap are out-of-round. replace both connecting rod&cap. specification connecting rod bore—maximum out-of-round 0.025 mm (0.0010 in.) ctm86 (20mar01) 02-030-22 powertech? 8.1 l diesel engines — base engine 032001 pn=172 continued on next page cylinder block, liners, pistons,&rods repair&adjustment 02 030 23 dpsg,ouo1004,884 –19–08jun99–4/4 rg7141 –un–05dec97 measuring pin bore-to-crankshaft bore a—center-to-center dimension 9. measure rod’s piston pin bore-to-crankshaft bore center-to-center dimension (a)&compare with specification given. if measurement is not within specification, replace rod. specification centerline of piston pin bore-to-crankshaft bore— dimension 222.20—222.30 mm (8.748—8.752 in.) dpsg,ouo1004,891 –19–18may99–1/2 inspect piston pins&bushings rg3172 –un–04dec97 a—connecting rod checking piston pin&rod b—piston pin 1. insert piston pin (b) through piston pin bushing and carefully clamp in a soft-jawed vise. 2. rotate connecting rod (a) back&forth several times to make sure connecting rod moves freely on piston pin. 3. remove piston pin from connecting rod. continued o, n next page ctm86 (20mar01) 02-030-23 powertech? 8.1 l diesel engines — base engine 032001 pn=173 cylinder block, liners, pistons,&rods repair&adjustment 02 030 24 dpsg,ouo1004,891 –19–18may99–2/2 rg4983 –un–05dec97 inspecting piston pin bores a—tapered bore b—bell-mouthed bore 4. insert pin from either side of rod bushing. if pin is free on one end, but tight on the other, the bore could be tapered (a). if pin enters freely from both sides, but is tight in the center, bore is bell-mouthed (b). 5. measure i.d. of rod pin bushing&o.d. of piston pin. compare measurements with specifications given below: specification piston pin—od 47.597—47.613 mm (1.8739—1.8745 in.) . piston pin bore in piston—id 47.620—47.630 mm (1.8748—1.8752 in.) . installed connecting rod pin bushing (after boring)—id 47.655—47.681 mm (1.8762—1.8772 in.) connecting rod pin-to-bushing— oil clearance 0.042—0.084 mm (0.0017—0.0033 in.) . wear limit 0.102 mm (0.0040 in.) 6. if necessary, remove&replace piston pin bushing. see remove piston pin bushing, clean and inspect pin bore, later in this group. ctm86 (20mar01) 02-030-24 powertech? 8.1 l diesel engines — base engine 032001 pn=174 cylinder block, liners, pistons,&rods repair&adjustment 02 030 25 rg,rg34710,1130 –19–23oct97–1/1 remove piston pin bushing, clean and inspect pin bore rg4985 –un–08dec97 removing piston pin bushing from rod a—jdg339 cup b—jdg338 adapter c—jde98-4 driver d—std36104 forcing screw with washer 1. if necessary, remove pin bushing with the jdg337 and jde98a connecting rod bushing service sets. use the following tools from the service sets: ? jdg339 cup (a) ? jdg338 adapter (b) ? jde98-4 driver (c) ? std36104 forcing screw with washer (d) important: use care to properly align the jde98-4 driver with bushing so that the connecting rod bushing bore is not damaged. 2. clean rod bushing bore using a medium grit emery cloth, as burrs will distort bushing. install bushing on opposite side of rod burr. 3. measure rod bushing bore in three places approximately 45° apart. compare the measurements with the specifications given below: specification connecting rod pin bore— diameter without bushing 52.354—52.380 mm (2.0612—2.0622 in.) . connecting rod pin bore-to-bushing—press fit 0.084—0.147 mm (0.0033—0.0058 in.) . installed service connecting rod pin bushing (before boring)—id 47.58—47.63 mm (1.8732—1.8751 in.) installed service connecting rod pin bushing (after boring)—id 47.655—47.681 mm (1.8762—1.8772 in.) . important: if piston pin bushing bore diameter in rod is not within specification or bushing has spun in rod, discard rod and replace with a new one. ctm86 (20mar01) 02-030-25 powertech? 8.1 l diesel engines — base engine 032001 pn=175 cylinder block, liners, pistons,&rods repair&adjustment 02 030 26 rg,rg34710,1126 –19–18may99–1/1 measure liner flange rg4727 –un–05dec97 measuring liner flange measure cylinder liner flange thickness at several locations&compare with specification given below. if liner flange is not within specification, either use liner shims as needed/replace piston&liner as a set if shims don’t bring liner standout within specification. see recheck cylinder liner standout&see install liner shims—if required, later in this group.) specification cylinder liner flange—thickness 11.989—12.039 mm (0.472—0.474 in.) od 135.10—135.16 mm (5.319—5.321 in.) . ctm86 (20mar01) 02-030-26 powertech? 8.1 l diesel engines — base engine 032001 pn=176 cylinder block, liners, pistons,&rods repair&adjustment 02 030 27 dpsg,ouo1004,885 –19–14may99–1/3 inspect&measure connecting rod bearings rg7046 –un–05dec97 connecting rod bearings a—rod cap b—rod c—bearings inspect connecting rod bearings for wear/damage. important: each rod bearing half has a built-in “relief”/lube oil pocket on the inner surface. this relief must not be confused as a worn/damaged spot. important: never use new connecting rod cap screws when checking rod bearing i.d. use new cap screws only for final assembly of connecting rods. rod bearing-to-journal oil clearance can be checked with plastigage?, if rod is connected to crankshaft. if rod is out of engine, measure i.d. of connecting rod bearings and compare with o.d. of crankshaft journal. 1. with crankshaft removed, measure connecting rod journal o.d. at several points. 2. carefully clamp rod in a soft-jawed vise&install connecting rod cap (a) on rod (b) with bearings (c) in correct position. 3. on tongue-and-groove connecting rods: initially tighten blind-hole cap screw, then, tighten open-hole cap screw to the following specifications. specification tongue-and-groove connecting rod cap screw—initial torque . 27 n?m (20 lb-ft) next, tighten rod cap screws to the following specifications. specification tongue-and-groove connecting rod cap screw—final torque 75 n?m (55 lb-ft) plus 90–100° turn clockwise . see torque-turn connecting rod cap screws, described later in this group. plastigage is a registered trademark of dana corp. ctm86 (20mar01) 02-030-27 powertech? 8.1 l diesel engines — base engine 032001 pn=177 continued on next page cylinder block, liners, pistons,&rods repair&adjustment 02 030 28 dpsg,ouo1004,885 –19–14may99–2/3 4. on precision joint? connecting rods: initially tighten rod cap screw closest to piston end, then tighten other cap screw to the following specifications. specification precision joint? connecting rod cap screw—torque 95 n?m (71 lb-ft) plus 90–100° turn clockwise see torque-turn connecting rod cap screws , described later in this group. precision joint is a trademark of deere & company dpsg,ouo1004,885 –19–14may99–3/3 rg3824 –un–04dec97 measuring connecting rod bearings a—inside micrometer 5. using an inside micrometer (a) measure i.d. of bearing. 6. subtract o.d. of crankshaft journals from i.d. of rod bearings to obtain oil clearance. 7. compare measurements with the following specifications. specification crankshaft rod journal—od 76.150—76.180 mm (2.9980—2.9992 in.) assembled connecting rod bearing—id 76.210—76.260 mm (3.0004—3.0024 in.) . connecting rod bearing-to-journal (new parts)— oil clearance 0.030—0.110 mm (0.0012—0.0044 in.) . 8. if bearings are worn/not within specification, replace connecting rod bearings. ctm86 (20mar01) 02-030-28 powertech? 8.1 l diesel engines — base engine 032001 pn=178 cylinder block, liners, pistons,&rods repair&adjustment 02 030 29 rg,rg34710,1131 –19–23oct97–1/1 install piston pin bushing in connecting rod rg4986 –un–05dec97 installing piston pin bushing in rod a—std36104 forcing screw with washer b—jde98a driver c—jdg338 adapter d—service bushing e—jde98-3 pilot f—jde339 cup important: always push new bushing into rod from back side&burnish bushing after installation for proper form&seating in rod bore. 1. lubricate rod bushing bore&bushing with clean engine oil. install bushing using the jdg337 and jde98a connecting rod bushing service sets. use the following tools from the above sets and assemble in sequence as shown: ? std36104 forcing screw with washer (a) ? jde98a drive (b) ? jdg338 adapter (c) ? service bushing (d) ? jde98-3 pilot (e) ? jde339 cup (f) important: boring of the rod bushing should be done only by experienced personnel on equipment capable of maintaining bushing specification. 2. after installation, bore i.d. of newly installed bushing to the following specifications. specification connecting rod pin bushing (after boring)—id 47.655—47.681 mm (1.8762—1.8772 in.) remove all residue from boring operation. 3. check rod pin-to-bushing clearance. see inspect piston pins&bushings, earlier in this group. 4. replace rod pin as required. ctm86 (20mar01) 02-030-29 powertech? 8.1 l diesel engines — base engine 032001 pn=179 cylinder block, liners, pistons,&rods repair&adjustment 02 030 30 rg,rg34710,1132 –19–23oct97–1/1 complete disassembly of cylinder block (if required) if complete inspection&“hot tank” cleaning of cylinder block is required, refer to the appropriate group for removal of all external&internal mounted components listed below: 1. remove crankshaft&pulley if not previously removed. (group 040.) 2. remove all remaining lubrication system components. (group 060.) 3. remove coolant pump&all remaining cooling system components (group 070.) 4. remove timing gear train&camshaft. (group 050.) 5. remove fuel injection pump&fuel filter assembly. (group 090.) 6. if necessary to “hot tank” the block, remove oil gallery plugs, coolant gallery plugs, piston cooling orifices&the engine serial number plate. rg,rg34710,1133 –19–23oct97–1/1 remove&clean piston cooling orifices rg10211 –un–18jun99 piston cooling orifices in block a—piston cooling orifices 1. remove all six (four shown) piston cooling orifices (a) and inspect each cooling orifice to make sure it is not plugged/damaged. 2. use a soft wire&compressed air to clean orifice. replace if condition is questionable. important: a piston cooling orifice failure could cause damage to pistons, piston pins, rod pin bushings,&liners. if a piston cooling orifice is left out, low/no oil pressure will result. ctm86 (20mar01) 02-030-30 powertech? 8.1 l diesel engines — base engine 032001 pn=180 cylinder block, liners, pistons,&rods repair&adjustment 02 030 31 rg,rg34710,1134 –19–23oct97–1/2 inspect&clean cylinder block rg5796 –un–05dec97 tap for head mounting holes in block note: all components (including piston cooling orifices), coolant gallery plugs&oil gallery plugs must be removed from the cylinder block for inspection and cleaning. refer to the proper group for removal of all external&internal mounted components. 1. use d17015br o-ring bore cleaning brush/an equivalent brush to thoroughly clean all debris from cylinder liner o-ring bores. 2. remove cylinder head locating dowels, if not previously removed. clean out all threaded holes for cylinder head mounting cap screws in top deck of cylinder block. use jdg681 tap/an equivalent 9/16-12 unc-2a tap approximately 88.9 mm (3.5 in.) long. use compressed air to remove any debris/fluid which may be present in the cap screw hole. important: if cylinder block is cleaned in a hot tank, be sure to remove any aluminum parts. aluminum parts can be damaged or destroyed by hot tank solutions. remove all serial number plates. continued on next page ctm86 (20mar01) 02-030-31 powertech? 8.1 l diesel engines — base engine 032001 pn=181 cylinder block, liners, pistons,&rods repair&adjustment 02 030 32 rg,rg34710,1134 –19–23oct97–2/2 rg7142 –un–05dec97 measuring liner flange counterbore depth in block a—liner flange counterbore depth b—top deck of cylinder block c—liner support flange 3. clean block thoroughly using cleaning solvent, pressure steam,/a hot tank. 4. inspect liner support flange (c) for burrs. if burrs are present, use a small half-moon file&lightly file (in a circular motion) burr off at approximately a 60° angle. do not let file hit top deck of cylinder block (b) while filing. note: do not file liner support flange excessively. excess filing can damage liner support flange and allow an improper liner fit. thoroughly clean all filings from cylinder block. 5. measure liner flange counterbore depth (a) in block and compare with specification given below. specification cylinder block flange counterbore—depth 11.913—11.963 mm (0.469—0.471 in.) carefully inspect block for cracks/any other physical damage. if a cracked block is suspected, pressure-test the block. a procedure for pressure testing is outlined in fos (fundamentals of service) manual-engines. replace block if there is evidence of a crack/physical damage. ctm86 (20mar01) 02-030-32 powertech? 8.1 l diesel engines — base engine 032001 pn=182 cylinder block, liners, pistons,&rods repair&adjustment 02 030 33 rg,rg34710,1135 –19–23oct97–1/1 measure cylinder block refer to the appropriate groups for a more detailed description of the features being measured. compare measurements with specifications given below. 1. assemble&measure main&thrust bearing bores. compare measurements with specifications given below: specification crankshaft main bearing—bore id without bearing 101.651—101.67 mm (4.0020—4.0030 in.) . surface width 36.28—36.78 mm (1.428—1.448 in.) . crankshaft thrust bearing— bore id without bearing 101.651—101.67 mm (4.0020—4.0030 in.) surface width (no. 5 main) 37.44—37.54 mm (1.474—1.478 in.) overall cap width 41.81—42.31 mm (1.646—1.666 in.) if any main/thrust bearing cap assembled i.d. is not within specification, blank (generic) bearing caps are available&must be line bored to specification by a qualified machine shop. see main bearing cap line bore specifications in group 040. 2. measure camshaft follower bore diameter at all bore locations. specification camshaft follower—bore id in block 17.384—17.440 mm (0.6845—0.6865 in.) . follower od (new) 17.33—17.35 mm (0.682—0.683 in.) . follower-to-bore clearance . 0.114 mm (0.0045 in.) if any one camshaft follower bore is not within specification, install a new cylinder block. 3. measure camshaft bore diameter at all locations and record readings. compare measurements with specifications given in chart below: specification camshaft bushing—installed id 67.076—67.102 mm (2.6408—2.6418 in.) . bushing bore in block 69.987—70.013 mm (2.7554—2.7564 in.) minimum runout of bore in block 0.038 mm (0.0015 in.) bushing-to-journal clearance 0.0063—0.115 mm (0.0025—0.0045 in.) . if camshaft bushing bore diameter in block is more than specified, install a new cylinder block. important: the centerline of the main bearing bore-to-top deck of cylinder block must be 352.35—352.50 mm (13.872—13.878 in.). if not, replace cylinder block. 4. measure cylinder block top deck flatness using d05012st precision straightedge&feeler gauge and compare to following specifications. resurface as required. specification cylinder block top deck— maximum out-of-flat 0.10 mm (0.004 in.) over entire length/width . straightness 0.025 mm (0.001 in.) per any 305 mm (12.0 in) of length maximum wave depth . 2.0 micrometers (79 micro-inch) main bearing bore centerline-to-top deck distance 352.35—352.50 mm (13.872—13.878 in.) ctm86 (20mar01) 02-030-33 powertech? 8.1 l diesel engines — base engine 032001 pn=183 cylinder block, liners, pistons,&rods repair&adjustment 02 030 34 rg,rg34710,1136 –19–23oct97–1/1 install piston cooling orifices&gallery plugs rg10211 –un–18jun99 piston cooling orifices in block a—piston cooling orifices 1. use a soft wire&compressed air to clean orifices. replace if condition is questionable. important: a piston cooling orifice failure could cause damage to pistons, piston pins, rod pin bushings,&liners. if a piston cooling orifice is left out, low/no oil pressure will result. 2. install all six (four shown) piston cooling orifices (a) and tighten to specifications. specification piston cooling orifice into cylinder block—torque . 11 n?m (97 lb-in.) (8 lb-ft) 3. install new oil&coolant gallery plugs as required, if removed. rg,rg34710,1137 –19–23oct97–1/1 recheck cylinder liner standout note: if a new liner assembly is being installed in a new or used cylinder block, liner height must be checked. be sure liner bore in cylinder block&top deck of block are clean. install liners without packing. secure with cap screws and washers&measure liner standout. see measure cylinder liner standout (height above block) earlier in this group. liner shims may be used to bring standout within specification. see install liner shims—if required later in this group. ctm86 (20mar01) 02-030-34 powertech? 8.1 l diesel engines — base engine 032001 pn=184 cylinder block, liners, pistons,&rods repair&adjustment 02 030 35 rg,rg34710,1138 –19–17may99–1/1 install liner shims—if required rg4728 –un–04may89 liner shims if the liner flange thickness is within specification, but recorded standout was no more than 0.08 mm (0.003 in.) below top deck of block, install liner shims on bottom of liner flange. liner shim thickness is as follows: specification cylinder liner shim—thickness 0.05 mm (0.002 in.) a maximum of two liner shims may be used per cylinder, as required. shims have tangs in the i.d. to help hold them in place against bottom of liner flange during liner installation. 1. make sure counterbore in block is clean&free of burrs. install liner(s),&shim(s), in block bore without o-rings. secure liners with cap screws&washers as done previously. tighten cap screws to 68 n?m (50 lb-ft). liner standout should be within the following range but must not exceed 0.127 mm (0.005 in.) after shim installation. specification cylinder liners—standout (height above block) 0.051—0.127 mm (0.002—0.005 in.) . 2. measure liner standout again at 1, 5, 7,&11 o’clock positions. record measurements. if standout is still not within specification, remove liner and determine cause. if standout is within specification, proceed to next step. ctm86 (20mar01) 02-030-35 powertech? 8.1 l diesel engines — base engine 032001 pn=185 cylinder block, liners, pistons,&rods repair&adjustment 02 030 36 rg,rg34710,1139 –19–23oct97–1/2 install packing on cylinder liner and o-rings in block rg3826 –un–04dec97 cylinder liner seals a—o-ring b—o-ring c—cylinder block important: do not use oil on cylinder liner packing/o-rings. oil can cause the red packing to swell, which squeezes liner&could possibly cause a scored piston. 1. pour ar54749 soap lubricant into a suitable container. 2. dip new packings&o-rings in soap before installation. do not leave packings/o-ring in soap to soak. 3. install the black viton o-ring (a) in the lower o-ring groove in the cylinder block (c). 4. install the red silicone o-ring (b) in the upper o-ring groove in the cylinder block. rg,rg34710,1139 –19–23oct97–2/2 rg3827 –un–04dec97 a—square neoprene packing installing cylinder liner packing b—cylinder liner 5. turn cylinder liner (b) upside-down&install the square neoprene packing (a) over outside of liner. 6. slide packing down firmly against second shoulder on liner. note: make sure the square packing is not twisted. 7. coat the liner packing sealing area of the cylinder liner and block o-rings with liquid soap. ctm86 (20mar01) 02-030-36 powertech? 8.1 l diesel engines — base engine 032001 pn=186 cylinder block, liners, pistons,&rods repair&adjustment 02 030 37 rg,rg34710,1140 –19–23oct97–1/2 install cylinder liner in block rg2772 –un–04dec97 installing cylinder liners in block important: install cylinder liners into same cylinder block bore as removed. do not scuff the liner packing across the upper counterbore. pitted/eroded liners that meet reuse guidelines should be rotated 90° from their removed position. see visually inspect cylinder liners earlier in this group for reuse guidelines. 1. install liner in block bore with manufacturing data code (stamped on flange) toward front of engine, unless liner o.d. is pitted/eroded. if liner o.d. is pitted/eroded, but still within acceptable service limits, rotate liner 90° from it’s removed position. pitted sections of the liner should be facing the front/rear of engine. 2. a resistance will be felt when cylinder liner is aligned in pilot bore. 3. using only the pressure of both palms, the cylinder liner should drop to a point nearly flush with upper flange of the cylinder liner&cylinder block. continued on next page ctm86 (20mar01) 02-030-37 powertech? 8.1 l diesel engines — base engine 032001 pn=187 cylinder block, liners, pistons,&rods repair&adjustment 02 030 38 rg,rg34710,1140 –19–23oct97–2/2 rg6092 –un–27jan92 seating cylinder liners in block 4. finish seating cylinder liners using a clean, hardwood block&hammer. 5. gently tap hardwood block over top of cylinder liner with mallet. note: cylinder liner will protrude over top of cylinder block more than normal due to uncompressed packings&o-rings. important: if you suspect a packing may have sheared/displaced during liner installation, remove&examine the liner&packing assembly. if no damage is found, check packings for proper position. resoap packings and reinstall liner assembly. 6. hold liners in place with large flat washers&cap screws. turn cap screws snug but do not tighten. 7. clean cylinder liner bores with waterless hand cleaner after installation. wipe dry with clean towels. 8. apply clean engine oil to liner bores immediately to prevent corrosion. dpsg,ouo1004,886 –19–17may99–1/6 install piston&connecting rod rg9617 –un–02dec98 connecting rods a—tongue&groove rod (earlier engines) b—precision joint? rod (later engines) 1. earlier engines have the traditional tongue-and-groove joint between the connecting rod&cap (a). later engines have the precision joint? rod&cap (b). installation of the different rods is similar, with differences noted in the following instructions. important: do not mix tongue-and-groove rods and precision joint? rods in the same engine. see parts catalog for recommendations. precision joint is a trademark of deere & company ctm86 (20mar01) 02-030-38 powertech? 8.1 l diesel engines — base engine 032001 pn=188 continued on next page cylinder block, liners, pistons,&rods repair&adjustment 02 030 39 dpsg,ouo1004,886 –19–17may99–2/6 rg5239 –un–05dec97 installing piston&connecting rod a—piston pin b—piston c—connecting rod d—snap rings (2 used) e—oil control ring with expander ring f—compression rings important: piston must be installed on same connecting rod from which they were removed&new piston pin snap rings must be used. if a new piston&liner assembly is to be installed, do not remove piston from liner. push piston out of liner bottom only far enough to install piston pin. 2. lubricate piston pin (a)&bushing with clean engine oil. 3. install piston pin through piston (b)&connecting rod (c). be sure “front” of rod aligns with arrow or “front” of piston. 4. install new piston pin snap rings (d) in grooves. make certain snap rings have expanded in grooves of piston. note: full keystone compression ring (one “pip” mark) goes in top piston ring groove. half keystone ring (two “pip”/“top” marks) goes in second ring groove of piston.“pip” mark(s) on no. 1&no. 2 compression rings must face top of piston. ks piston rings are color coded. the no. 1 ring is blue, no. 2 is pink&no. 3 is orange. the expander ring is orange. 5. use the jde93 ring expander to install oil control ring with expander ring (e)&then compression rings. note: new rings are furnished with the correct end gap, therefore, fitting to the liner is not necessary. continued on next page ctm86 (20mar01) 02-030-39 powertech? 8.1 l diesel engines — base engine 032001 pn=189 cylinder block, liners, pistons,&rods repair&adjustment 02 030 40 dpsg,ouo1004,886 –19–17may99–3/6 rg10050 –un–21may99 position of piston ring gaps rg5816 –un–05dec97 installing piston in cylinder liners a—top of piston b—top compression ring gap c—oil control ring gap d—expander ring gap e—bottom compression ring gap f—front of engine 6. stagger ring gaps on piston as shown, with gap of top ring facing the front of the engine. note: if crankshaft was removed, see install main bearings&crankshaft in group 040. 7. coat piston, liners&i.d. of jde96 piston ring compres*** with clean engine oil. 8. carefully place ring compres*** with piston&rod over liner. important: be sure crankshaft journals&liner walls are not damaged when installing piston&rod in liner. note: be sure the word “front” on piston&rod face toward the front of the engine. 9. with piston centered in ring compres***&rings staggered correctly, push piston into liner as shown. continued on next page ctm86 (20mar01) 02-030-40 powertech? 8.1 l diesel engines — base engine 032001 pn=190 cylinder block, liners, pistons,&rods repair&adjustment 02 030 41 dpsg,ouo1004,886 –19–17may99–4/6 rg10209 –un–18jun99 installing connecting rod caps with bearing inserts rg10215 –un–23jun99 stamped numbers a—connecting rod caps b—bearing inserts c—stamped numbers 10. apply clean engine oil to bearing inserts (b) and matching crankshaft rod journals. important: on precision joint? rods, make sure cap is properly aligned on rod with interlocking surfaces sealing tightly and edges aligned. do not reverse cap on rod. match pads on side of rod&cap. when installing caps, make sure stamped numbers (c) on rod&cap are positioned on the same side. 11. install connecting rod caps (a). precision joint is a trademark of deere & company continued on next page ctm86 (20mar01) 02-030-41 powertech? 8.1 l diesel engines — base engine 032001 pn=191 cylinder block, liners, pistons,&rods repair&adjustment 02 030 42 dpsg,ouo1004,886 –19–17may99–5/6 rg4375 –un–05dec97 cap screw in rod cap (tightened first) a—cap screw (tighten first) important: never use connecting rod cap screws more than once for final engine assembly. once rod cap screws have been tightened to final torque-turn specifications, they must not be reused for another final assembly. 12. dip new cap screws&washers in clean engine oil. make sure bore threads&all threads on cap screws are thoroughly oiled. important: do not use pneumatic wrenches to install connecting rod cap screws. doing so may damaged threads. use speed-handle wrench instead. 13. on tongue-and-groove connecting rods: initially, tighten cap screw (a) closest to piston end to specifications. next, tighten the other cap screw. feel rod-to-cap joint to check for proper alignment. specification tongue-and-groove connecting rod cap screw—initial torque . 27 n?m (20 lb-ft) secondly, tighten all cap screws to the following 眉山洪雅县康明斯发动机用滤芯网上商城,丹东东港卡特320BL挖掘机配件价格查询中心,北京平谷9Y-4469卡特滤清器谁知道哪里有卖?,内蒙古自治呼伦贝尔额尔古纳FGWilson发电机更多优质配件纯正配件,贵阳南明卡特320D电喷喷油器销售中心,临沂平邑县强鹿发动机喷油泵认准指定代理商,资阳乐至县帕金斯1606柴油机喷油器网上商城,牡丹江宁安perkins发动机配件最新报价,沈阳苏家屯珀金斯发动机气缸垫电话多小?,银川永宁县CAT7W-8405130-5469原厂专卖,宁波宁海县卡特滤芯382-0664438-53联系方式?,r500574 3 7800 - 7807 r501390 15 1600 - 1671 r500320 16 2300 - 2303 r500574 3 7800 - 7809 r501390 15 1600 - 1673 r500320 13 2300 - 2303b r500574 3 7800 - 7811 r501390 15 1600 - 1675 r500320 18 2300 - 2303d r500574 20 9700 - 9713 r501390 15 1600 - 1677 r500320 16 2300 - 2305 r500588 12 9600 - 9605 r501390 15 1600 - 1679 r500320 13 2300 - 2305b r500612 7800 - 7807 r501390 15 1600 - 1681 r500320 18 2300 - 2305d r500612 11 9700 - 9713 r501390 15 1600 - 1683 r500320 16 2300 - 2307 r500616 1 2400 - 2407 r501390 15 1600 - 1685 r500320 16 2300 - 2309 r500672 2 1500 - 1509 r501390 15 1600 - 1687 r500320 16 2300 - 2311 r501050 9 3900 - 3903 r501390 15 1600 - 1689 r500320 16 2300 - 2313 r501137 7 5200 - 5205 r501390 15 1600 - 1691 r500320 16 2300 - 2315 r501137 17 5200 - 5205 r501390 15 1600 - 1693 r500320 16 2300 - 2317 r501137 7 5200 - 5207 r501390 15 1600 - 1695 r500320 16 2300 - 2319 r501137 7 5200 - 5209 r501390 15 1600 - 1697 r500320 16 2300 - 2321 r501137 7 9700 - 9705 r501390 15 1600a - 1603 r500320 16 2300 - 2323 r501137 7 9700 - 9707 r501390 15 1600a - 1605 r500320 16 2300 - 2325 r501137 17 9700 - 9707 r501390 15 1600a - 1607 r500320 16 2300 - 2325b r501149 17 2300 - 2303b r501390 15 1600a - 1609 r500320 13 2300 - 2327 r501149 17 2300 - 2305b r501390 15 1600a - 1611 r500320 16 2300 - 2327b r501175 6 1400 - 1404 r501390 15 1600a - 1613 r500320 16 2300 - 2327d r501244 5 3000 - 3005 r501390 15 1600a - 1615 r500320 13 2300 - 2329 r501244 5 3000 - 3009 r501390 15 1600a - 1617 r500320 16 2300 - 2329b r501266 1 2400 - 2427 r501390 15 1600a - 1619 r500320 16 2300 - 2329d r501266 1 2400 - 2434 r501390 15 1600a - 1621 r500320 13 2300 - 2331 r501292 12 1100 - 1101 r501390 15 1600a - 1623 r500320 16 2300 - 2331b r501309 11 7700 - 7703 r501390 15 1600a - 1625 r500320 13 2300 - 2333 r501309 11 7700 - 7705 r501390 15 1600a - 1627 r500320 18 2300 - 2333b r501309 11 7700 - 7713 r501390 15 1600a - 1629 r500320 16 2300 - 2333d r501380 3 4800 - 4803 r501390 15 1600a - 1631 r500320 13 2300 - 2335 r501390 15 1600 - 1601b r501390 15 1600a - 1633 r500320 16 2300 - 2335b r501390 15 1600 - 1601d r501528 1 1500 - 1509 r500320 13 2300 - 2339 r501390 15 1600 - 1601f r501537 33 5900 - 5905 r500320 13 2300 - 2341 r501390 15 1600 - 1601h r501537 35 5900 - 5907 r500320 13 2300 - 2343 r501390 15 1600 - 1603 r501561 4 1300 - 1301 r500320 13 2300 - 2345 r501390 15 1600 - 1605 r501561 4 1300 - 1302 r500320 13 2300 - 2347 r501390 15 1600 - 1607 r501561 4 1300 - 1303 r500320 13 2300 - 2349 r501390 15 1600 - 1609 r501561 4 1300 - 1306 r500320 13 2300 - 2351 r501390 15 1600 - 1611 r501561 4 1300 - 1309 r500320 1 2400 - 2408 r501390 15 1600 - 1613 r501561 4 1300 - 1312 r500320 1 2400 - 2409 r501390 15 1600 - 1615 r501561 4 1300 - 1313 r500320 1 2400 - 2410 r501390 15 1600 - 1617 r501566 5 4800 - 4803 r500320 1 2400 - 2411 r501390 15 1600 - 1619 r501618 3 1500 - 1510 r500320 1 2400 - 2412 r501390 15 1600 - 1621 r501632 22 3500 - 3503 r500320 1 2400 - 2413 r501390 15 1600 - 1623 r502026 3 7700 - 7703 r500320 1 2400 - 2417 r501390 15 1600 - 1625 r502026 3 7700 - 7705 r500320 1 2400 - 2418 r501390 15 1600 - 1627 r502026 3 7700 - 7713 r500320 1 2400 - 2419 r501390 15 1600 - 1629 r502026 20 9900 - 9909 r500320 1 2400 - 2423 r501390 15 1600 - 1631 r502027 3 3700 - 3701 r500320 1 2400 - 2424 r501390 15 1600 - 1633 r502027 10 5100 - 5104 r500320 1 2400 - 2425 r501390 15 1600 - 1635 r502027 44 9900 - 9909 r500320 1 2400 - 2430 r501390 15 1600 - 1637 r502044 16 7800 - 7803 r500320 1 2400 - 2431 r501390 15 1600 - 1639 r502044 16 7800 - 7805 r500320 1 2400 - 2432 r501390 15 1600 - 1641 r502045 11 7800 - 7809 r500320 1 2400 - 2433 r501390 15 1600 - 1643 r502045 11 7800 - 7811 r500320 1 2400 - 2437 r501390 15 1600 - 1645 r502046 11 7800 - 7807 r500320 8 9700 - 9727 r501390 15 1600 - 1647 r502052 12 2000 - 2003 r500387 1 5000 - 5001 r501390 15 1600 - 1649 r502079 3 2400 - 2408 r500387 22 9900 - 9909 r501390 15 1600 - 1651 r502079 3 2400 - 2409 r500488 10 9600 - 9603 r501390 15 1600 - 1653 r502079 3 2400 - 2410 r500488 10 9600 - 9605 r501390 15 1600 - 1655 r502079 3 2400 - 2411 r500488 10 9600 - 9607 r501390 15 1600 - 1657 r502079 3 2400 - 2412 r500488 10 9600 - 9609 r501390 15 1600 - 1659 r502079 3 2400 - 2413 9995-14 powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) pc2875 (17-dec-02) pn=670 p r o o f p r o o f powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) numerical index - continued part no. grid key page part no. grid key page part no. grid key page r502079 3 2400 - 2417 r502171 11 1600a - 1605 r502172 6 1600a - 1603 r502079 3 2400 - 2418 r502171 11 1600a - 1607 r502172 6 1600a - 1605 r502079 3 2400 - 2419 r502171 11 1600a - 1609 r502172 6 1600a - 1607 r502079 3 2400 - 2423 r502171 11 1600a - 1611 r502172 6 1600a - 1609 r502079 3 2400 - 2424 r502171 11 1600a - 1613 r502172 6 1600a - 1611 r502079 3 2400 - 2425 r502171 11 1600a - 1615 r502172 6 1600a - 1613 r502079 3 2400 - 2430 r502171 11 1600a - 1617 r502172 6 1600a - 1615 r502079 3 2400 - 2431 r502171 11 1600a - 1619 r502172 6 1600a - 1617 r502079 3 2400 - 2432 r502171 11 1600a - 1621 r502172 6 1600a - 1619 r502079 3 2400 - 2433 r502171 11 1600a - 1623 r502172 6 1600a - 1621 r502079 3 2400 - 2437 r502171 11 1600a - 1625 r502172 6 1600a - 1623 r502079 2 7400 - 7410 r502171 11 1600a - 1627 r502172 6 1600a - 1625 r502079 10 9700 - 9727 r502171 11 1600a - 1629 r502172 6 1600a - 1627 r502124 10 1100 - 1101 r502171 11 1600a - 1631 r502172 6 1600a - 1629 r502171 11 1600 - 1601b r502171 11 1600a - 1633 r502172 6 1600a - 1631 r502171 11 1600 - 1601d r502172 6 1600 - 1601b r502172 6 1600a - 1633 r502171 11 1600 - 1601f r502172 6 1600 - 1601d r502173 7 1600 - 1601b r502171 11 1600 - 1601h r502172 6 1600 - 1601f r502173 7 1600 - 1601d r502171 11 1600 - 1603 r502172 6 1600 - 1601h r502173 7 1600 - 1601f r502171 11 1600 - 1605 r502172 6 1600 - 1603 r502173 7 1600 - 1601h r502171 11 1600 - 1607 r502172 6 1600 - 1605 r502173 7 1600 - 1603 r502171 11 1600 - 1609 r502172 6 1600 - 1607 r502173 7 1600 - 1605 r502171 11 1600 - 1611 r502172 6 1600 - 1609 r502173 7 1600 - 1607 r502171 11 1600 - 1613 r502172 6 1600 - 1611 r502173 7 1600 - 1609 r502171 11 1600 - 1615 r502172 6 1600 - 1613 r502173 7 1600 - 1611 r502171 11 1600 - 1617 r502172 6 1600 - 1615 r502173 7 1600 - 1613 r502171 11 1600 - 1619 r502172 6 1600 - 1617 r502173 7 1600 - 1615 r502171 11 1600 - 1621 r502172 6 1600 - 1619 r502173 7 1600 - 1617 r502171 11 1600 - 1623 r502172 6 1600 - 1621 r502173 7 1600 - 1619 r502171 11 1600 - 1625 r502172 6 1600 - 1623 r502173 7 1600 - 1621 r502171 11 1600 - 1627 r502172 6 1600 - 1625 r502173 7 1600 - 1623 r502171 11 1600 - 1629 r502172 6 1600 - 1627 r502173 7 1600 - 1625 r502171 11 1600 - 1631 r502172 6 1600 - 1629 r502173 7 1600 - 1627 r502171 11 1600 - 1633 r502172 6 1600 - 1631 r502173 7 1600 - 1629 r502171 11 1600 - 1635 r502172 6 1600 - 1633 r502173 7 1600 - 1631 r502171 11 1600 - 1637 r502172 6 1600 - 1635 r502173 7 1600 - 1633 r502171 11 1600 - 1639 r502172 6 1600 - 1637 r502173 7 1600 - 1635 r502171 11 1600 - 1641 r502172 6 1600 - 1639 r502173 7 1600 - 1637 r502171 11 1600 - 1643 r502172 6 1600 - 1641 r502173 7 1600 - 1639 r502171 11 1600 - 1645 r502172 6 1600 - 1643 r502173 7 1600 - 1641 r502171 11 1600 - 1647 r502172 6 1600 - 1645 r502173 7 1600 - 1643 r502171 11 1600 - 1649 r502172 6 1600 - 1647 r502173 7 1600 - 1645 r502171 11 1600 - 1651 r502172 6 1600 - 1649 r502173 7 1600 - 1647 r502171 11 1600 - 1653 r502172 6 1600 - 1651 r502173 7 1600 - 1649 r502171 11 1600 - 1655 r502172 6 1600 - 1653 r502173 7 1600 - 1651 r502171 11 1600 - 1657 r502172 6 1600 - 1655 r502173 7 1600 - 1653 r502171 11 1600 - 1659 r502172 6 1600 - 1657 r502173 7 1600 - 1655 r502171 11 1600 - 1661 r502172 6 1600 - 1659 r502173 7 1600 - 1657 r502171 11 1600 - 1663 r502172 6 1600 - 1661 r502173 7 1600 - 1659 r502171 11 1600 - 1665 r502172 6 1600 - 1663 r502173 7 1600 - 1661 r502171 11 1600 - 1667 r502172 6 1600 - 1665 r502173 7 1600 - 1663 r502171 11 1600 - 1669 r502172 6 1600 - 1667 r502173 7 1600 - 1665 r502171 11 1600 - 1671 r502172 6 1600 - 1669 r502173 7 1600 - 1667 r502171 11 1600 - 1673 r502172 6 1600 - 1671 r502173 7 1600 - 1669 r502171 11 1600 - 1675 r502172 6 1600 - 1673 r502173 7 1600 - 1671 r502171 11 1600 - 1677 r502172 6 1600 - 1675 r502173 7 1600 - 1673 r502171 11 1600 - 1679 r502172 6 1600 - 1677 r502173 7 1600 - 1675 r502171 11 1600 - 1681 r502172 6 1600 - 1679 r502173 7 1600 - 1677 r502171 11 1600 - 1683 r502172 6 1600 - 1681 r502173 7 1600 - 1679 r502171 11 1600 - 1685 r502172 6 1600 - 1683 r502173 7 1600 - 1681 r502171 11 1600 - 1687 r502172 6 1600 - 1685 r502173 7 1600 - 1683 r502171 11 1600 - 1689 r502172 6 1600 - 1687 r502173 7 1600 - 1685 r502171 11 1600 - 1691 r502172 6 1600 - 1689 r502173 7 1600 - 1687 r502171 11 1600 - 1693 r502172 6 1600 - 1691 r502173 7 1600 - 1689 r502171 11 1600 - 1695 r502172 6 1600 - 1693 r502173 7 1600 - 1691 r502171 11 1600 - 1697 r502172 6 1600 - 1695 r502173 7 1600 - 1693 r502171 11 1600a - 1603 r502172 6 1600 - 1697 r502173 7 1600 - 1695 powertech 12.5l 6125hf070 engine (waterloo) (, esn 030000- ) pc2875 (17-dec-02) 9995-15 pn=671 p r o o f p r o o f powertech 12.5l 6125hf070 engine (waterloo) (esn 030000- ) numerical index - continued part no. grid key page part no. grid key page part no. grid key page r502173 7 1600 - 1697 r502703 10 1600 - 1633 r503782 23 2300 - 2307 r502173 7 1600a - 1603 r502703 10 1600 - 1635 r503782 23 2300 - 2309 r502173 7 1600a - 1605 r502703 10 1600 - 1637 r503782 23 2300 - 2311 r502173 7 1600a - 1607 r502703 10 1600 - 1639 r503782 23 2300 - 2313 r502173 7 1600a - 1609 r502703 10 1600 - 1641 r503782 23 2300 - 2315 r502173 7 1600a - 1611 r502703 10 1600 - 1643 r503782 23 2300 - 2317 r502173 7 1600a - 1613 r502703 10 1600 - 1645 r503782 23 2300 - 2319 r502173 7 1600a - 1615 r502703 10 1600 - 1647 r503782 23 2300 - 2321 r502173 7 1600a - 1617 r502703 10 1600 - 1649 r503782 23 2300 - 2323 r502173 7 1600a - 1619 r502703 10 1600 - 1651 r503782 23 2300 - 2325 r502173 7 1600a - 1621 r502703 10 1600 - 1653 r503782 23 2300 - 2325b r502173 7 1600a - 1623 r502703 10 1600 - 1655 r503782 23 2300 - 2327b r502173 7 1600a - 1625 r502703 10 1600 - 1657 r503782 23 2300 - 2327d r502173 7 1600a - 1627 r502703 10 1600 - 1659 r503782 23 2300 - 2329b r502173 7 1600a - 1629 r502703 10 1600 - 1661 r503782 23 2300 - 2331b r502173 7 1600a - 1631 r502703 10 1600 - 1663 r503782 23 2300 - 2333d r502173 7 1600a - 1633 r502703 10 1600 - 1665 r503782 23 2300 - 2335b r502306 1 9900 - 9901 r502703 10 1600 - 1667 r503823 6 2300 - 2311 r502391 7 6200 - 6204 r502703 10 1600 - 1669 r503823 15 2300 - 2311 r502391 7 6200 - 6205 r502703 10 1600 - 1671 r503823 6 2300 - 2321 r502392 10 6200 - 6204 r502703 10 1600 - 1673 r503823 6 2300 - 2331b r502392 10 6200 - 6205 r502703 10 1600 - 1675 r503823 7 2300 - 2333 r502417 1 2400 - 2436 r502703 10 1600 - 1677 r503823 11 2300 - 2333b r502434 2 6200 - 6204 r502703 10 1600 - 1679 r503823 7 2300 - 2339 r502434 2 6200 - 6205 r502703 10 1600 - 1681 r503823 7 2300 - 2347 r502441 17 7700 - 7703 r502703 10 1600 - 1683 r503823 7 2300 - 2349 r502441 18 7700 - 7705 r502703 10 1600 - 1685 r503824 15 4900 - 4903 r502441 18 7700 - 7713 r502703 10 1600 - 1687 r503848 4 7400 - 7410 r502441 21 9900 - 9909 r502703 10 1600 - 1689 r503970 12 5100 - 5104 r502461 1 2400 - 2405 r502703 10 1600 - 1691 r503970 2 9900 - 9907 r502461 6 2400 - 2412 r502703 10 1600 - 1693 r503971 5 5100 - 5103 r502461 1 2400 - 2416 r502703 10 1600 - 1695 r504000 1 5900 - 5905 r502461 6 2400 - 2419 r502703 10 1600 - 1697 r504011 9 5900 - 5905 r502470 21 7700 - 7703 r502703 10 1600a - 1603 r504011 25 5900 - 5907 r502490 1 3500 - 3503 r502703 10 1600a - 1605 r504063 1 6200 - 6206 r502493 30 3500 - 3503 r502703 10 1600a - 1607 r504174 12 5100 - 5103 r502530 21 7700 - 7705 r502703 10 1600a - 1609 r504242 15 5100 - 5103 r502530 21 7700 - 7713 r502703 10 1600a - 1611 r504243 20 5100 - 5103 r502659 17 2300 - 2327 r502703 10 1600a - 1613 r504536 3 6200 - 6206 r502659 17 2300 - 2329 r502703 10 1600a - 1615 r504613 2 2800 - 2801 r502659 17 2300 - 2331 r502703 10 1600a - 1617 r504637 12 9700 - 9711 r502659 17 2300 - 2333 r502703 10 1600a - 1619 r504666 14 5200 - 5207 r502659 17 2300 - 2335 r502703 10 1600a - 1621 r504671 1 2300 - 2303d r502659 17 2300 - 2343 r502703 10 1600a - 1623 r504671 1 2300 - 2305d r502659 17 2300 - 2345 r502703 10 1600a - 1625 r504671 1 2300 - 2307 r502659 17 2300 - 2347 r502703 10 1600a - 1627 r504671 25 2300 - 2307 r502659 17 2300 - 2349 r502703 10 1600a - 1629 r504671 25 2300 - 2309 r502659 17 2300 - 2351 r502703 10 1600a - 1631 r504671 1 2300 - 2311 r502703 10 1600 - 1601b r502703 10 1600a - 1633 r504671 25 2300 - 2311 r502703 10 1600 - 1601d r502703 6 9900 - 9909 r504671 1 2300 - 2313 r502703 10 1600 - 1601f r502704 12 3500 - 3503 r504671 25 2300 - 2313 r502703 10 1600 - 1601h r502705 28 3500 - 3503 r504671 1 2300 - 2315 r502703 10 1600 - 1603 r502753 11 4600 - 4603 r504671 25 2300 - 2315 r502703 10 1600 - 1605 r502767 5 1700 - 1701 r504671 25 2300 - 2317 r502703 10 1600 - 1607 r502767 5 1700 - 1702 r504671 25 2300 - 2319 r502703 10 1600 - 1609 r502861 8 9700 - 9715 r504671 25 2300 - 2321 r502703 10 1600 - 1611 r502862 6 9700 - 9715 r504671 25 2300 - 2323 r502703 10 1600 - 1613 r502884 1 9900 - 9903 r504671 25 2300 - 2325 r502703 10 1600 - 1615 r502884 1 9900 - 9905 r504671 1 2300 - 2327b r502703 10 1600 - 1617 r503311 1 2400 - 2427 r504671 25 2300 - 2327b r502703 10 1600 - 1619 r503311 6 2400 - 2431 r504671 1 2300 - 2329b r502703 10 1600 - 1621 r503312 1 2400 - 2429 r504671 25 2300 - 2329b r502703 10 1600 - 1623 r503312 6 2400 - 2433 r504671 25 2300 - 2331b r502703 10 1600 - 1625 r503312 1 2400 - 2435 r504671 1 2300 - 2333b r502703 10 1600 - 1627 r503312 1 2400 - 2436 r504671 1 2300 - 2335b r502703 10 1600 - 1629 r503400 29 5900 - 5903 r504671 25 2300 - 2335b r502703 10 1600 - 1631 r503714 29 5900 - 5903 r504671 4 2300 - 2336

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska