详细描述

约翰迪尔叉车应用的发动机零件

设备型号

备注

380

O'rings on liner, Con Rod (m): T20007 R81410

380

O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

480

O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

480

Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

480A

Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

480B

Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

480C

Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

482C

Liter designated, Con Rod (m): R80034, Piston (m): RE30250, RE18697

485E

Piston (m) RE59279, RE505101

486E

Piston (m) RE59279, RE505101

488E

Piston (m) RE59279, RE505101

约翰迪尔叉车应用的发动机零件

| 设备型号 | 备注 |

|---|---|

| 380 | O'rings on liner, Con Rod (m): T20007 R81410 |

| 380 | O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766 |

| 480 | O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257 |

| 480 | Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258 |

| 480A | Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483 |

| 480B | Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484 |

| 480C | Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484 |

| 482C | Liter designated, Con Rod (m): R80034, Piston (m): RE30250, RE18697 |

| 485E | Piston (m) RE59279, RE505101 |

| 486E | Piston (m) RE59279, RE505101 |

| 488E | Piston (m) RE59279, RE505101 |

约翰迪尔 6081 高压缩活塞

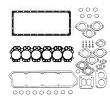

约翰迪尔(John Deere) 强鹿6081柴油发动机高压缩活塞大修包TOK504201

|

型号 |

数量 |

描述 |

|

TAR49025 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE |

|

TR116081 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准 |

|

TR66452 |

12 |

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉 |

|

TR74008 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套 |

|

TR87561 |

4 |

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套 |

|

TRE529319 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准) |

|

TRE529320 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准) |

|

TRE506220 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机大修包 |

|

TRE520036 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR |

|

TRE64509 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 |

约翰迪尔(John Deere) 强鹿6081柴油发动机大修包TOK504201A

|

型号 |

数量 |

描述 |

|

TAR49025 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE |

|

TR116081 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准 |

|

TR501035 |

12 |

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉 |

|

TR74008 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套 |

|

TR87561 |

4 |

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套 |

|

TRE529319 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准) |

|

TRE529320 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准) |

|

TRE506220 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机大修包 |

|

TRE520036 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR |

|

TRE64509 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 |

约翰迪尔(John Deere) 强鹿6081柴油发动机内部修理套件TIK504201

|

型号 |

数量 |

描述 |

|

TR116081 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准 |

|

TR66452 |

12 |

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉 |

|

TR71918 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机GASKET, OIL PAN |

|

TRE529319 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准) |

|

TRE529320 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准) |

|

TRE506222 |

1 |

约翰迪尔(John Deere) 强鹿6081发动机GASKET, CYL HEAD SET |

|

TRE64509 |

6 |

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 |

|

| |||||||||||||||||||||||||||

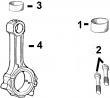

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

(3)用铝油盘使用TR49377(RE504822)。

(4)使用TR66452杆式螺栓和机器分体式连杆,并使用带断裂分体式连杆的TR501035杆式螺栓。

(5)发动机ESN 199,999及以下。 仅适用于Exaust Valves。

(6)发动机ESN 200,000及以上。 仅适用于Exaust Valves。

(7)发动机ESN 199,999及以下。

(8)发动机ESN 200,000及以上。

(9)检查应用程序是否正确使用。

(10)机器分体连杆。 使用棒螺栓TR66452。

(11)破裂的分裂连杆。 使用棒螺栓TR501035。

(12)高流量。

(13)与断裂分体连杆一起使用。

, 强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

4039DF004、6068HF252、4039DF005、4039DF008、6076TF010、6059TF001、4045HF275、RG6125、6135H458、4045DFM70, 4045TFM75, 6068TFM75, 6068TFM76、6068HF275、6125HF070\6125AF001,4039DFM、6125HF070、6135HF475-2、6135HF475-3 RW9400T、3029DF120、RG6081、TO4039、TO6068、6135SM75、6135HF485、4045HF275、RG6125、6135H458、4045DFM70, 4045TFM75, 6068TFM75, 6068TFM76、6068HF275、4039DFMvoltage low rg10394 –19–19dec00 note: wiring diagram shows oem engine applications. for wiring information non-oem engines, refer to machine manual. wif (water in fuel) sen*** ? the wif sen*** uses the resistance of water and fuel to detect the presence of water in the fuel system. this uses the principle that water is a better conductor of electricity than fuel is. because of this, the water in fuel sen*** will read a lower voltage when water is present than when it is not present. for further wif sen*** information, see water in fuel sen*** in section 03, group 140. dtc spn 97 fmi 4 will set if: ? the wif input voltage is below a 0.5 volts. this voltage corresponds to an amount of water in fuel that is not possible. if dtc spn 97 fmi 4 sets, the following will occur: ? ecu’s wif engine protection feature disabled. ctm188 (20mar01) 04-160-100 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=288 trouble code diagnostics&tests ouo1004,0000c93 –19–08jan01–1/1 level 6 ecu - dtc spn 97 fmi 4 water in fuel signal voltage low - continued – – –1/1 level 6 ecu - dtc spn 97 fmi 4 water in fuel signal voltage low diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the wif sen*** connector/looking for dirty, damaged,/poorly positioned terminals. 04 160 101 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 97 fmi 4 water in fuel signal voltage low supporting information 1. ignition on, engine off 2. using the dst, make note of all dtcs, then clear all dtcs 3. ignition on, engine off 4. using the dst, monitor dtcs on the active code display parameter spn 97 fmi 4 reoccurs: go to 2 spn 97 fmi 4 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 water in fuel (wif) sen*** test note: for wiring&theory of operation information, see dtc spn 97 fmi 4 water in fuel signal voltage low supporting information 1. ignition off 2. disconnect wif sen*** connector 3. make note of all dtcs, then clear all dtcs 4. ignition on 5. using the dst, monitor dtcs on the active code display parameter spn 97 fmi 4 reoccurs: short to ground in wif sen*** input circuit or faulty ecu spn 97 fmi 3 occurs: faulty wif sen*** ctm188 (20mar01) 04-160-101 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=289 trouble code diagnostics&tests 04 160 102 dpsg,rg40854,308 –19–26aug99–1/1 level 6 ecu - dtc spn 97 fmi 16 water in fuel detected rg10394 –19–19dec00 note: wiring diagram shows oem engine applications. for wiring information non-oem engines, refer to machine manual. wif (water in fuel) sen*** ? the wif sen*** uses the resistance of water and fuel to detect the presence of water in the fuel system. this uses the principle that water is a better conductor of electricity than fuel is. because of this, water in fuel sen*** will read a lower voltage when water is present than when it is not present. for further wif sen*** information, see water in fuel sen*** in section 03, group 140. dtc spn 97 fmi 16 will set if: ? the wif is above a predetermined quantity at any given time. if dtc spn 97 fmi 16 sets, the following will occur: ? ecu’s that have engine protection: – will derate the engine (dtc spn 1569 fmi 31 will also be present) 2% per minute to a maximum derate of 20%. when wif drops back below the maximum value set point, power will be increased 2% per minute until either full power is reached or if the maximum value set point is surpassed again. note: the derate program shown applies to oem engine applications that contain engine protection. other applications may have a similar derate program. refer to specific machine manual for application derate programs. ctm188 (20mar01) 04-160-102 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=290 trouble code diagnostics&tests ouo1004,0000c94 –19–08jan01–1/1 level 6 ecu - dtc spn 97 fmi 16 water in fuel detected - continued – – –1/1 level 6 ecu - dtc spn 97 fmi 16 water in fuel detected diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the wif sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 103 – – –1/1 1 moisture buildup test 1. key off 2. drain sediment bowl on the bottom of the primary fuel filter until all the water is out 3. operate engine in normal use 4. using the dst, monitor dtcs on the active code display parameter spn 97 fmi 16 reoccurs: go to 2 spn 97 fmi 16 doesn’t reoccur: problem is was most likely caused by moisture build up over time monitor the sediment bowl for moisture periodically, drain as needed – – –1/1 2 water in fuel (wif) circuit&sen*** test note: for wiring&theory of operation information, see dtc spn 97 fmi 16 water in fuel detected supporting information check the following items that can cause water in the fuel: ? poor fuel quality/water in fuel storage tank ? loose fuel tank cap ? missing/damaged fuel tank cap seal ? excessive condensation build up in fuel tank ? loose/damaged fuel filter/sediment bowl cause of water in fuel located: repair problem, drain sediment bowl,&retest no cause of water in fuel located: verify that wif sen*** input&ground circuits are ok. if wif sen*** circuits are ok, replace wif sen*** and retest ctm188 (20mar01) 04-160-103 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=291 trouble code diagnostics&tests 04 160 104 dpsg,rg40854,309 –19–26aug99–1/1 level 6 ecu - dtc spn 97 fmi 31 water in fuel detected rg10394 –19–19dec00 note: wiring diagram shows oem engine applications. for wiring information non-oem engines, refer to machine manual. wif (water in fuel) sen*** ? the wif sen*** uses the resistance of water and fuel to detect the presence of water in the fuel system. this uses the principle that water is a better conductor of electricity than fuel is. because of this, the water in fuel sen*** will read a lower voltage when water is present than when it is not present. for further wif sen*** information, see water in fuel sen*** in section 03, group 140. dtc spn 97 fmi 31 will set if: ? the wif is above a predetermined quantity at a given time. if dtc spn 97 fmi 31 sets, the following will occur: wif detected: ? ecu’s that have engine protection: – will derate the engine (dtc spn 1569 fmi 31 will also be present) 2% per minute to a maximum derate of 20%. when wif drops back below the maximum value set point, power will be increased 2% per minute until either full power is reached or if the maximum value set point is surpassed again. if wif detected in spite of the derate above: ? ecu’s that have engine protection with shutdown: – will severely derate the engine (dtc spn 1569 fmi 31 will also be present). if wif does not set within the shutdown value within 30 seconds, the ecu will shut down the engine. note: for oem applications, the engine derates 20% per minute until the engine has been derated by 40%. ? ecus that have engine protection without shutdown: – will severely derate the engine (dtc spn 1569 fmi 31 will also be present), but will not shut the engine down. note: for oem applications, the engine derates 20% per minute until the engine has been derated by 40%. ctm188 (20mar01) 04-160-104 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=292 trouble code diagnostics&tests ouo1004,0000c95 –19–08jan01–1/1 level 6 ecu - dtc spn 97 fmi 31 water in fuel detected - continued 广安强鹿6081发动机活塞销代理商,聊城强鹿柴油机活塞缸套组件RE536083一级代理,益阳强鹿柴油机AR67942前油封批发商,萍乡约翰迪尔柴油机凸轮轴下衬套诚信推荐,葫芦岛johndeere约翰迪尔强鹿柴油发动机曲轴瓦RE65165信息,长沙约翰迪尔甘蔗机发动机配件厂家批发,湘西约翰迪尔4045TF机油泵厂家供货,吉安约翰迪尔6081柴油机排气门导管信息,无堂划分域JOHNDEERE强鹿柴油机增压器RE503722找哪家,玉林强鹿柴油机3029电子燃油泵哪里买,银川强鹿发动机大修包厂家批发,玉溪约翰迪尔喷油器RE543935批发,黄山约翰迪尔强鹿4045柴油机止推轴承RE65912哪里买,延边JohnDeere气门弹簧RE516486市场报价,澳门半岛JohnDeere加大主轴瓦RE534181找哪家,昌吉美国JohnDeere启动马达RE523502信息,南昌强鹿柴油机曲轴齿轮R114282价格行情,洛阳约翰迪尔强鹿张紧轮RE518097厂家供货,舟山强鹿6090柴油发动机气门弹簧厂家价格,伊春强鹿滤芯滤清器RE59574厂家供货,澳门半岛JohnDeere加大主轴瓦RE534181价格行情,呼和浩特johndeere约翰迪尔强鹿柴油发动机曲轴后油封RE53687信息,滨州强鹿发动机大修包RE526975批发商,梧州强鹿6090柴油发动机进气门代理,宣城约翰迪尔6090柴油机气门导管价格行情,和田强鹿柴油发动机缸套水封圈AR98850的价格,白城强鹿柴油机大修包批发商,眉山美国约翰迪尔(强鹿)发电机纯正配件市场报价,阿里JohnDeere衬垫套RE527552价格,梅州强鹿柴油机进排气门价格行情,山南强鹿柴油机大修包OK6090一级代理,孝感约翰迪尔CD4045发电机进气门代理,鄂尔多斯强鹿机滤RE58935代理商,台南约翰迪尔强鹿涨紧轮re2490多少钱,林芝强鹿进气门R97490厂家供应,铁岭约翰迪尔强鹿4045柴油机曲轴齿轮供应商,绥化johndeere约翰迪尔强鹿柴油发动机缸垫RE522278信息,长治约翰迪尔R122191批发,海东约翰迪尔发动机大修包批发,喀什强鹿衬垫套RE527552厂家批发,黔南约翰迪尔柴油发电机组缸盖代理,长春强鹿传感器RE5026的价格,衢州强鹿柴油发动机柱塞厂家供应,鹤岗JOHNDEERE强鹿6068TF275配件批发商,三明JohnDeere曲轴RE535300代理,信阳约翰迪尔曲轴齿轮R28811公司,漳州强鹿柴油机止推片公司,温州约翰迪尔4045柴油机连杆RE500608哪家买,吕梁约翰迪尔挖掘机进排气门批发,江门约翰迪尔发动机维修保养配件信息,1/1 level 6 ecu - dtc spn 97 fmi 31 water in fuel detected diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the wif sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 105 – – –1/1 1 moisture buildup test 1. key off 2. drain sediment bowl on the bottom of the primary fuel filter until all the water is out 3. operate engine in normal use 4. using the dst, monitor dtcs on the active code display parameter spn 97 fmi 31 reoccurs: go to 2 spn 97 fmi 31 doesn’t reoccur: problem is was most likely caused by moisture build up over time monitor the sediment bowl for moisture periodically, drain as needed – – –1/1 2 water in fuel (wif) circuit&sen*** test note: for wiring&theory of operation information, see dtc spn 97 fmi 31 water in fuel detected supporting information check the following items that can cause water in the fuel: ? poor fuel quality/water in fuel storage tank ? loose fuel tank cap ? missing/damaged fuel tank cap seal ? excessive condensation build up in fuel tank ? loose/damaged fuel filter/sediment bowl cause of water in fuel located: repair problem, drain sediment bowl,&retest no cause of water in fuel located: verify that wif sen*** input&ground circuits are ok. if wif sen*** circuits are ok, replace wif sen*** and retest ctm188 (20mar01) 04-160-105 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=293 trouble code diagnostics&tests 04 160 106 dpsg,rg40854,310 –19–26aug99–1/1 level 6 ecu - dtc spn 100 fmi 1 engine oil pressure extremely low rg10395 –19–19dec00 important: do not force probes into connector terminals/damage will result. use, jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. oil pressure sen*** ? the oil pressure sen*** is a pressure transducer connected to the main oil galley/oil cooler. the oil pressure input voltage varies as oil pressure varies. as engine oil pressure increases, the oil pressure sen*** input voltage increases. the ecu monitors oil pressure in order to protect the engine in case of a low oil pressure condition. for further oil pressure sen*** information, see measuring pressure in section 03, group 140. dtc spn 100 fmi 1 will set if: ? the ecu senses an oil pressure below the shutdown value set point in the ecu. the shutdown value set point is dependent on engine speed. if dtc spn 100 fmi 1 sets, the following will occur: ? ecus that have engine protection with shutdown: – will severely derate the engine (dtc spn 1569 fmi 31 will also be present). if oil pressure does not increase above the shutdown value set point within 30 seconds, the ecu will shut the engine down. note: for oem applications, the engine derates 20% per minute until the engine has been derated by 40%. ? ecus that have engine protection without shutdown: – will severely derate the engine (dtc spn 1569 fmi 31 will also be present), but will not shut the engine down. note: for oem applications, the engine derates 20% per minute until the engine has been derated by 40%. ? ecus that have no engine protection: – there will be no derate&the ecu will not shut the engine down. ctm188 (20mar01) 04-160-106 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=294 trouble code diagnostics&tests ouo1004,0000c96 –19–08jan01–1/1 level 6 ecu - dtc spn 100 fmi 1 engine oil pressure extremely low - continued – – –1/1 level 6 ecu - dtc spn 100 fmi 1 engine oil pressure extremely low diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the oil pressure sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 107 – – –1/1 1 oil pressure test note: for wiring&theory of operation information, see dtc spn 100 fmi 1 engine oil pressure extremely low supporting information. under the conditions where dtc spn 100 fmi 1 occurs, measure engine oil pressure. see check engine oil pressure in ctm100, section 04, group 150. oil pressure below specification: low oil pressure problem. see l3 - engine oil pressure low in ctm100, section 04, group 150. oil pressure within specification: verify that oil pressure sen*** 5 v supply, input, and ground circuits are ok. if oil pressure sen*** circuits are ok, replace oil pressure sen*** and retest ctm188 (20mar01) 04-160-107 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=295 trouble code diagnostics&tests 04 160 108 dpsg,rg40854,311 –19–26aug99–1/1 level 6 ecu - dtc spn 100 fmi 3 engine oil pressure input voltage high rg10395 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. oil pressure sen*** ? the oil pressure sen*** is a pressure transducer connected to the main oil galley/oil cooler. the oil pressure input voltage varies as oil pressure varies. as engine oil pressure increases, the oil pressure sen*** input voltage increases. the ecu monitors oil pressure in order to protect the engine in case of a low oil pressure condition. for further oil pressure sen*** information, see measuring pressure in section 03, group 140. dtc spn 100 fmi 3 will set if: ? the oil pressure input voltage exceeds a 4.5 volts. this voltage corresponds to an oil pressure that is higher that what is physically possible for oil pressure. if dtc spn 100 fmi 3 sets, the following will occur: ? ecu’s low oil pressure engine protection feature disabled. ctm188 (20mar01) 04-160-108 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=296 trouble code diagnostics&tests ouo1004,0000c97 –19–08jan01–1/1 level 6 ecu - dtc spn 100 fmi 3 engine oil pressure input voltage high - continued – – –1/1 level 6 ecu - dtc spn 100 fmi 3 engine oil pressure input voltage high diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the oil pressure sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 109 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 100 fmi 3 engine oil pressure input voltage high supporting information. 1. warm engine 2. ignition on, engine running 3. using the dst, read the oil pressure voltage parameter 4.5 v/greater: go to 2 below 4.5 v: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 oil pressure input shorted test n, ote: for wiring&theory of operation information, see dtc spn 100 fmi 3 engine oil pressure input voltage high supporting information. 1. ignition off 2. disconnect oil pressure sen*** connector 3. ignition on, engine off 4. using the dst, read the oil pressure voltage parameter below 0.25 v: go to 3 0.25 v/greater: short to voltage in oil pressure sen*** input circuit or faulty ecu – – –1/1 3 oil pressure ground circuit open test note: for wiring&theory of operation information, see dtc spn 100 fmi 3 engine oil pressure input voltage high supporting information. probe oil pressure sen*** ground (terminal a) in sen*** harness connector with a test light connected to battery voltage light on: faulty oil pressure sen*** or faulty ecu connection or faulty ecu light off: open in oil pressure sen*** ground circuit or faulty ecu connection or faulty ecu ctm188 (20mar01) 04-160-109 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=297 trouble code diagnostics&tests 04 160 110 dpsg,rg40854,312 –19–26aug99–1/1 level 6 ecu - dtc spn 100 fmi 4 engine oil pressure input voltage low rg10395 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. oil pressure sen*** ? the oil pressure sen*** is a pressure transducer connected to the main oil galley/oil cooler. the oil pressure input voltage varies as oil pressure varies. as engine oil pressure increases, the oil pressure sen*** input voltage increases. the ecu monitors oil pressure in order to protect the engine in case of a low oil pressure condition. for further oil pressure sen*** information, see measuring pressure in section 03, group 140. dtc spn 100 fmi 4 will set if: ? the oil pressure input voltage drops below 0.25 volts. this voltage corresponds to an oil pressure that is lower that what is physically possible for oil pressure. if dtc spn 100 fmi 4 sets, the following will occur: ? ecu’s low oil pressure engine protection feature disabled. ctm188 (20mar01) 04-160-110 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=298 trouble code diagnostics&tests ouo1004,0000c98 –19–08jan01–1/1 level 6 ecu - dtc spn 100 fmi 4 engine oil pressure input voltage low - continued – – –1/1 level 6 ecu - dtc spn 100 fmi 4 engine oil pressure input voltage low diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of 60-way ecu connector&the oil pressure sen*** connector, looking for dirty, damaged,/poorly positioned terminals. 04 160 111 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 100 fmi 4 engine oil pressure input voltage low supporting information. 1. warm engine 2. ignition on, engine running 3. using the dst, read the oil pressure voltage parameter 0.25 v/less: go to 2 above 0.25 v: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 oil pressure sen*** and connector test note: for wiring&theory of operation information, see dtc spn 100 fmi 4 engine oil pressure input voltage low supporting information. 1. ignition off 2. disconnect oil pressure sen*** connector 3. install a jumper wire between oil pressure sen*** 5 v supply&the oil pressure input terminal in sen*** harness connector 4. ignition on, engine off 5. using the dst, read the oil pressure voltage parameter below 4.5 v: go to 3 4.5 v/greater: faulty oil pressure sen*** connection or faulty oil pressure sen*** ctm188 (20mar01) 04-160-111 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=299 trouble code diagnostics&tests 04 160 112 – – –1/1 3 oil pressure 5 v supply test note: for wiring&theory of operation information, see dtc spn 100 fmi 4 engine oil pressure input voltage low supporting information. 1. ignition off 2. remove jumper wire 3. ignition on, engine off 4. using a multimeter, measure voltage between the 5 v supply (terminal b) of the oil pressure sen*** harness connector&a good chassis ground 4.0 - 6.0 v: open in oil pressure sen*** input circuit or short to ground in oil pressure sen*** input circuit or faulty ecu connection or faulty ecu below 4.0 v: open in oil pressure sen*** 5 v supply circuit or short to ground in oil pressure sen*** 5 v supply circuit or faulty ecu connection or faulty ecu ctm188 (20mar01) 04-160-112 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=300 trouble code diagnostics&tests 04 160 113 ctm188 (20mar01) 04-160-113 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=301 trouble code diagnostics&tests 04 160 114 dpsg,rg40854,313 –19–26aug99–1/1 level 6 ecu - dtc spn 100 fmi 18 engine oil pressure moderately low rg10395 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. oil pressure sen*** ? the oil pressure sen*** is a pressure transducer connected to the main oil galley/oil cooler. the oil pressure input voltage varies as oil pressure varies. as engine oil pressure increases, the oil pressure sen*** input voltage increases. the ecu monitors oil pressure in order to protect the engine in case of a low oil pressure condition. for further oil pressure sen*** information, see measuring pressure in section 03, group 140. dtc spn 100 fmi 18 will set if: ? the ecu senses an oil pressure below the warning value set point in the ecu. the warning value set point is dependent on engine speed. if dtc spn 100 fmi 18 sets, the following will occur: ? ecus that have engine protection: – will derate 2% per minute to a maximum derate of 20%. when oil pressure increases above the minimum value set point, power will be increased 2% per minute until either full power is reached or if the maximum value set point is surpassed again. – if in spite of the derate, oil pressure continues to drop, ecus that have engine protection with shutdown, will shut down the engine when oil pressure drops below the shutdown value set point in the ecu. the shutdown value setpoint is dependent of engine speed. note: the derate program shown applies to oem engine applications that contain engine protection. other applications may have a similar derate program. refer to specific machine manual for application derate programs. ctm188 (20mar01) 04-160-114 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=302 trouble code diagnostics&tests ouo1004,0000c99 –19–08jan01–1/1 level 6 ecu - dtc spn 100 fmi 18 engine oil pressure moderately low - continued – – –1/1 level 6 ecu - dtc spn 100 fmi 18 engine oil pressure moderately low diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the oil pressure sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 115 – – –1/1 1 oil pressure test note: for wiring&theory of operation information, see dtc spn 100 fmi 18 engine oil pressure moderately low supporting information. under the conditions where dtc spn 100 fmi 1 occurs, measure engine oil pressure. see check engine oil pressure in ctm100, section 04, group 150. oil pressure below specification: low oil pressure problem. see l3 - engine oil pressure low in ctm100, section 04, group 150. oil pressure within specification: verify that oil pressure sen*** 5 v supply, input, and ground circuits are ok. if oil pressure sen*** circuits are ok, replace oil pressure sen*** and retest ctm188 (20mar01) 04-160-115 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=303 trouble code diagnostics&tests 04 160 116 rg40854,0000002 –19–19dec00–1/1 level 6 ecu - dtc spn 102 fmi 3 manifold air pressure input voltage high rg11623 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. map (manifold air pressure) sen*** the map sen*** is a pressure transducer connected to intake manifold air pressure. it is used to measure the air pressure in the intake manifold. the map input voltage varies as intake manifold pressure varies. as pressure increases, input voltage to the ecu increases. the ecu uses the map sen*** input in conjunction with the mat sen*** input to determine engine air flow. dtc spn 102 fmi 3 will set if: ? the map input voltage exceeds 4.75 volts. this voltage corresponds to a pressure that is higher than what is physically possible for manifold air. if dtc spn 102 fmi 3 sets, the following will occur: ? the ecu will not apply engine protection. ctm188 (20mar01) 04-160-116 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=304 trouble code diagnostics&tests ouo1004,0000c9a –19–08jan01–1/1 level 6 ecu - dtc spn 102 fmi 3 manifold air pressure input voltage high - continued – – –1/1 level 6 ecu - dtc spn 102 fmi 3 manifold air pressure input voltage high diagnostic procedure 04 160 117 – – –1/1 1 dtc spn 102 fmi 3 - preliminary check if engine idle is rough/unstable due to a suspected engine mechanical problem, correct the condition before continuing to use this diagnostic procedure engine mechanical condition ok: go to 2 – – –1/1 2 intermittent fault test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 3 manifold air pressure input voltage high supporting information 1. ignition on, engine idling 2. using the dst, monitor dtcs on the active code display parameter 3. make notes of any dtcs, then clear all dtcs 4. ignition on, engine idling 5. using the dst, monitor dtcs on the active code display parameter spn 102 fmi 3 reoccurs: go to 3 spn 102 fmi 3 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 3 map input shorted test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 3 manifold air pressure input voltage high supporting information 1. ignition off 2. disconnect map sen*** connector 3. ignition on, engine running 4. using the dst, monitor dtcs on the active code display parameter spn 102 fmi 4 occurs: go to 4 spn 102 fmi 3 reoccurs: short to voltage in map input circuit or faulty ecu ctm188 (20mar01) 04-160-117 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=305 trouble code diagnostics&tests – – –1/1 4 map ground circuit open test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 3 manifold air pressure input voltage high supporting information 1. ignition off 2. probe map ground (terminal a) in harness sen*** connector with a test light connected to battery voltage light on: plugged/leaking map sen*** air supply or faulty ecu connection or faulty map sen*** light off: open in map ground circuit 04 160 118 ctm188 (20mar01) 04-160-118 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=306 trouble code diagnostics&tests 04 160 119 ctm188 (20mar01) 04-160-119 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=307 trouble code diagnostics&tests 04 160 120 rg40854,0000003 –19–19dec00–1/1 level 6 ecu - dtc spn 102 fmi 4 manifold air pressure input voltage low rg11623 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. map (manifold air pressure) sen*** the map sen*** is a pressure transducer connected to intake manifold air pressure. it is used to measure the air pressure in the intake manifold. the map input voltage varies as intake manifold pressure varies. as pressure increases, input voltage to the ecu increases. the ecu uses the map sen*** input in conjunction with the mat sen*** input to determine engine air flow. dtc spn 102 fmi 4 will set if: ? the map input voltage goes below 0.25 volts. this voltage corresponds to a pressure that is lower than what is physically possible for manifold air. if dtc spn 102 fmi 4 sets, the following will occur: ? the ecu will not apply engine protection. ctm188 (20mar01) 04-160-120 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=308 trouble code diagnostics&tests ouo1004,0000c9b –19–08jan01–1/1 level 6 ecu - dtc spn 102 fmi 4 manifold air pressure input voltage low - continued – – –1/1 level 6 ecu - dtc spn 102 fmi 4 manifold air pressure input voltage low diagnostic procedure 04 160 121 – – –1/1 1 intermittent fault test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 4 manifold air pressure input voltage low supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make notes of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 102 fmi 4 reoccurs: go to 2 spn 102 fmi 4 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 map wiring test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 4 manifold air pressure input voltage low supporting information. 1. ignition off 2. disconnect map sen*** connector 3. install a jumper wire between map 5 v supply (terminal c)&map input (terminal b) in harness sen*** connector 4. ignition on, engine off 5. using the dst, monitor dtcs on the active code display parameter spn 102 fmi 3 occurs: go to 3 spn 102 fmi 4 reoccurs: faulty map sen*** connection or faulty map sen*** ctm188 (20mar01) 04-160-121 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=309 trouble code diagnostics&tests 04 160 122 – – –1/1 3 map 5 v supply test note: for wiring, theory of operation,&sen*** location information, see dtc spn 102 fmi 4 manifold air pressure input voltage low supporting information. 1. ignition off 2. remove jumper wire 3. ignition on, engine off 4. using a multimeter, measure voltage between map ground (terminal a)&map 5 v supply (terminal c) in harness sen*** connector 4.0 - 6.0 v: open in map input circuit or short to ground in map input circuit or faulty ecu connection or faulty ecu below 4.0 v: open in map 5 v supply circuit or short to ground in map 5 v supply circuit or faulty ecu connection or faulty ecu ctm188 (20mar01) 04-160-122 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=310 trouble code diagnostics&tests 04 160 123 ctm188 (20mar01) 04-160-123 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=311 trouble code diagnostics&tests 04 160 124 dpsg,rg40854,172 –19–28jun99–1/1 level 6 ecu - dtc spn 105 fmi 3 manifold air temperature input voltage high rg10396 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. mat (manifold air temperature) sen*** ? the mat sen*** is a thermistor (temperature sensitive resistor) mounted in the intake manifold. the mat sen*** is used to measure the temperature of the intake air. the mat sen***’s variable resistance causes the input voltage to the ecu to vary. higher intake air temperatures result in lower mat input voltages to the ecu; lower temperatures result in higher voltages. the ecu uses the mat sen*** input in conjunction with the map sen*** input to determine engine air flow. for further mat sen*** information, see measuring temperature in section 03, group 140. dtc spn 105 fmi 3 will set if: ? the mat input voltage exceeds 4.8 volts. this voltage corresponds to a temperature that is lower than what is physically possible for manifold air. if dtc spn 105 fmi 3 sets, the following will occur: ? the ecu will use a default “limp-home” mat value of 50°c (122°f). ? ecu’s high manifold air temperature engine protection feature disabled. ctm188 (20mar01) 04-160-124 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=312 trouble code diagnostics&tests ouo1004,0000c9c –19–08jan01–1/1 level 6 ecu - dtc spn 105 fmi 3 manifold air temperature input voltage high - continued – – –1/1 level 6 ecu - dtc spn 105 fmi 3 manifold air temperature input voltage high diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the mat sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 125 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 105 fmi 3 manifold air temperature input voltage high supporting information. 1. warm engine 2. ignition on, engine off/running 3. using the dst, read the manifold air temperature voltage parameter 4.8 v/greater: go to 2 below 4.8 v: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 manifold air temperature (mat) sen*** and connector test note: for wiring&theory of operation information, see dtc spn 105 fmi 3 manifold air temperature input voltage high supporting information. 1. ignition off 2. disconnect mat sen*** connector 3. install a jumper wire between both terminals in the mat sen*** harness connector 4. ignition on, engine off 5. using the dst, read the manifold air temperature voltage parameter greater than 0.1 v: go to 3 0.1 v/less: faulty mat sen*** connector or faulty mat sen*** ctm188 (20mar01) 04-160-125 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=313 trouble code diagnostics&tests 04 160 126 – – –1/1 3 manifold air temperature (mat) sen*** open ground circuit test note: for wiring&theory of operation information, see dtc spn 105 fmi 3 manifold air temperature input voltage high supporting information. 1. remove jumper wire between both terminals 2. install jumper wire between mat sen*** harness connector input terminal&a good chassis ground 3. using the dst, read the manifold air temperature voltage parameter greater than 0.1 v: open in mat sen*** input circuit or faulty ecu connection or faulty ecu 0.1 v/less: open in mat sen*** ground circuit or faulty ecu connection or faulty ecu ctm188 (20mar01) 04-160-126 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=314 trouble code 怒江约翰迪尔柴油发动机输油泵RE68345哪家好,武威强鹿发动机RE55343凸轮轴衬套找哪家,鸡西强鹿柴油发电机组四配套诚信推荐,河池强鹿柴油机加热器TRE502079批发商,玉溪约翰迪尔滑移装载机发动机配件批发价,益阳强鹿柴油机AR67942前油封厂家供货,洛阳约翰迪尔柴油滤清器RE60021代理商,铜陵强鹿3029柴油机R98062进气门批发商,晋城约翰迪尔6081柴油机加大连杆瓦厂家批发,巴彦淖尔强鹿约翰迪尔3029气缸盖螺丝厂家供应,南京强鹿柴油发动机空气滤F040A6供应商,遂宁约翰迪尔强鹿活塞环厂家价格,diagnostics&tests 04 160 127 ctm188 (20mar01) 04-160-127 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=315 trouble code diagnostics&tests 04 160 128 dpsg,rg40854,173 –19–28jun99–1/1 level 6 ecu - dtc spn 105 fmi 4 manifold air temperature input voltage low rg10396 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. mat (manifold air temperature) sen*** ? the mat sen*** is a thermistor (temperature sensitive resistor) mounted in the intake manifold. the mat sen*** is used to measure the temperature of the intake air. the mat sen***’s variable resistance causes the input voltage to the ecu to vary. higher intake air temperatures result in lower mat input voltages to the ecu; lower temperatures result in higher voltages. the ecu uses the mat sen*** input in conjunction with the map sen*** input to determine engine air flow. for further mat sen*** information, see measuring temperature in section 03, group 140. dtc spn 105 fmi 4 will set if: ? the mat input voltage drops below 0.1 volts. this voltage corresponds to a temperature that is higher than what is physically possible for manifold air. if dtc spn 105 fmi 4 sets, the following will occur: ? the ecu will use a mat default “limp-home” mat value of 50°c (122°f). ? ecu’s high manifold air temperature engine protection feature disabled. ctm188 (20mar01) 04-160-128 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=316 trouble code diagnostics&tests ouo1004,0000c9d –19–08jan01–1/1 level 6 ecu - dtc spn 105 fmi 4 manifold air temperature input voltage low - continued – – –1/1 level 6 ecu - dtc spn 105 fmi 4 manifold air temperature input voltage low diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the mat sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 129 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 105 fmi 4 manifold air temperature input voltage low supporting information. 1. warm engine 2. ignition on, engine off/running 3. using the dst, read the manifold air temperature voltage parameter 0.1 v/less: go to 2 above 0.1 v: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 manifold air temperature (mat) sen*** test note: for wiring&theory of operation information, see dtc spn 105 fmi 4 manifold air temperature input voltage low supporting information. 1. ignition off 2. disconnect mat sen*** connector 3. ignition on 4. using the dst, read the manifold air temperature voltage parameter below 4.8 v: short to ground in mat sen*** input circuit or faulty ecu 4.8 v/greater: faulty mat sen*** ctm188 (20mar01) 04-160-129 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=317 trouble code diagnostics&tests 04 160 130 KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

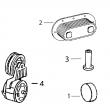

1 .. HOLDER NA X

2 T24210 O-RING 6 X

3 R76358 O-RING 1 X

4 14M7272 NUT 3 X M6

5 12M7006 LOCK WASHER 3 X 0.236"

6 R67879 GASKET 1 X

7 R53899 WASHER 1 X

8 AR77114 CONTROL VALVE 1 X

9 R53901 WASHER 1 X

10 R63016 ADAPTER 1 X

11 R67364 ELBOW FITTING 1 -087549 X

RE502650 FITTING 1 087550- X

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

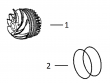

1 RE65265 HAND PRIMER 1 X (SUB FOR RE48048)

2 R54025 WASHER 1 X

3 R26448 O-RING 2 X

4 RE34128 ELBOW FITTING 1 X (A)

RE10258 ELBOW FITTING 1 X (B)

5 R67879 GASKET 1 X

6 RE46252 FUEL PUMP 1 X (ROBERT BOSCH)

7 R93008 WASHER NA X

8 R83489 FITTING NA X

(A) INLET (B) OUTLET

ENTREE SORTIE

EINLASS AUSCLASSE

ENTRATA USCITA

ENTRADA SALIDA

INLOPP UTLOPP

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE57151 FUEL LINE 1 X NO. 6

2 RE57150 FUEL LINE 1 X NO. 5

3 RE57149 FUEL LINE 1 X NO. 4

4 R71398 SCREW 5 X

R58186 CLAMP 10 X

R59305 STRAP 5 X

R61144 STRAP 5 X

R74030 CLAMP 1 X

5 RE57148 FUEL LINE 1 X NO. 3

6 RE57147 FUEL LINE 1 -081549 X NO. 2

RE502933 FUEL LINE 1 081550- X NO. 2

7 RE57146 FUEL LINE 1 -081549 X NO. 1

RE502932 FUEL LINE 1 081550- X NO. 1

8 21H1463 CAP SCREW 2 X 0.190" X 7/8"

R59298 STRAP 1 X

R61145 STRAP 1 X

R120184 STRAP 1 X

R59297 HALF CLAMP 2 X

9 R59298 STRAP 1 X

R58186 CLAMP 1 X

R71212 CLAMP 1 X

R74804 CLAMP 1 X

R71398 SCREW 1 X

R61145 STRAP 1 X

R120182 STRAP 1 X

10 21H1463 CAP SCREW 1 X 0.190" X 7/8"

R59297 HALF CLAMP 2 X

R59598 GASKET 2 X

11 RE55662 ABSORBER 1 X

12 24H1884 WASHER 1 X 13/32" X 13/16" X 0.120" 13/32" X

13/16" X 0.120", (NLR)

13 19M7166 CAP SCREW 1 X M10 X 20 M10 X 20

14 RE61593 INJECTION NOZZLE 6 X (A) (ROBERT BOSCH)

R51603 O-RING 6 X

15 R84472 WASHER 6 X 7.360 X 18.160 X 2 MM (0.290" X 0.715"

X 0.079") 7.360 X 18.160 X 2 MM

(0.290" X 0.715" X 0.079")

16 R504057 O-RING 6 087550- X

17 RE501970 ADAPTER 6 087550- X

18 R79604 TUBE NUT 6 087550- X

19 R51937 TUBE NUT 1 X

20 AR85519 PLUG 1 X

21 RE500803 FUEL LINE 1 087550- X

22 R77551 O-RING 6 -087549 X

23 R87082 FITTING 6 -087549 X

24 R79604 TUBE NUT 6 -087549 X

25 R79605 WASHER 6 -087549 X

26 R79606 TEE FITTING 6 -087549 X

27 R51936 SEALING WASHER 11 -087549 X

28 RE15807 FUEL LINE 2 -087549 X

29 RE15808 FUEL LINE 2 -087549 X

30 RE36421 FUEL LINE 2 -087549 X

31 R97061 TEE FIT, TING 1 -087549 X

(A) 1 ORANGE DOT

(1) POINT ORANGE

(1) ORANGEFARBENER PUNKT

(1) PUNTO ARANCIONE

(1) PUNTO ANARANJADO

(1) ORANGEFAERGAD PUNKT

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska