详细描述

约翰迪尔轮式装载机应用的发动机零件

设备型号

备注

244E

Con Rod (m): R80034, Piston (m): RE30250

624EH

(no special remarks)

544HLL

Piston (m) RE55512, RE505102

544A

Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

644C

Con.Rod (m) R71074 (P/N AR93341)

644J

Piston (m) RE515037 Tier 2 & Tier 3

544G

Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

TC444H

Piston (m) RE55512, RE505102

344E

Large pin

624G

(no special remarks)

624H

Piston (m) RE55512, RE505102

444

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

644C

Con Rod (m) R71074 (P/N AR93341)

724J

Piston (m) RE515037 Tier 2 & Tier 3

444D

Liter designated, Con Rod (m): R80032, Piston (m): RE22678

444HCL

Piston (m) RE521616 Tier 2 & Tier 3

344E

Liter designated

544B

Liter designated

624HLL

Piston (m) RE55512, RE505102

444C

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

644E

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

644G

Piston (m) RE507758 Tier 2 & Tier 3

544E

Liter designated, Con Rod (m): R80032, Piston (m): RE22678

TC444H

Piston (m) RE521616 Tier 2 & Tier 3

444E

(no special remarks)

544C

Liter designated

TC544H

Piston (m) RE55512, RE505102

444D

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

644ER

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

644H

Piston (m) RE507758 Tier 2 & Tier 3

544EH

Liter designated, Con Rod (m): R80032, Piston (m): RE22678

444HCL

Piston (m) RE515037 Tier 2 & Tier 3

444G

(no special remarks)

544D

Liter designated

TC624H

Piston (m) RE55512, RE505102

444CH

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

644G

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

644J

Piston (m) RE507758 Tier 2 & Tier 3

544G

Liter designated, Con Rod (m): R80032, Piston (m): RE22678

TC444H

Piston (m) RE515037 Tier 2 & Tier 3

344G

(no special remarks)

624E

Liter designated

644G

Piston (m) RE521616 Tier 2 & Tier 3

544A

Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

644GH

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

724J

Piston (m) RE507758 Tier 2 & Tier 3

544C

Large pin

444HCL

Piston (m) RE507758 Tier 2 & Tier 3

344G

Liter designated

624EH

Liter designated

644H

Piston (m) RE521616 Tier 2 & Tier 3

444D

Con Rod (m): R80034, Piston (m): RE30250

644B

Con R, od (m) R48315, R53287, R58883, R66926

644G

Piston (m) RE515037 Tier 2 & Tier 3

544B

(no special remarks)

TC444H

Piston (m) RE507758 Tier 2 & Tier 3

444E

Liter designated

624G

Liter designated

644J

Piston (m) RE521616 Tier 2 & Tier 3

444D

Liter designated, Con Rod (m): R80034, Piston (m): RE30250

744E

Late, Con Rod (m): R63959

644H

Piston (m) RE515037 Tier 2 & Tier 3

544C

(no special remarks)

444HCL

Piston (m) RE515037 Tier 2 & Tier 3

444G

Liter designated

644

To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

724J

Piston (m) RE521616 Tier 2 & Tier 3

444D

Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

344H

Piston (m) RE59277, RE505100

644J

Piston (m) RE515037 Tier 2 & Tier 3

544D

(no special remarks)

TC444H

Piston (m) RE515037 Tier 2 & Tier 3

544

O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): T23481

644A

To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

644G

Piston (m) RE515037 Tier 2 & Tier 3

544E

Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

444H

Piston (m) RE55512, RE505102

724J

Piston (m) RE515037 Tier 2 & Tier 3

624E

(no special remarks)

544H

Piston (m) RE55512, RE505102

544

O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481

644D

Con Rod (m) R57303, R67320

644H

Piston (m) RE515037 Tier 2 & Tier 3

544EH

Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

444HCL

Piston (m) RE55512, RE505102

约翰迪尔轮式装载机应用的发动机零件

| 设备型号 | 备注 |

|---|---|

| 244E | Con Rod (m): R80034, Piston (m): RE30250 |

| 624EH | (no special remarks) |

| 544HLL | Piston (m) RE55512, RE505102 |

| 544A | Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310 |

| 644C | Con.Rod (m) R71074 (P/N AR93341) |

| 644J | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544G | Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278 |

| TC444H | Piston (m) RE55512, RE505102 |

| 344E | Large pin |

| 624G | (no special remarks) |

| 624H | Piston (m) RE55512, RE505102 |

| 444 | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 644C | Con Rod (m) R71074 (P/N AR93341) |

| 724J | Piston (m) RE515037 Tier 2 & Tier 3 |

| 444D | Liter designated, Con Rod (m): R80032, Piston (m): RE22678 |

| 444HCL | Piston (m) RE521616 Tier 2 & Tier 3 |

| 344E | Liter designated |

| 544B | Liter designated |

| 624HLL | Piston (m) RE55512, RE505102 |

| 444C | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 644E | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 644G | Piston (m) RE507758 Tier 2 & Tier 3 |

| 544E | Liter designated, Con Rod (m): R80032, Piston (m): RE22678 |

| TC444H | Piston (m) RE521616 Tier 2 & Tier 3 |

| 444E | (no special remarks) |

| 544C | Liter designated |

| TC544H | Piston (m) RE55512, RE505102 |

| 444D | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 644ER | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 644H | Piston (m) RE507758 Tier 2 & Tier 3 |

| 544EH | Liter designated, Con Rod (m): R80032, Piston (m): RE22678 |

| 444HCL | Piston (m) RE515037 Tier 2 & Tier 3 |

| 444G | (no special remarks) |

| 544D | Liter designated |

| TC624H | Piston (m) RE55512, RE505102 |

| 444CH | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 644G | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 644J | Piston (m) RE507758 Tier 2 & Tier 3 |

| 544G | Liter designated, Con Rod (m): R80032, Piston (m): RE22678 |

| TC444H | Piston (m) RE515037 Tier 2 & Tier 3 |

| 344G | (no special remarks) |

| 624E | Liter designated |

| 644G | Piston (m) RE521616 Tier 2 & Tier 3 |

| 544A | Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762 |

| 644GH | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 724J | Piston (m) RE507758 Tier 2 & Tier 3 |

| 544C | Large pin |

| 444HCL | Piston (m) RE507758 Tier 2 & Tier 3 |

| 344G | Liter designated |

| 624EH | Liter designated |

| 644H | Piston (m) RE521616 Tier 2 & Tier 3 |

| 444D | Con Rod (m): R80034, Piston (m): RE30250 |

| 644B | Con R, od (m) R48315, R53287, R58883, R66926 |

| 644G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544B | (no special remarks) |

| TC444H | Piston (m) RE507758 Tier 2 & Tier 3 |

| 444E | Liter designated |

| 624G | Liter designated |

| 644J | Piston (m) RE521616 Tier 2 & Tier 3 |

| 444D | Liter designated, Con Rod (m): R80034, Piston (m): RE30250 |

| 744E | Late, Con Rod (m): R63959 |

| 644H | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544C | (no special remarks) |

| 444HCL | Piston (m) RE515037 Tier 2 & Tier 3 |

| 444G | Liter designated |

| 644 | To ESN 335,845, Block (m): R43310, R45980, R47020, R47110 |

| 724J | Piston (m) RE521616 Tier 2 & Tier 3 |

| 444D | Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278 |

| 344H | Piston (m) RE59277, RE505100 |

| 644J | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544D | (no special remarks) |

| TC444H | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544 | O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): T23481 |

| 644A | To ESN 335,845, Block (m): R43310, R45980, R47020, R47110 |

| 644G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544E | Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278 |

| 444H | Piston (m) RE55512, RE505102 |

| 724J | Piston (m) RE515037 Tier 2 & Tier 3 |

| 624E | (no special remarks) |

| 544H | Piston (m) RE55512, RE505102 |

| 544 | O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481 |

| 644D | Con Rod (m) R57303, R67320 |

| 644H | Piston (m) RE515037 Tier 2 & Tier 3 |

| 544EH | Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278 |

| 444HCL | Piston (m) RE55512, RE505102 |

约翰迪尔 6068T 6.8T 活塞(米) RE59277/RE505100

|

| ||||||||||||||||||||||||||||

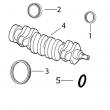

(1)使用机械分离连杆使用TR114083棒螺栓,以及使用TR501124带裂隙分离连杆的棒式螺栓。

(2)将所有R78558带帽螺丝更换为法兰式带帽螺丝TR85363。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)1件组合式密封和穿套;替换TRE59810,RE538097。

(6)与Stanadyne DE10注射泵一起使用。

(7)检查应用程序是否正确使用。

(8)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确的操作。

(9)这些标记号RE59277,RE505100需要使用Ring Set TRE66271。约翰迪尔已经停产

(10)线路连接都是线程化的。

(11)线路连接是一个软管倒钩&一个线程。

(12)线路连接是两个软管倒钩。

(13)连杆R500000。

(14)机器分体式和断裂式分体式连杆都可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHNDEERE 高压油泵型号:

RE506965、RE53785、RE506879、RE506879、RE64241、RE503049、RE505052、SE501237、RE518089、RE506883、RE503051、RE508613、RE502711、SE501237、RE518164、SE501234、RE518167、RE501317、RE506085、RE506084、RE51866、SE501235、SE501234、RE505475、RE539769、RE518088、RE518166、RE503049aftercooled engines (6081a), the turbocharger compres*** discharge air is cooled by routing it through a heat exchanger mounted within the intake manifold. liquid coolant circulates to cool the charged air. on air-to-air aftercooled engines (6081h), the turbocharger compres*** discharge air is cooled by routing it through a heat exchanger (usually mounted in front of radiator) before it enters the intake manifold. this heat exchanger uses no liquid coolant, but relies on air flow to cool the charge air. the camshaft&followers are made of chi, lled iron. the cam lobes are individually flame hardened to provide excellent wear characteristics. spherically ground followers which ride on tapered cam lobes help insure positive follower rotation. the front timing gear train consists of high contact ratio spur gears, allowing for two gear teeth contact at all times. cam followers, push rods,&rocker arm assembly operate intake&exhaust valves. cylinder heads have replaceable inserts&valves,&they have exhaust valve stem seals. the crankshaft is a one-piece, heat treated, dynamically balanced steel forging which rotates in replaceable two-piece main bearings. the main thrust bearing has a flange on each side to reduce crankshaft deflection&to limit end play during high load operation. cylinder liners are of a wet sleeve, flanged, and centrifugally cast design. o-ring type packings are used to seal the connection between cylinder block and liners. liners are induction hardened&can be individually replaced (as a matched piston&liner set). pistons are cast with high-silicone aluminum alloy and have a three-ring configuration. the top two rings are compression rings,&the lower ring is an oil control ring. a double ni-resist ring carrier is cast integrally in the piston to greatly improve the life of the compression ring grooves. a deep “reentrant” combustion chamber design provides maximum combustion efficiency&lower emissions. top of piston is ceramic fiber reinforced to accommodate higher firing pressures generated from higher horsepower output. the highly polished, hardened piston pins are fully-floating&held in position by means of snap rings. spray jets (piston cooling orifices) in cylinder block direct pressure oil to lubricate piston pins and cool pistons. ctm86 (20mar01) 03-120-3 powertech? 8.1 l diesel engines — base engine 032001 pn=347 continued on next page base engine operation 03 120 4 dpsg,rg33894,1 –19–17jun98–2/2 connecting rods are of forged steel&have replaceable bushing&bearing inserts. they are weight controlled (by machining) on both ends to minimize engine vibration. early production engines have the traditional machined joint between the rod and cap. later engines have the non-machined, precision joint? rod&cap. the engine is supplied with lubricating oil by a spur gear pump driven off the rear of the crankshaft. oil is conditioned by a full-flow filter&a housing located on the right side of the engine. oil temperature is limited by an oil cooler located on left side of engine. individual oil cooler&oil filter bypass valves protect the system&insure engine lubrication during times of high restriction; such as cold starts. oil pressure is controlled by a pressure regulating valve located before the main oil gallery. precision joint is a trademark of deere & company ctm86 (20mar01) 03-120-4 powertech? 8.1 l diesel engines — base engine 032001 pn=348 base engine operation 03 120 5 rg,ctm86,g105,6 –19–16sep94–1/4 lubrication system operation rg9765 –un–04dec98 engine lubrication system serial number ( —199,999) a—oil pump f—oil pressure regulating k—connecting rod bearings p—turbocharger lube line b—oil cooler valve l—camshaft thrust washers q—turbocharger oil return c—oil cooler bypass valve g—oil filter base (2 used) r—camshaft followers d—oil filter bypass valve h—crankshaft main bearings m—main oil gallery s—return oil e—oil pressure regulating i—piston cooling orifices n—drilled oil passage t—pressurized oil valve housing j—camshaft bushings o—rocker arm shaft ctm86 (20mar01) 03-120-5 powertech? 8.1 l diesel engines — base engine 032001 pn=349 continued on next page base engine operation 03 120 6 rg,ctm86,g105,6 –19–16sep94–2/4 lubrication system serial number ( —199,999) the engine lubrication system consists of a crank-driven oil pump (a), oil cooler (b), oil filter, oil cooler bypass valve (c), oil filter bypass valve (d), and oil pressure regulating valve (f). oil is drawn up from the sump through the oil pump and on to the oil cooler by way of the oil cooler cover which houses the oil cooler bypass valve. oil proceeds through the oil cooler where it exchanges heat with the engine coolant, unless high restriction is sensed in which case the oil cooler is bypassed. oil goes to the oil filter base (g) which houses the oil filter bypass valve. oil passes through the oil filter (not shown), unless high restriction is sensed in which case the oil filter is bypassed. the oil then moves to the oil pressure regulating valve housing (e) where the regulating valve regulates the main oil gallery (m) pressure&permits excess oil to be returned to the sump. after flowing past the regulating valve, cooled, clean pressurized oil is supplied to the main oil gallery then distributed to the crankshaft main bearings (h)&piston cooling orifices (i) through drilled passages in the cylinder block. the main bearings work to send oil to the camshaft bushings (j) while passages in the crankshaft allow pressurized oil to also lubricate the connecting rod bearings (k). the piston cooling orifices direct oil onto the piston skirt&piston/wrist pin assembly. oil from the front camshaft bushing travels through drilled passages in the camshaft nose to lubricate the camshaft thrust washers (l)&front gear drive train. oil from the rear camshaft bushing feeds through drilled passages (n) in the cylinder block&cylinder head into passages in the rocker arm shaft (o) which lubricate the rocker arms, which in turn provide oil to the other valve train components as well as the camshaft followers (r). some oil is routed from the top of the oil filter base through an external line (p) to the turbocharger&is returned to the cylinder block crankcase through another external line (q). the fuel injection pump is pressure lubricated by way of an external line which taps into the main oil gallery. continued on next page ctm86 (20mar01) 03-120-6 powertech? 8.1 l diesel engines — base engine 032001 pn=350 base engine operation 03 120 7 ctm86 (20mar01) 03-120-7 powertech? 8.1 l diesel engines — base engine 032001 pn=351 base engine operation 03 120 8 rg,ctm86,g105,6 –19–16sep94–3/4 rg11580 –un–01feb01 engine lubrication system serial number (200,000— ) ctm86 (20mar01) 03-120-8 powertech? 8.1 l diesel engines — base engine 032001 pn=352 continued on next page base engine operation 03 120 9 rg,ctm86,g105,6 –19–16sep94–4/4 a—oil pump f—oil pressure regulating k—connecting rod bearings p—turbocharger oil return b—oil cooler valve l—main oil gallery q—camshaft followers c—oil cooler bypass valve g—oil filter base m—drilled oil passage r—return oil d—oil filter bypass valve h—crankshaft main bearings n—rocker arm assemblies s—medium pressure oil e—oil pressure regulating i—piston cooling orifices o—turbocharger lube line t—high pressure oil valve housing j—camshaft bushings lubrication system serial number (200,000— ) the engine lubrication system consists of a crank-driven oil pump (a), oil cooler (b), oil filter, oil cooler bypass valve (c), oil filter bypass valve (d), and oil pressure regulating valve (f). oil is drawn up from the sump through the oil pump and on to the oil cooler by way of the oil cooler cover which houses the oil cooler bypass valve. oil proceeds through the oil cooler where it exchanges heat with the engine coolant, unless high restriction is sensed in which case the oil cooler is bypassed. oil goes to the oil filter base (g) which houses the oil filter bypass valve. oil passes through the oil filter, unless high restriction is sensed in which case the oil filter is bypassed. the oil then moves to the oil pressure regulating valve housing (e) where the regulating valve regulates the main oil gallery (l) pressure&permits excess oil to be returned to the sump. after flowing past the regulating valve, cooled, clean pressurized oil is supplied to the main oil gallery then distributed to the crankshaft main bearings (h)&piston cooling orifices (i) through drilled passages in the cylinder block. the main bearings work to send oil to the camshaft bushings (j) while passages in the crankshaft allow pressurized oil to also lubricate the connecting rod bearings (k). the piston cooling orifices direct oil onto the piston skirt&piston/wrist pin assembly. oil from the front camshaft bushing travels through drilled passages in the camshaft nose to lubricate the camshaft thrust washers (not shown)&front gear drive train. oil from the rear camshaft bushing feeds through drilled passages (m) in the cylinder block&cylinder head into passages in the rocker arm assemblies (n) which lubricate the rocker arms, which in turn provide oil to the other valve train components as well as the camshaft followers (q). some oil is routed from the top of the oil filter base through an external line (o) to the turbocharger&is returned to the cylinder block crankcase through another external line (p). the fuel injection pump is pressure lubricated by way of an external line (not shown) which taps into the main oil gallery. ctm86 (20mar01) 03-120-9 powertech? 8.1 l diesel engines — base engine 032001 pn=353 base engine operation 03 120 10 rg,ctm86,g105,7 –19–16sep94–1/2 cooling system operation rg9766 –un–13jan99 a—to radiator d—thermostats (2 used) g—inlet manifold j—high temperature engine b—coolant bypass tube e—thermostat housing h—engine oil cooler coolant c—coolant pump f—coolant manifold i—low temperature engine coolant ctm86 (20mar01) 03-120-10 powertech? 8.1 l diesel engines — base engine 032001 pn=354 continued on next page base engine operation 03 120 11 rg,ctm86,g105,7 –19–16sep94–2/2 the pressurized cooling system consists of a conventional radiator (a), coolant pump (c), thermostats (d), thermostat housing (e),&cylinder block with coolant cavities. the pump draws coolant from the bottom of the radiator&discharges it through the lower inlet manifold (g) on the left-hand side of the engine block. the inlet directs coolant to the engine oil cooler (h) and provides the cooling capability from the coolant flow around it. coolant passes through the oil cooler cavity&enters the upper coolant manifold (f). at this time, the coolant flow will move in one of three directions. each cylinder is unitized&has a separate flow circuit. the main coolant passage flows through a rectangular port&around the cylinder liner, then exits the block through a vertical passage into the right-hand side of the cylinder head. the second circuit involves flowing coolant from the upper coolant manifold through a small vertical passage into the left-hand side of the cylinder head. the third circuit is called the “directed cooling” system. coolant flows through a small port&into a groove at the top of the cylinder liner. coolant passes around groove in liner,&exits into the vertical passage of the main circuit, then into the right-hand side of the cylinder head. once the coolant is in the cylinder head, all flow is towards the front. coolant passes into the thermostat housing, past the two open thermostats (engine at normal operating temperature),&then returns to the radiator. if the thermostats are closed (as during warm-up periods), coolant is directed back to the pump through the bypass tube (b) to be recirculated. this provides a faster&more uniform warm-up. some coolant is passing through the bypass tube even while the thermostats are open. on air-to-coolant aftercooled engines (6081a), coolant is taken from the upper left cylinder block coolant gallery&routed into an aftercooler where it circulates through the aftercooler core&back to the thermostat housing. coolant circulating through the aftercooler ab***bs heat from the pressurized intake air&carries the heat back to the engine cooling system to be dissipated to the radiator. ctm86 (20mar01) 03-120-11 powertech? 8.1 l diesel engines — base engine 032001 pn=355 base engine operation 03 120 12 rg,rg34710,1072 –19–27apr99–1/2 head gasket joint construction&operation rg6447 –un–26nov97 rg6430 –un–03nov97 a—cylinder head b—cylinder head cap screws c—dowel pins d—cylinder liners e—cylinder block f—gasket body g—fire ring combustion seal h—stainless flange the head gasket joint consist of: ? cylinder head gasket ? cylinder head (a) ? cylinder block (e) ? cylinder liners (d) ? cylinder head cap screws (b) refer to following page for explanation of illustration. ctm86 (20mar01) 03-120-12 powertech? 8.1 l diesel engines — base engine 032001 pn=356 continued on next page base engine operation 03 120 13 rg,rg34710,1072 –19–27apr99–2/2 the head gasket must form an air-tight seal between cylinder liners&cylinder head that can withstand the temperatures&pressures of the combustion process. the gasket must also form a liquid-tight seal between the cylinder head&cylinder block to retain coolant&oil in their respective passages. the gasket is constructed of thin, formed sheets of steel-inserted, non-asbestos material (f). the surface of gasket is treated to improve liquid sealing&anti-stick characteristics. a fire ring combustion seal (g) is located at each cylinder bore and is held in place by a u-shaped stainless steel flange (h). the cylinder head&block must be flat to provide an even clamping pressure over the entire surface of gasket, and must have the proper surface finish to keep gasket material from moving in the joint. dowels (d) are used to properly locate head gasket on block. the cylinder liners must protrude evenly from top of cylinder block the specified amount to provide adequate clamping force on fire ring of each cylinder. the cap screws must be proper length, made of proper material,&be tightened to proper torque in order to provide an adequate clamp local between other joint components. each of the above components contributes to the integrity of the head gasket joint. if any of these components do not conform to specifications, gasket joint may fail resulting in combustion leaks, coolant leaks,/oil leaks. operating conditions such as coolant, oil,&combustion temperatures,&combustion pressures can reduce the ability of the head gasket joint to function properly. failure of head gasket&mating parts may occur when coolant and oil temperatures become excessive,/when abnormally high combustion temperatures&pressures persist. ctm86 (20mar01) 03-120-13 powertech? 8.1 l diesel engines — base engine 032001 pn=357 base engine operation 03 120 14 rg,ctm86,g110,1 –19–16sep94–1/1 air intake&exhaust system operation engine suction draws dust-laden outside air through an air inlet stack into the air cleaner. air is filtered through dry-type primary&secondary (safety) filter elements in the air cleaner canister. clean air travels through the air intake hose to the turbocharger&intake manifold to the engine. exhaust, as it is expelled out the exhaust elbow, drives the turbocharger to deliver a larger quantity of air to meet the engine requirements than what could be delivered under naturally aspirated (non-turbocharged) conditions. on air-to-air aftercooled engines (6081h), the turbocharger compres*** discharge air is routed through a heat exchanger (located in front of radiator) before it enters the engine. the heat exchanger uses no liquid coolant but relies on air flow to cool the charge air. on air-to-coolant aftercooled engines (6081a), the turbocharger compres*** discharge air is routed through the aftercooler. the aftercooler is located in the intake manifold, so the intake air is cooled prior to entering the engine. on engines that don’t have an aftercooler but do have a turbocharger (6081t), the intake air flows directly into the intake manifold from turbocharger. the exhaust air flows out the exhaust manifold. rg,ctm86,g110,3 –19–16sep94–1/1 turbocharger operation r28273 –un–14dec88 a—turbine wheel b—turbine housing c—center housing d—compres*** wheel e—compres*** housing f—shaft the turbocharger, which is basically an air pump that is driven by exhaust gases, allows the engine to produce added power without increasing displacement. turbochargers are precisely matched to meet performance&emission requirements of each specific application. exhaust gases from the engine pass through the turbine housing (b) causing the turbine wheel (a) to rotate before the exhaust gas is discharged to the atmosphere. the turbine wheels mounted on a shaft (f) to drive the compres*** wheel (d) which is also mounted on the shaft. as the compres*** wheel rotates in the compres*** housing (e), an increased volume of (compressed) inlet air is drawn into the housing&delivered to the intake manifold (through an aftercooler/heat exchanger, if so equipped). all rotating components of the turbocharger are lubricated within the center housing (c). ctm86 (20mar01) 03-120-14 powertech? 8.1 l diesel engines — base engine 032001 pn=358 base engine operation 03 120 15 dpsg,rg34710,13 –19–11jan99–1/1 wastegate operation rg9737 –un–12jan99 a—wastegate closed b—wastegate open c—diaphragm d—valve some applications of the 6081 engine have a wastegate actuator (bypass) valve (d) to help control turbine speed&boost at high engine rpm operation. this device is integral to the turbine housing&is diaphragm (c) activated. the wastegate actuator is precisely calibrated and opens a valve to direct some (excess) exhaust gas flow around the turbine wheel to be released from the turbine housing. this limits shaft speed which in turn controls boost pressure. the valve allows the system to develop peak charge-air pressures for maximum engine boost response while eliminating the chance of excessive manifold pressure (over-boost) at high speeds or loads. ctm86 (20mar01) 03-120-15 powertech? 8.1 l diesel engines — base engine 032001 pn=359 base engine operation 03 120 16 rg,ctm61,g110,5 –19–16sep94–1/1 how the turbocharger is lubricated rg4646 –un–29aug94 a—bearing b—thrust plate c—thrust sleeve d—piston ring e—pressure oil f—discharge oil engine oil under pressure from the engine lubrication system is pumped through a passage in the bearing housing&directed to the bearing (a), thrust plate (b), and thrust sleeve (c). oil is sealed from the compres*** and turbine by a piston ring (d) at both ends of bearing housing. the turbocharger contains a single floating bearing. this bearing has clearance between the bearing od&the housing wall as well as clearance between the bearing id and the shaft od. these clearances are lubricated by the oil supply&the bearings are protected by a cushion of oil. discharge oil drains by gravity from the bearing housing to the engine crankcase. ctm86 (20mar01) 03-120-16 powertech? 8.1 l diesel engines — base engine 032001 pn=360 section 04 diagnostics contents page group 150—observable diagnostics&tests about this group of the manual 04-150-1 8.1l - l1 - excessive oil consumption 04-150-2 8.1l - l2 - engine oil pressure low 04-150-6 8.1l - l3 - engine oil pressure high 04-150-8 8.1l - c1 - engine coolant temperature above normal .04-150-9 04 8.1l - c2 - engine coolant temperature below normal 04-150-10 8.1l - c3 - coolant in oil/oil in coolant 04-150-10 test engine compression pressure 04-150-11 check engine cranking speed 04-150-13 check engine oil pressure 04-150-14 check for excessive engine crankcase pressure (blow-by) 04-150-15 check for turbocharger oil seal leak 04-150-16 inspect thermostat&test opening temperature .04-150-17 pressure test cooling system and radiator cap .04-150-18 check for head gasket failures 04-150-20 measure intake manifold pressure (turbo boost) 04-150-24 check for intake&exhaust restrictions 04-150-26 test for intake air leaks 04-150-27 check for exhaust air leaks (turbocharged engines) 04-150-28 test turbocharger wastegate actuator 04-150-29 adjust turbocharger wastegate actuator 04-150-30 ctm86 (20mar01) 04-1 powertech? 8.1 l diesel engines — base engine 032001 pn=1 contents 04 ctm86 (20mar01) 04-2 powertech? 8.1 l diesel engines — base engine 032001 pn=2 group 150 observable diagnostics&tests 04 150 1 dpsg,rg39774,34 –19–27jan99–1/1 about this group of the manual this section of the manual contains necessary information to diagnose some base engine, all lubrication system,&all cooling system problems. this section is divided into two areas: diagnosing malfunctions&testing procedures. the diagnostic malfunctions area is further divided into the following headings, containing the following systems: ? (l) diagnosing lubrication system malfunctions: – l1 - excessive oil consumption – l2 - engine oil pressure low – l3 - engine oil pressure high ? (c) diagnosing cooling system malfunctions – c1 - engine coolant temperature above normal – c2 - engine coolant temperature below normal – c3 - coolant in oil/oil in coolant procedures for diagnosing some of the above symptoms are formatted such that a test/repair is recommended, then based on the results another test or repair is recommended. other symptoms are formatted in a symptom - problem - solution format. in these symptoms, the problems are arranged in the most likely/easiest to check problems first. symptoms arranged in both formats refer to testing procedures in the second part of this section. the second part of this section of the manual contains the following testing procedures: ? base engine testing procedures: – test engine compression pressure – check engine cranking speed ? lubrication system testing procedures: – check engine oil pressure – check for excessive crankcase pressure (blow-by) – check for turbocharger oil seal leak ? cooling system testing procedures: – inspect thermostat&test opening temperature – pressure test cooling system&radiator cap – check for head gasket failures ? air supply&exhaust systems testing procedures: – measure intake manifold pressure (turbo boost) – check for intake&exhaust restrictions – test for intake air leaks – check for exhaust air leaks (turbocharged engines) – test turbocharger wastegate – adjust turbocharger wastegate actuator ctm86 (20mar01) 04-150-1 powertech? 8.1 l diesel engines — base engine 032001 pn=363 observable diagnostics&tests dpsg,rg39774,32 –19–26jan99–1/1 8.1l - l1 - excessive oil consumption 04 150 2 – – –1/1 8.1l - l1 - excessive oil consumption before using this diagnostic procedure: check for too low/too high engine oil level. check for too low viscosity,/coolant/fuel diluted engine oil. check for excessive external oil leaks. – – –1/1 1 oil in coolant check check the coolant for signs of oil. no oil found in coolant: go to 2 oil found in coolant: see c3 - coolant in oil/oil in coolant later in this group. ctm86 (20mar01) 04-150-2 powertech? 8.1 l diesel engines — base engine 032001 pn=364 observable diagnostics&tests 04 150 3 – – –1/1 2 crankcase breather tube check rg9720 –un–04dec98 a restricted crankcase breather tube (a) can cause excessive pressure to build up and force oil into the combustion chamber. check the breather tube to make sure there is no blockage, no kinks,&no restrictions. breather tube not restricted: go to 3 restriction found in breather tube: remove restriction or replace breather tube and retest. ctm86 (20mar01) 04-150-3 powertech? 8.1 l diesel engines — base engine 032001 pn=365 observable diagnostics&tests 04 150 4 – – –1/1 3 excessive crankcase pressure check check for excessive crankcase pressure. see check for excessive engine crankcase pressure (blow-by) later in this group. no fumes&no dripping oil observed: go to 4 excessive fumes or dripping oil observed; appears to be caused by boost pressure (if equipped with turbocharger): check the turbocharger, repair/replace as needed. see turbocharger failure analysis in section 02, group 080 of this manual. excessive fumes or dripping oil observed; does not appear to be caused by boost pressure (if equipped with turbocharger): excessive blow-by, not caused by boost pressure is most likely caused by faulty piston rings/cylinder liners not providing an adequate combustion seal. perform a compression test to verify this is the case. see test engine compression pressure later in this group. – – –1/1 4 turbocharger oil seal leak check note: this check is not needed for non-turbocharged (“d” engines), for these engines go to 5. check for turbocharger oil seal leaks. see check for turbocharger oil seal leak later in this group. no signs of oil leakage: go to 5 signs of oil leakage present: investigate problems associated with oil leakage as outlined it the test procedure, perform necessary repairs, and retest. ctm86 (20mar01) 04-150-4 powertech? 8.1 l diesel engines — base engine 032001 pn=366 observable diagnostics&tests – – –1/1 5 pistons, rings, cylinder liners check at this point, the most likely cause of the excessive oil consumption is one of the following failures in the pistons, rings, and/or cylinder liners/in the valve guides. check the most likely item as needed. ? oil control rings worn/broken ? scored cylinder liners/pistons ? piston ring grooves excessively worn ? piston rings sticking in ring grooves ? insufficient piston ring tension ? piston ring gaps not staggered ? cylinder liners glazed (insufficient load during engine break-in) ? worn valve guides/stems problem found with pistons, rings, and/or liners/valve guides: repair problem as necessary. 04 150 5 ctm86 (20mar01) 04-150-5 powertech? 8.1 l diesel engines — base engine 032001 pn=367 observable diagnostics&tests 04 150 6 dpsg,rg40854,710 –19–03aug00–1/2 8.1l - l2 - engine oil pressure low symptom problem solution 8.1l - l2 - engine oil pressure low crankcase oil level fill crankcase to proper level. low incorrect oil drain crankcase&refill with proper grade&viscosity oil. see diesel engine oil in section 01, group 002 of this manual. plugged oil filter change oil&oil filter faulty oil pressure switch/sen***/measure engine oil pressure with a oil pressure indicator light/gauge mechanical gauge to verify pressure is low. see check engine oil pressure later in this group. excessive oil temperature remove&inspect engine oil cooler. see remove, inspect, and install engine oil cooler in section 02, group 060 of this manual. 惠州约翰迪尔强鹿3029柴油机气门弹簧多少钱,宜昌约翰迪尔6090柴油机排气门厂家供货,湘西约翰迪尔4045TF机油泵代理,枣庄强鹿进气门R93308批发商,楚雄约翰迪尔RE560752机油冷却器多少钱,南通约翰迪尔4045TF258柴油机配件厂家供货,贵阳约翰迪尔5-854拖拉机发动机配件厂家供货,太原强鹿柴油发电机组进排气门诚信推荐,红河强鹿6068柴油机水泵总成批发商,达州JohnDeere连杆RE500608公司,南充约翰迪尔4045柴油机空气加热器供应商,温州约翰迪尔挖掘机继电器市场报价,铜仁约翰迪尔6068柴油机大修包找哪家,韶关JohnDeereR97490进气门价格,台南强鹿柴油机曲轴齿哪里买,信阳约翰迪尔6068柴油机气门油封价格行情,忻州约翰迪尔柴油机气门锁夹T20077市场报价,汕头约翰迪尔R106831进气门导管一级代理,萍乡johndeere约翰迪尔强鹿柴油发动机启动马达RE523502哪家好,faulty oil pressure regulating valve remove&inspect engine oil pressure regulating valve. see remove, inspect,&install oil pressure regulating valve in section 02, group 060 of this manual. plugged oil pump screen/cracked remove oil pan&clean screen. pick-up tube replace oil intake (pick-up) tube. see remove, inspect, and install oil pump pickup tube in section 02, group 060 of this manual. faulty oil pump remove&inspect engine oil pump. see remove engine oil pump&inspect&clean oil pump in section 02, group 060 of this manual. ctm86 (20mar01) 04-150-6 powertech? 8.1 l diesel engines — base engine 032001 pn=368 continued on next page observable diagnostics&tests dpsg,rg40854,710 –19–03aug00–2/2 symptom problem solution faulty/missing piston cooling check piston cooling orifices. orifice excessive main/connecting rod determine bearing clearance. see bearing clearance check main bearing oil clearance in section 02, group 050 of this manual. 04 150 7 ctm86 (20mar01) 04-150-7 powertech? 8.1 l diesel engines — base engine 032001 pn=369 observable diagnostics&tests 04 150 8 KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE47431 FUEL LINE 1 X NO. 6

2 RE47430 FUEL LINE 1 X NO. 5

3 RE47429 FUEL LINE 1 X NO. 4

4 R120185 BOLT 5 X

R58186 CLAMP 10 X

R120181 STRAP 5 X

R120182 STRAP 5 X

5 RE47428 FUEL LINE 1 X NO. 3

6 RE502930 FUEL LINE 1 X NO. 2

7 RE502929 FUEL LINE 1 X NO. 1

8 R120186 BOLT 2 X

R71212 CLAMP 1 X

R120183 STRAP 1 X

R120184 STRAP 1 X

R59297 HALF CLAMP 2 X

9 R71212 CLAMP 1 X

R59297 HALF CLAMP 2 X

R74030 CLAMP 1 X

R74804 CLAMP 1 X

R120186 BOLT 2 X

R120183 STRAP 1 X

R120184 STRAP 1 X

10 R120185 BOLT 1 X

R59297 HALF CLAMP 2 X

R120183 STRAP 2 X

11 RE55662 ABSORBER 1 X

12 24H1884 WASHER 1 X 13/32" X 13/16" X 0.120"

13 19M7166 CAP SCREW 1 X M10 X 20

14 RE61593 INJECTION NOZZLE 6 X (A) (ROBERT BOSCH)

15 R84472 WASHER 6 X 7.360 X 18.160 X 2 MM (0.290" X 0.715"

X 0.079")

16 R504057 O-RING 6 087550- X

17 RE501970 ADAPTER 1 X

18 R51937 TUBE NUT 1 X

19 AR85519 PLUG 1 X

20 RE500803 FUEL LINE 1 X

21 R79604 TUBE NUT 1 X

(A) 1 ORANGE DOT

1 POINT ORANGE

1 ORANGEFARBENER PUNKT

1 PUNTO ARANCIONE

1 PUNTO ANARANJADO

1 ORANGEFAERGAD PUNKT

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R60277 SNAP RING 1 X X

2 R375R O-RING 1 X X

3 R60279 NUT 1 X X

4 R60278 SNAP RING 1 X X

5 .. NOZZLE HOLDER 1 X X (SUB RE61593)

6 R83720 WASHER 1 X X 1.02 MM (.0402")

R83721 WASHER 1 X X 1.08 MM (.0425")

R83722 WASHER 1 X X 1.12 MM (.0441")

R83723 WASHER 1 X X 1.18 MM (.0465")

R83724 WASHER 1 X X 1.22 MM (.0480")

R83725 WASHER 1 X X 1.28 MM (.0504")

R83726 WASHER 1 X X 1.30 MM (.0512")

R83727 WASHER 1 X X 1.38 MM (.0543")

R83728 WASHER 1 X X 1.42 MM (.0559")

R83729 WASHER 1 X X 1.48 MM (.0583")

R83730 WASHER 1 X X 1.50 MM (.0591")

R83731 WASHER 1 X X 1.58 MM (.0622")

R83732 WASHER 1 X X 1.60 MM (.0630")

R83733 WASHER 1 X X 1.68 MM (.0661")

R83734 WASHER 1 X X 1.70 MM (.0669")

R83735 WASHER 1 X X 1.78 MM (.0701")

R83736 WASHER 1 X X 1.82 MM (.0717")

R83737 WASHER 1 X X 1.88 MM (.0740")

R83738 WASHER 1 X X 1.90 MM (.0748")

R83739 WASHER 1 X X 1.98 MM (.0780")

7 R108699 SPRING 1 X X

8 R108700 SEAT 1 X X

9 R108701 PLATE 1 X X

10 RE42306 INJECTION NOZZLE 1 X X (7 X .240)

11 R127176 NUT 1 X X

12 R84472 WASHER 1 X X

13 RE61593 INJECTION NOZZLE 6 X X (A) (ROBERT BOSCH)

(A) (1) ORANGE DOT

(1) POINT ORANGE

(1) ORANGEFARBENER PUNKT

(1) PUNTO ARANCIONE

(1) PUNTO ANARANJADO

(1) ORANGEFAERGAD PUNKT

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska