详细描述

约翰迪尔集材机应用的发动机零件

设备型号

备注

440

O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

740A

Con Rod (m) R71074 (P/N AR93341)

740G

Piston (m) RE521616 Tier 2 & Tier 3

740 G

High Compression Piston. To ESN 199,999. Tier 1

340D

(no special remarks)

548GII

Piston (m) RE55512, RE505102

748GIII

Piston (m) RE515037 Tier 2 & Tier 3

540A

Small pin, O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, R51451, AR78310

640H

Piston (m) RE527039 Tier 2 & Tier 3

560D

Piston (m) RE515037 Tier 2 & Tier 3

440

Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

740E

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

748G

Piston (m) RE521616 Tier 2 & Tier 3

748 G

High Compression Piston. To ESN 199,999. Tier 1

440C

(no special remarks)

548GIII

Piston (m) RE55512, RE505102

786G

Piston (m) RE515037 Tier 2 & Tier 3

540A

Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

648GIII

Piston (m) RE527039 Tier 2 & Tier 3

660D

Piston (m) RE515037 Tier 2 & Tier 3

440A

Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 275,483

740G

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

748GII

Piston (m) RE521616 Tier 2 & Tier 3

748 G-II

High Compression Piston. To ESN 199,999. Tier 1

448D

(no special remarks)

640G

Piston (m) RE55512, RE505102

848G

Piston (m) RE515037 Tier 2 & Tier 3

640

(no special remarks)

648H

Piston (m) RE527039 Tier 2 & Tier 3

740G

Piston (m) RE515037 Tier 2 & Tier 3

440

Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

748E

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

748GIII

Piston (m) RE521616 Tier 2 & Tier 3

748 G-III

High Compression Piston. To ESN 199,999. Tier 1

540D

(no special remarks)

640GII

Piston (m) RE55512, RE505102

560D

Piston (m) RE507758 Tier 2 & Tier 3

640D

(no special remarks)

648HTJ

Piston (m) RE527039 Tier 2 & Tier 3

748G

Piston (m) RE515037 Tier 2 & Tier 3

440B

Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

748G

High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

786G

Piston (m) RE521616 Tier 2 & Tier 3

848 G

High Compression Piston. To ESN 199,999. Tier 1

548D

(no special remarks)

640GIII

Piston (m) RE55512, RE505102

660D

Piston (m) RE507758 Tier 2 & Tier 3

648D

(no special remarks)

748H

Piston (m) RE527039 Tier 2 & Tier 3

748GII

Piston (m) RE515037 Tier 2 & Tier 3

440B

Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

240

Piston (m) RE61467

848G

Piston (m) RE521616 Tier 2 & Tier 3

340D

Liter designated

648G

Piston (m) RE55512, RE505102

740G

Piston (m) RE507758 Tier 2 & Tier 3

640D

Liter designated

748HTJ

Piston (m) RE527039 Tier 2 & Tier 3

748GIII

Piston (m) RE515037 Tier 2 & Tier 3

540B

Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

8875

Piston (m) RE61270

560D

Piston (m) RE515037 Tier 2 & Tier 3

440C

Liter designated

648GII

Piston (m) RE55512, RE505102

748G

Piston (m) RE507758 Tier 2 & Tier 3

648D

Liter designated

848H

Piston (m) RE527039 Tier 2 & Tier 3

786G

Piston (m) RE515037 Tier 2 & Tier 3

340D

Large pin

8875

Piston (m) RE500211

660D

Piston (m) RE515037 Tier 2 & Tier 3

448D

Liter designated

648GIII

Piston (m) RE55512, RE505102

748GII

Piston (m) RE507758 Tier 2 & Tier 3

648E

Liter designated

848HTJ

Piston (m) RE527039 Tier 2 & Tier 3

848G

Piston (m) RE515037 Tier 2 & Tier 3

440C

Large pin

540G

Piston (m) RE55512, RE505102

740G

Piston (m) RE515037 Tier 2 & Tier 3

540D

Liter designated

460DC

Piston (m) RE527039 Tier 2 & Tier 3

748GIII

Piston (m) RE507758 Tier 2 & Tier 3

740

From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

560D

Piston (m) RE521616 Tier 2 & Tier 3

560 D

High Compression Piston. To ESN 199,999. Tier 1

340D

Liter designated

540GLL

Piston (m) RE55512, RE505102

748G

Piston (m) RE515037 Tier 2 & Tier 3

548D

Liter designated

460DG

Piston (m) RE527039 Tier 2 & Tier 3

786G

Piston (m) RE507758 Tier 2 & Tier 3

740A

Con Rod (m) R57303, R67320

660D

Piston (m) RE521616 Tier 2 & Tier 3

660 D

High Compression Piston. To ESN 199,999. Tier 1

440C

Liter designated

548G

Piston (m) RE55512, RE505102

748GII

Piston (m) RE515037 Tier 2 & Tier 3

540

O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481

640GIII

Piston (m) RE527039 Tier 2 & Tier 3

848G

Piston (m) RE507758 Tier 2 & Tier 3

约翰迪尔集材机应用的发动机零件

| 设备型号 | 备注 |

|---|---|

| 440 | O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257 |

| 740A | Con Rod (m) R71074 (P/N AR93341) |

| 740G | Piston (m) RE521616 Tier 2 & Tier 3 |

| 740 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 340D | (no special remarks) |

| 548GII | Piston (m) RE55512, RE505102 |

| 748GIII | Piston (m) RE515037 Tier 2 & Tier 3 |

| 540A | Small pin, O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, R51451, AR78310 |

| 640H | Piston (m) RE527039 Tier 2 & Tier 3 |

| 560D | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440 | Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258 |

| 740E | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 748G | Piston (m) RE521616 Tier 2 & Tier 3 |

| 748 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 440C | (no special remarks) |

| 548GIII | Piston (m) RE55512, RE505102 |

| 786G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 540A | Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310 |

| 648GIII | Piston (m) RE527039 Tier 2 & Tier 3 |

| 660D | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440A | Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 275,483 |

| 740G | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 748GII | Piston (m) RE521616 Tier 2 & Tier 3 |

| 748 G-II | High Compression Piston. To ESN 199,999. Tier 1 |

| 448D | (no special remarks) |

| 640G | Piston (m) RE55512, RE505102 |

| 848G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 640 | (no special remarks) |

| 648H | Piston (m) RE527039 Tier 2 & Tier 3 |

| 740G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440 | Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483 |

| 748E | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 748GIII | Piston (m) RE521616 Tier 2 & Tier 3 |

| 748 G-III | High Compression Piston. To ESN 199,999. Tier 1 |

| 540D | (no special remarks) |

| 640GII | Piston (m) RE55512, RE505102 |

| 560D | Piston (m) RE507758 Tier 2 & Tier 3 |

| 640D | (no special remarks) |

| 648HTJ | Piston (m) RE527039 Tier 2 & Tier 3 |

| 748G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440B | Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483 |

| 748G | High Ring Piston, Con Rod (m): R71074 (P/N AR93341) |

| 786G | Piston (m) RE521616 Tier 2 & Tier 3 |

| 848 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 548D | (no special remarks) |

| 640GIII | Piston (m) RE55512, RE505102 |

| 660D | Piston (m) RE507758 Tier 2 & Tier 3 |

| 648D | (no special remarks) |

| 748H | Piston (m) RE527039 Tier 2 & Tier 3 |

| 748GII | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440B | Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484 |

| 240 | Piston (m) RE61467 |

| 848G | Piston (m) RE521616 Tier 2 & Tier 3 |

| 340D | Liter designated |

| 648G | Piston (m) RE55512, RE505102 |

| 740G | Piston (m) RE507758 Tier 2 & Tier 3 |

| 640D | Liter designated |

| 748HTJ | Piston (m) RE527039 Tier 2 & Tier 3 |

| 748GIII | Piston (m) RE515037 Tier 2 & Tier 3 |

| 540B | Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484 |

| 8875 | Piston (m) RE61270 |

| 560D | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440C | Liter designated |

| 648GII | Piston (m) RE55512, RE505102 |

| 748G | Piston (m) RE507758 Tier 2 & Tier 3 |

| 648D | Liter designated |

| 848H | Piston (m) RE527039 Tier 2 & Tier 3 |

| 786G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 340D | Large pin |

| 8875 | Piston (m) RE500211 |

| 660D | Piston (m) RE515037 Tier 2 & Tier 3 |

| 448D | Liter designated |

| 648GIII | Piston (m) RE55512, RE505102 |

| 748GII | Piston (m) RE507758 Tier 2 & Tier 3 |

| 648E | Liter designated |

| 848HTJ | Piston (m) RE527039 Tier 2 & Tier 3 |

| 848G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 440C | Large pin |

| 540G | Piston (m) RE55512, RE505102 |

| 740G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 540D | Liter designated |

| 460DC | Piston (m) RE527039 Tier 2 & Tier 3 |

| 748GIII | Piston (m) RE507758 Tier 2 & Tier 3 |

| 740 | From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558 |

| 560D | Piston (m) RE521616 Tier 2 & Tier 3 |

| 560 D | High Compression Piston. To ESN 199,999. Tier 1 |

| 340D | Liter designated |

| 540GLL | Piston (m) RE55512, RE505102 |

| 748G | Piston (m) RE515037 Tier 2 & Tier 3 |

| 548D | Liter designated |

| 460DG | Piston (m) RE527039 Tier 2 & Tier 3 |

| 786G | Piston (m) RE507758 Tier 2 & Tier 3 |

| 740A | Con Rod (m) R57303, R67320 |

| 660D | Piston (m) RE521616 Tier 2 & Tier 3 |

| 660 D | High Compression Piston. To ESN 199,999. Tier 1 |

| 440C | Liter designated |

| 548G | Piston (m) RE55512, RE505102 |

| 748GII | Piston (m) RE515037 Tier 2 & Tier 3 |

| 540 | O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481 |

| 640GIII | Piston (m) RE527039 Tier 2 & Tier 3 |

| 848G | Piston (m) RE507758 Tier 2 & Tier 3 |

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE515037 排放 2 & 3

|

| ||||||||||||||||||||||||||||

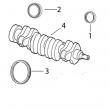

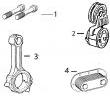

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)曲轴加工过程中必须保持适当的轴承轴颈半径,以保证正确的操作。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)检查应用程序是否正确使用。

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

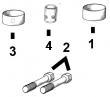

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHNDEERE起动机及起动马达常见型号:

RE523502、RE59588、RE540301、RE528929、RE515843、RE515895、RE507670、RE70957、RE70957、RE70960、RE508322、RE504009、RE70474、RE70960、RE523501、RE507943、RE528929、RE507236、RE528532、RE68470、RE51447、RE54092、RE505745、RE503226、RE509025、RE540301 SE501419、SE501844、RE520437escapes between cylinder head&gasket body, or between cylinder block&gasket body. the oil or coolant may leak to an adjacent coolant/oil passage, or externally. since oil&coolant passages are primarily on right hand (camshaft) side of the engine, fluid leaks are most likely to occur in that area. follow these diagnostic procedures when a head gasket joint failure occurs,/is suspected. 1. start&warm up engine if it can be safely operated. examine all potential leakage areas again as outlined previously. using appropriate test&measurement equipment, check the following: ? white smoke, excessive raw fuel,/moisture in exhaust system. ? rough, irregular exhaust sound,/misfiring. ? air bubbles, gas trapped in radiator/overflow tank. ? loss of coolant from overflow. ? excessive cooling system pressure. ? coolant overheating. ? low coolant flow. ? loss of cab heating (air lock) ctm86 (20mar01) 04-150-20 powertech? 8.1 l diesel engines — base engine 032001 pn=382 continued on next page observable diagnostics&tests 04 150 21 dpsg,rg40854,12 –19–25nov98–2/4 2. shut engine down. recheck crankcase, radiator, and overflow tank for any significant differences in fluid levels, viscosity,/appearance. 3. compare your observations from above steps with the diagnostic charts on the following pages. if diagnostic evaluations provide conclusive evidence of combustion gas, coolant,/oil leakage from head gasket joint, the cylinder head must be removed for inspection and repair of gasket joint components. combustion seal leakage symptoms: ? exhaust from head gasket crevice. ? air bubbles in radiator/overflow tank. ? coolant discharge from overflow tube. ? engine overheating. ? power loss. ? engine runs rough. ? white exhaust smoke. ? loss of cab heat. ? gasket section dislodged, missing (blown). ? coolant in cylinder. ? coolant in crankcase oil. ? low coolant level. possible causes: ? insufficient liner standout. ? excessive liner standout differential between cylinders. ? low head bolt clamping loads. ? rough/damaged liner flange surface. ? cracked/deformed gasket combustion flange. ? out-of-flat/damaged/rough cylinder head surface. ? missing/mislocated gasket firing ring. ? block cracked in liner support area. ? excessive fuel delivery. ? advanced injection pump timing. ? hydraulic/mechanical disturbance/combustion seal. ctm86 (20mar01) 04-150-21 powertech? 8.1 l diesel engines — base engine 032001 pn=383 continued on next page observable diagnostics&tests 04 150 22 dpsg,rg40854,12 –19–25nov98–3/4 note: cracked cylinder head/liners may also allow combustion gas leakage into coolant. if above symptoms are found, see head gasket inspection&repair sequence serial number ( —199,999) in section 02, group 020 of this manual. coolant seal leakage symptoms: ? coolant discharge from head gasket crevice. ? coolant in crankcase oil. ? low coolant level. ? high oil level. ? coolant discharge form crankcase vent. possible causes: ? excessive liner standout. ? excessive liner standout differential between cylinders. ? low head bolt clamping loads. ? out-of-flat/damaged/rough block surface. ? out-of-flat/damaged/rough cylinder head surface. ? oil/coolant overheating. ? cracks/creases in gasket body surfaces. ? damage/voids in elastomer beading. if above symptoms are found, see head gasket inspection&repair sequence serial number ( —199,999) in section 02, group 020 of this manual,/see head gasket inspection and repair sequence serial number (200,000— ) in section 02, group 021 of this manual. oil seal leakage symptoms: ? oil discharge from head gasket crevice. ? oil in coolant. ? low crankcase oil level. ? reduced oil to rocker arms (noisy). possible causes: ctm86 (20mar01) 04-150-22 powertech? 8.1 l diesel engines — base engine 032001 pn=384 continued on next page observable diagnostics&tests 04 150 23 dpsg,rg40854,12 –19–25nov98–4/4 ? excessive liner standout ? excessive liner standout differential between cylinders. ? low head bolt clamping loads ? out-of-flat/damaged/rough block surface. ? out-of-flat/damaged/rough cylinder head surface. ? oil/coolant overheating. ? cracks/creases in gasket body surfaces. ? damage/voids in elastomer beading. ? damaged/missing o-ring seal at oil port to rocker arms. if above symptoms are found, see head gasket inspection&repair sequence serial number ( —199,999) in section 02, group 020 of this manual. note: defective oil cooler may also allow oil leakage into coolant. ctm86 (20mar01) 04-150-23 powertech? 8.1 l diesel engines — base engine 032001 pn=385 observable diagnostics&tests 04 150 24 dpsg,rg40854,13 –19–25nov98–1/2 measure intake manifold pressure (turbo boost) rg9746 –un–04dec98 a—fitting b—pressure gauge note: see intake manifold pressure (turbocharger boost) specifications in section 06, group 210 of this manual. 1. remove plug from intake manifold&install the appropriate fitting (a) from jde147 manifold pressure test kit/fkm10002 universal pressure test kit. connect gauge (b)&hose assembly to fitting. be sure all connections are tight. 2. before checking boost pressure, warm up engine to allow the lubricating oil to reach operating temperature. important: engine speed&load should be stabilized before taking a gauge reading. be sure the gauge works properly&familiarize yourself with the use of the gauge. turbo boost pressure checks are only a guide to determine if there is an engine problem (valve leakage, faulty nozzle, etc.). low-pressure readings are not a conclusive reason for increasing injection pump fuel delivery. pump adjustment should be with the specifications as established by an authorized diesel repair station. on some vehicles, it may be impossible to meet the turbo boost pressure due to the inability to reach full rated speed. in these cases, see the machine’s operation&test manual for the appropriate test method&pressure. 3. observe pressure reading on gauge. boost pressure should be within ranges when engine is developing rated power at full load rated speed. see intake manifold pressure (turbocharger boost) specifications in section 06, group 210 of this manual. ctm86 (20mar01) 04-150-24 powertech? 8.1 l diesel engines — base engine 032001 pn=386 continued on next page observable diagnostics&tests 04 150 25 dpsg,rg40854,13 –19–25nov98–2/2 4. if boost pressure is too high, remove fuel injection pump&have it checked for high fuel delivery by an authorized diesel repair station. if boost pressure is too low, check for the following: ? restriction in air cleaner. ? leak in air intake between turbocharger&cylinder head. ? leak in exhaust manifold gasket. ? restricted exhaust. ? leak in fuel system piping. ? restricted fuel filter elements. ? incorrect injection pump timing. ? low fuel injection pump delivery. ? faulty fuel supply pump. ? low cylinder compression pressure. ? faulty fuel injection nozzles. ? 广州强鹿发动机皮带T23526的价格,江门johndeere活塞产品代理,枣庄强鹿进气门R93308供应商,泉州强鹿-约翰迪尔发动4039df008配件供应商,孝感约翰迪尔CD4045发电机进气门哪家好,南宁Johndeere发电机水泵总成厂家供应,贺州美国强鹿增压器RE515501厂家批发,衢州强鹿柴油机大修配件一级代理,承德强鹿柴油机后油封RE44574供货商,吉安约翰迪尔WL56装载机发动机配件一级代理,天津约翰迪尔?428000-7340配件多少钱,本溪强鹿柴油机起动机哪家买,铜川强鹿缸垫R116516公司,自贡johndeere约翰迪尔强鹿柴油机风扇厂家供应,信阳约翰迪尔强鹿连杆铜衬套R74008厂家批发,carbon build-up in turbocharger. ? turbocharger compres***/turbine wheel rubbing housing. ctm86 (20mar01) 04-150-25 powertech? 8.1 l diesel engines — base engine 032001 pn=387 observable diagnostics&tests 04 150 26 dpsg,rg40854,14 –19–25nov98–1/1 check for intake&exhaust restrictions rg9721 –un–15jan99 a—exhaust piping c—rain cap e—elbows f—connections b—muffler d—intake piping low power, low boost pressure,&excessive black exhaust smoke can be caused by an intake air or exhaust restriction. 1. inspect the exhaust piping (a), the muffler (b), and the rain cap (c) for damage/any possible restrictions. 2. inspect the intake piping (d), any elbows (e), and any connections (f). look for collapsed pipes, dented pipes&loose connections. replace components as needed. ctm86 (20mar01) 04-150-26 powertech? 8.1 l diesel engines — base engine 032001 pn=388 observable diagnostics&tests 04 150 27 dpsg,rg40854,15 –19–25nov98–1/1 test for intake air leaks t5906ap –un–23feb89 rg9747 –un–04dec98 a—intake manifold plug loose connections/cracks in the suction side of the air intake pipe can allow debris to be ingested into the engine causing rapid wear in the cylinders. additionally, on turbocharged engines, compres*** damage may occur and cause an imbalance resulting in bearing failure. air leaking from loose connections/cracks on the pressure side of the turbocharger can cause excessive smoke and low power. note: the following test procedure requires that the air intake be sealed off to pressurize the system. using a plastic bag to seal the air intake filter is used as an example. caution: do not start engine during this test procedure. plastic bag (or whatever material/object used to seal intake) can be sucked into the engine. 1. remove air cleaner cover&main filter element. 2. put a plastic bag over secondary filter element and install main element cover. 3. remove plug (a) from manifold&using a suitable adapter, connect a regulated air source. 4. pressurize air intake system to 13.8-20.7 kpa (0.13-0.21 bar) (2-3 psi). 5. spray soap&water solution over all connections from the air cleaner to the turbocharger/air inlet to check for leaks. repair all leaks. 6. remove plastic bag from filter element&reinstall element&cover. ctm86 (20mar01) 04-150-27 powertech? 8.1 l diesel engines — base engine 032001 pn=389 observable diagnostics&tests 04 150 28 dpsg,rg40854,16 –19–25nov98–1/1 check for exhaust air leaks (turbocharged engines) rg9736 –un–04dec98 a—exhaust manifold gasket b—exhaust manifold c—turbocharger gasket exhaust leaks, upstream of the turbocharger will cause the turbocharger turbine to rotate at a reduced speed resulting in low boost pressure, low power, and excessive black smoke. inspect the exhaust manifold gasket (a), the exhaust manifold (b),&the turbocharger gasket (c) for damage&any signs of leakage. replace components as needed. ctm86 KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R60914 SET SCREW 1 X X

2 R53918 PACKING 1 X X

3 T31556 NUT 1 X X

4 R68715 P, IN 1 X X

5 AR89339 SEAL 1 X X

6 AR89578 LEVER 1 X X

7 24M7054 WASHER 1 X X 6.400 X 12 X 1.600 MM

8 T24229 LOCK WASHER 2 X X

9 R68716 NUT 1 X X

10 R129240 LEVER 1 X X (A)

R504886 LEVER 1 XXXXXX- X (A)

11 19M8826 SCREW 2 X X M6 X 16

12 R53976 SCREW 1 X X (B)

13 24H1287 WASHER 1 X X (B) 9/32" X 5/8" X 0.065"

14 RE54741 LEVER 1 X X (C)

15 R68438 RETAINER 1 X X

16 R53955 O-RING 1 X X

(A) THROTTLE (TWO HOLES AT TOP) (B) NOT INCLUDED (C) SHUT-OFF

MANETTE DES GAZ NON INCLUS ROBINET D’ARRET

DROSSELKLAPPE NICHT MIT ABSCHALTUNG

ACCELERATORE NON COMPRESO RUBINETTO D’ARRESTO

ACELERADOR NO FORMA PARTE GRIFO DECIERRE

GASREGLAGE INGAAR INTE AVSTAENGINGKEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R126207 BRACKET 1 X X

2 14M7165 LOCK NUT 2 X X M6

3 RE53507 SOLENOID 1 X (A) (12 V) (SUB FOR RE54747)

RE504223 SOLENOID 1 X (A) (24 V)

4 19H1914 CAP SCREW 1 X X 1/4" X 1"

5 24H1287 WASHER 1 X X 9/32" X 5/8" X 0.065"

6 RE54741 LEVER 1 X X

7 03M7068 BOLT 1 X X M6 X 20

8 19H1900 CAP SCREW 2 X X 5/16" X 3/4"

9 24H1136 WASHER 2 X X 11/32" X 11/16" X 0.065"

10 R104592 PIPE PLUG 1 X X

11 R128694 BASE 1 X X (SUB FOR R127415) (ALSO ORDER (2)

R104592)

(A) ENERGIZE TO RUN

METTRE SOUS TENSION POUR FAIRE MARCHER

FUER BETRIEB AKTIVIEREN

ATTIVARE PER IL FUNZIONAMENTO

ACTIVAR PARA MARCHA

MAGNETISERA FOER ATT SAETTA IGAANGKEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 .. HOLDER NA X X

2 T24210 O-RING 6 X X

3 R76358 O-RING 1 X X

4 14M7272 NUT 3 X X M6

5 12M7006 LOCK WASHER 3 X X 0.236"

6 R67879 GASKET 1 X X

7 R53899 WASHER 1 X X

8 AR77114 CONTROL VALVE 1 X X

9 R53901 WASHER 1 X X

10 R63016 ADAPTER 1 X X

11 R67364 ELBOW FITTING 1 -087549 X X

RE502650 FITTING 1 087550- X X

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska