详细描述

约翰迪尔伐木归堆机/伐木装载机应用的发动机零件

设备型号

备注

643

(no special remarks)

953 G

High Compression Piston. To ESN 199,999. Tier 1

853JH

Piston (m) RE527039 Tier 2 & Tier 3

753 JH

High Compression Piston. To ESN 199,999. Tier 1

643D

(no special remarks)

535

High Compression Piston. To ESN 199,999. Tier 1

903J

Piston (m) RE527039 Tier 2 & Tier 3

759 G

High Compression Piston. To ESN 199,999. Tier 1

693D

(no special remarks)

530 B

High Compression Piston. To ESN 199,999. Tier 1

903JH

Piston (m) RE527039 Tier 2 & Tier 3

759 J

High Compression Piston. To ESN 199,999. Tier 1

643

Liter designated

3554

High Compression Piston. To ESN 199,999. Tier 1

909J

Piston (m) RE527039 Tier 2 & Tier 3

759 JH

High Compression Piston. To ESN 199,999. Tier 1

643D

Liter designated

909JH

Piston (m) RE527039 Tier 2 & Tier 3

850

High Compression Piston. To ESN 199,999. Tier 1

653

Liter designated

953J

Piston (m) RE527039 Tier 2 & Tier 3

853 G

High Compression Piston. To ESN 199,999. Tier 1

693D

Liter designated

959J

Piston (m) RE527039 Tier 2 & Tier 3

High Compression Piston. To ESN 199,999. Tier 1

693C

From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

608 L

High Compression Piston. To ESN 199,999. Tier 1

900

High Compression Piston. To ESN 199,999. Tier 1

643G

Piston (m) RE55512, RE505102

608 S

High Compression Piston. To ESN 199,999. Tier 1

903 G

High Compression Piston. To ESN 199,999. Tier 1

843G

Piston (m) RE55512, RE505102

753 G

High Compression Piston. To ESN 199,999. Tier 1

950

High Compression Piston. To ESN 199,999. Tier 1

853J

Piston (m) RE527039 Tier 2 & Tier 3

753 J

High Compression Piston. To ESN 199,999. Tier 1

约翰迪尔伐木归堆机/伐木装载机应用的发动机零件

| 设备型号 | 备注 |

|---|---|

| 643 | (no special remarks) |

| 953 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 853JH | Piston (m) RE527039 Tier 2 & Tier 3 |

| 753 JH | High Compression Piston. To ESN 199,999. Tier 1 |

| 643D | (no special remarks) |

| 535 | High Compression Piston. To ESN 199,999. Tier 1 |

| 903J | Piston (m) RE527039 Tier 2 & Tier 3 |

| 759 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 693D | (no special remarks) |

| 530 B | High Compression Piston. To ESN 199,999. Tier 1 |

| 903JH | Piston (m) RE527039 Tier 2 & Tier 3 |

| 759 J | High Compression Piston. To ESN 199,999. Tier 1 |

| 643 | Liter designated |

| 3554 | High Compression Piston. To ESN 199,999. Tier 1 |

| 909J | Piston (m) RE527039 Tier 2 & Tier 3 |

| 759 JH | High Compression Piston. To ESN 199,999. Tier 1 |

| 643D | Liter designated |

| 909JH | Piston (m) RE527039 Tier 2 & Tier 3 |

| 850 | High Compression Piston. To ESN 199,999. Tier 1 |

| 653 | Liter designated |

| 953J | Piston (m) RE527039 Tier 2 & Tier 3 |

| 853 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 693D | Liter designated |

| 959J | Piston (m) RE527039 Tier 2 & Tier 3 |

| High Compression Piston. To ESN 199,999. Tier 1 | |

| 693C | From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558 |

| 608 L | High Compression Piston. To ESN 199,999. Tier 1 |

| 900 | High Compression Piston. To ESN 199,999. Tier 1 |

| 643G | Piston (m) RE55512, RE505102 |

| 608 S | High Compression Piston. To ESN 199,999. Tier 1 |

| 903 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 843G | Piston (m) RE55512, RE505102 |

| 753 G | High Compression Piston. To ESN 199,999. Tier 1 |

| 950 | High Compression Piston. To ESN 199,999. Tier 1 |

| 853J | Piston (m) RE527039 Tier 2 & Tier 3 |

| 753 J | High Compression Piston. To ESN 199,999. Tier 1 |

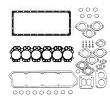

约翰迪尔 6081 高压缩活塞

约翰迪尔(John Deere) 强鹿6081柴油发动机高压缩活塞大修包TOK504201

型号

数量

描述

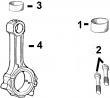

TAR49025

1

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR66452

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR74008

6

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套

TR87561

4

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506220

1

约翰迪尔(John Deere) 强鹿6081发动机大修包

TRE520036

1

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR

TRE64509

6

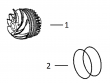

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

约翰迪尔(John Deere) 强鹿6081柴油发动机大修包TOK504201A

型号

数量

描述

TAR49025

1

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR501035

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR74008

6

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套

TR87561

4

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506220

1

约翰迪尔(John Deere) 强鹿6081发动机大修包

TRE520036

1

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR

TRE64509

6

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

约翰迪尔(John Deere) 强鹿6081柴油发动机内部修理套件TIK504201

型号

数量

描述

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR66452

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR71918

1

约翰迪尔(John Deere) 强鹿6081发动机GASKET, OIL PAN

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506222

1

约翰迪尔(John Deere) 强鹿6081发动机GASKET, CYL HEAD SET

TRE64509

6

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

型号

数量

描述

TAR49025

1

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR66452

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR74008

6

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套

TR87561

4

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506220

1

约翰迪尔(John Deere) 强鹿6081发动机大修包

TRE520036

1

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR

TRE64509

6

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

型号

数量

描述

TAR49025

1

约翰迪尔(John Deere) 强鹿6081发动机后油封/ WITH WEAR SLEEVE

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR501035

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR74008

6

约翰迪尔(John Deere) 强鹿6081发动机连杆衬套

TR87561

4

约翰迪尔(John Deere) 强鹿6081发动机凸轮轴衬套

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506220

1

约翰迪尔(John Deere) 强鹿6081发动机大修包

TRE520036

1

约翰迪尔(John Deere) 强鹿6081发动机SEAL, 曲轴 REAR

TRE64509

6

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

型号

数量

描述

TR116081

6

约翰迪尔(John Deere) 强鹿6081发动机连杆瓦(标准

TR66452

12

约翰迪尔(John Deere) 强鹿6081发动机连杆螺钉

TR71918

1

约翰迪尔(John Deere) 强鹿6081发动机GASKET, OIL PAN

TRE529319

6

约翰迪尔(John Deere) 强鹿6081发动机主轴瓦(标准)

TRE529320

1

约翰迪尔(John Deere) 强鹿6081发动机止推瓦(标准)

TRE506222

1

约翰迪尔(John Deere) 强鹿6081发动机GASKET, CYL HEAD SET

TRE64509

6

约翰迪尔(John Deere) 强鹿6081发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈

|

| |||||||||||||||||||||||||||

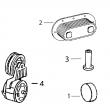

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

(3)用铝油盘使用TR49377(RE504822)。

(4)使用TR66452杆式螺栓和机器分体式连杆,并使用带断裂分体式连杆的TR501035杆式螺栓。

(5)发动机ESN 199,999及以下。 仅适用于Exaust Valves。

(6)发动机ESN 200,000及以上。 仅适用于Exaust Valves。

(7)发动机ESN 199,999及以下。

(8)发动机ESN 200,000及以上。

(9)检查应用程序是否正确使用。

(10)机器分体连杆。 使用棒螺栓TR66452。

(11)破裂的分裂连杆。 使用棒螺栓TR501035。

(12)高流量。

(13)与断裂分体连杆一起使用。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE59754、RE507284、RE59754、RE519626、RE508202、RE58935、T19044、RE62418、RE62419、RE521248、RE520842、C085004、RE522878、RE196945、RE191915、RE522688、RE522687、RE519774、RE532628、RE507980、RE531703、RE24619、RE187966、RE205726、RE507264、RE504836、RE509036ouo1004,0000cb2 –19–08jan01–1/1 level 6 ecu - dtc spn 637 fmi 8 crank position input missing - continued – – –1/1 level 6 ecu - dtc spn 637 fmi 8 crank position input missing diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the crank position sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 195 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make notes of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 637 fmi 8 reoccurs: go to 2 spn 637 fmi 8 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 crank sen*** observable test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition off 2. remove crank position sen*** from timing gear cover 3. inspect sen*** tip for damage, such as cracks/debris no signs of damage: go to 3 damage to sen***: determine&repair the cause of damage to sen*** replace sen*** and retest – – –1/1 3 crank sen*** depth test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. check depth of crank sen***. see check crankshaft position sen*** depth in ctm100, section 04 group 150. depth ok: go to 4 depth out of specification: repair as needed. ctm188 (20mar01) 04-160-195 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=383 trouble code diagnostics&tests – – –1/1 4 crank position sen*** test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition off 2. disconnect crank position sen*** connector 3. using a multimeter, measure resistance between both terminals of the crank position sen*** measurement between 2500&3500 ohms: go to 5 measurement below 2500 ohms/above 3500 ohms: faulty crank position sen***. 04 160 196 – – –1/1 5 open in crank position sen*** input and return wire test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition off 2. disconnect crank position sen*** connector 3. disconnect 60-way ecu connector 4. using a multimeter, measure resistance between: ? terminal a of the crank position sen*** harness connector&terminal x2 in the harness end of the 60-way ecu connector ? terminal b of the crank position sen*** harness connector&terminal w3 in the harness end of the 60-way ecu connector both measurements 5 ohms/less: go to 6 either measurement greater than 5 ohms: open in crank position sen*** input wire or open in crank position sen*** return wire or terminals a&b in the crank position sen*** harness connector possibly inverted – – –1/1 6 crank position sen*** input wiring harness test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition off 2. crank position sen*** connector&60-way ecu connector still disconnected 3. using a multimeter measure resistance between terminal x2 in the harness end of the 60-way ecu connector and: ? a good ground ? all other terminals in both ecu connectors all measurements greater than 2000 ohms: go to 7 any measurement less than 2000 ohms: faulty crank position sen*** input wiring harness ctm188 (20mar01) 04-160-196 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=384 trouble code diagnostics&tests 04 160 197 – – –1/1 7 crank position sen*** return wiring harness test note: for wiring&theory of operation information, see dtc spn 637 fmi 8 crank position input missing supporting information. 1. ignition off 2. crank position sen*** connector&60-way ecu connector still disconnected 3. using a multimeter measure resistance between terminal w3 in the harness end of the 60-way ecu connector and: ? a good ground ? all other terminals in both ecu connectors all measurements greater than 2000 ohms: faulty crank position sen*** connector or damaged crank position sen*** or faulty ecu connector or faulty ecu any measurement less than 2000 ohms: faulty crank position sen*** return wiring harness ctm188 (20mar01) 04-160-197 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=385 trouble code diagnostics&tests 04 160 198 dpsg,rg40854,222 –19–21nov00–1/1 level 6 ecu - dtc spn 637 fmi 10 crank position input pattern error rg10401 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. crank position sen*** ? the crank position sen*** is an inductive type pickup sen*** that detects notches on the crank timing wheel. the ecu uses the crank position input to determine engine speed&precision piston position in relation to tdc. the ecu using the dst, monitors the cam position sen*** input to determine piston position in relation to the firing order. based on information from the crank&cam position sen***s, the ecu calculates the cam position sen***s, the ecu calculates the correct start of injection&amount of fuel to inject, then commands the euis accordingly. dtc spn 637 fmi 10 will set if: ? the ecu detects an improper pattern on the crank position input. if dtc spn 637 fmi 10 sets, the following will occur: ? if a cam position sen*** trouble code accompanies dtc spn 637 fmi 10, the engine will die&won’t restart until at least one of the two codes is repaired. ? ecu will use only the cam position sen*** input to determine piston position. ? the moment that the trouble codes sets, the engine may hesitate/die, but it will re-start. ? prolonged cranking time may be required to start the engine. ctm188 (20mar01) 04-160-198 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=386 trouble code diagnostics&tests ouo1004,0000cb3 –19–08jan01–1/1 level 6 ecu - dtc spn 637 fmi 10 crank position input pattern error - continued – – –1/1 level 6 ecu - dtc spn 637 fmi 10 crank position input pattern error diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 60-way ecu connector and the crank position sen*** connector looking for dirty, damaged,/poorly positioned terminals. 04 160 199 – – –1/1 1 intermittent fault test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make notes of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 637 fmi 10 reoccurs: go to 2 spn 637 fmi 10 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 crank position sen*** test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. 1. ignition off 2. disconnect crank position sen*** connector 3. using a multimeter, measure resistance between both terminals of the crank position sen*** measurement between 2500&3500 ohms: go to 3 measurement below 2500 ohms/above 3500 ohms: faulty crank position sen*** ctm188 (20mar01) 04-160-199 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=387 trouble code diagnostics&tests 04 160 200 – – –1/1 3 crank position wiring open test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. 1. ignition off 2. disconnect crank position sen*** connector disconnect 60-way ecu connector 3. using a multimeter, measure resistance between: ? terminal a of the crank position sen*** harness connector&terminal x2 in the harness end of the 60-way ecu connector. ? terminal b of the crank position sen*** harness connector&terminal w3 in the harness end of the 60-way ecu connector. both measurements 5 ohms/less: go to 4 either measurement greater than 5 ohms: open in crank position sen*** input wire or open in crank position sen*** return wire or terminals a&b in the crank position sen*** harness connector possibly inverted – – –1/1 4 crank position sen*** return wiring harness test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. 1. ignition off 2. disconnect crank position sen*** connector 3. disconnect 60-way ecu connector 4. using a multimeter, measure resistance between: ? terminal a of the crank position sen*** harness connector&terminal x2 in the harness end of the 60-way ecu connector. ? terminal b of the crank position sen*** harness connector&terminal w3 in the harness end of the 60-way ecu connector. all measurements greater than 2000 ohms: go to 5 any measurement less than 2000 ohms: faulty crank position sen*** return wiring harness – – –1/1 5 crank sen*** observable test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. note: do not remove the timing cover to perform this inspection. 1. remove crank sen*** from timing gear cover 2. inspect sen*** for cracks, corrosion,/any foreign material on the end of the sen*** 3. using a mirror&a flashlight, inspect the crankshaft timing wheel all components ok: go to 6 fault found in a component: repair/replace component as needed. ctm188 (20mar01) 04-160-200 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=388 trouble code diagnostics&tests – – –1/1 6 crank sen*** depth test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. check depth of the crank sen***. see check crankshaft position sen*** depth in ctm100, section 04, group 150 depth ok: go to 7 depth out of specification: repair as needed. 04 160 201 – – –1/1 7 cam to crank timing test note: for wiring&theory of operation information, see dtc spn 637 fmi 10 crank position input pattern error supporting information. 1. ignition off 2. check cam to crank timing. see check camshaft-to-crankshaft timing in ctm100, section 02, group 050. crank timing pin engages in slot: faulty crank sen*** connector or faulty ecu connector or faulty ecu crank timing pin won’t engage slot: adjust timing between cam&crank. see check&adjust camshaft-to- crankshaft timing in section 02, group 050 of ctm100 ctm188 (20mar01) 04-160-201 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=389 trouble code diagnostics&tests 04 160 202 rg40854,0000015 –19–03jan01–1/1 level 6 ecu - dtc spn 639 fmi 13 can error rg10656 –19–19dec00 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. controller area network (can) ? can is the network in which the individual controllers on a machine communicate with each other. the number of controllers communicating on can depends on the application. on some applications, the ecu is the only controller on can; on other applications, there are many controllers on can. dtc spn 639 fmi 13 will set if: ? the ecu detects a problem communicating on can. if dtc spn 639 fmi 13 sets, the following will occur: ? depending on the application, engine operation may or may not be effected. ctm188 (20mar01) 04-160-202 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=390 trouble code diagnostics&tests rg40854,000006f –19–04feb01–1/1 level 6 ecu - dtc spn 639 fmi 13 can error - continued – – –1/1 level 6 ecu - dtc spn 639 fmi 13 can error diagnostic procedure 04 160 203 – – –1/1 1 intermittent fault test note: for theory of operation information, see dtc spn 639 fmi 13 can error supporting information 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of all dtcs, then clear all dtcs 4. ignition on 5. using the dst, monitor dtcs on the active code display parameter dtc spn 639 fmi 13 reoccurs: go to 2 dtc spn 639 fmi 13 cleared: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. – – –1/1 2 check other controllers for can related dtcs if application has other machine controllers communicating on the can bus, check those controllers?for can related dtcs no can related dtcs found on other controllers: go to 3 did find can related dtcs on other controllers: refer to machine manual to diagnose&repair the cause of dtc, then determine if dtc spn 639 fmi 13 reoccurs – – –1/1 3 can resistance test note: for theory of operation information, see dtc spn 639 fmi 13 can error supporting information 1. ignition off 2. disconnect 60-way ecu?connector 3. using a multimeter, measure resistance between?terminals b1&b2 in the harness end of the 60-way ecu connector between 55 - 65 ohms: faulty 60-way ecu connector or faulty ecu less than 55/greater than 65 ohms: open/short in can communication circuit ctm188 (20mar01) 04-160-203 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=391 trouble code diagnostics&tests 04 160 204 dpsg,rg40854,223 –19–30jun99–1/1 level 6 ecu - dtc spn 651 fmi 5 cylinder #1 eui circuit open rg10386 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 651 fmi 5 will set if: ? the ecu detects an open in the cylinder #1 eui circuit. if dtc spn 651 fmi 5 sets, the following will occur: ? cylinder #1 eui will not fire. ctm188 (20mar01) 04-160-204 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=392 trouble code diagnostics&tests ouo1004,0000cb4 –19–08jan01–1/1 level 6 ecu - dtc spn 651 fmi 5 cylinder #1 eui circuit open - continued 04 160 205 – – –1/1 level 6 ecu - dtc spn 651 fmi 5 cylinder #1 eui circuit open diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the back of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3, spn 611 fmi 4,/spn 627 fmi 1 are active, repair those dtcs first. note: for wiring&theory of operation information, see dtc spn 651 fmi 5 cylinder #1 eui circuit open supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 651 fmi 5 reoccurs: go to 2 spn 651 fmi 5 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-205 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=393 trouble code diagnostics&tests 04 160 206 – – –1/1 2 open wire in 90v supply/eui control wire test note: for wiring&theory of operation information, see dtc spn 651 fmi 5 cylinder #1 eui circuit open supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running. 2. disconnect eui wiring harness connector at rear of cylinder head disconnect 18-terminal half of 48-way ecu connector 3. using a multimeter, measure resistance between: ? terminal h in the harness end of the eui wiring harness connector&terminal a2 in the harness end of the ecu connector. ? terminal c in the harness end of the eui wiring harness connector&terminal c3 in the harness end of the ecu connector. both measurements 5 ohms/less: go to 3 measurement between h to a2 greater than 5 ohms: open in wire between terminal h&a2. measurement between c to c3 greater than 5 ohms: open in wire between terminal c&c3. – – –1/1 3 cylinder 1 eui test note: for wiring&theory of operation information, see dtc spn 651 fmi 5 cylinder #1 eui circuit open supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 1 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 1 eui ? the two terminals on the known good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the affects of temperature. typically, eui resistance should be 1.0-1.8 ohms. difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 1 eui ctm188 (20mar01) 04-160-206 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=394 trouble code diagnostics&tests 04 160 207 遂宁JohnDeere水泵RE530194价格行情,湛江JOHNDEERE强鹿3029DF128配件的价格,汕头美国JohnDeere机油泵RE527933市场报价,德宏强鹿凸轮轴塞R82007供应商,榆林johndeere约翰迪尔强鹿柴油发动机燃油泵RE533095厂家供应,九龙约翰迪尔发动机曲轴代理,拉萨强鹿柴油机主轴瓦RE65165代理商,克孜勒苏约翰迪尔柴油发电机组进排气门多少钱,龙岩约翰迪尔挖掘机发电机哪家买,那曲约翰迪尔9420R拖拉机发动机配件批发,九龙强鹿柴油机3029连杆铜套供应商,邯郸约翰迪尔进气门R97490公司,池州强鹿修理包RE527551找哪家,本溪强鹿机滤RE509672批发价,和田JOHNDEERE强鹿4045TFM缸套活塞组件批发,东营强鹿柴油滤芯RE532952公司,宜昌约翰迪尔6090柴油机排气门找哪家,镇江JOHNDEERE强鹿4045TF275配件找哪家,成都约翰迪尔发动机大修包TRE532715价格行情,周口美国强鹿3029DF128滤清器RE60021厂家供应,常德约翰迪尔6090柴油机水泵多少钱,重庆约翰迪尔RE30250批发商,福州约翰迪尔PowerTech?发动机配件诚信推荐,岳阳JohnDeere进气门导管R121193批发商,吕梁johndeere约翰迪尔强鹿柴油发动机缸垫R116516厂家批发,阿拉善约翰迪尔气门室盖垫片R524497供货商,包头约翰迪尔发动机风扇叶供货商,珠海JohnDeere加大主轴瓦RE65165B批发价,长沙约翰迪尔甘蔗机发动机配件一级代理,中卫强鹿滤芯滤清器RE500186诚信推荐,德宏JohnDeere齿环R28811一级代理,昆明强鹿6081发动机止推轴承瓦一级代理,黄山约翰迪尔发动机喷油咀公司,铜川约翰迪尔强鹿气门锁夹找哪家,宜宾强鹿传感器RE167207哪家买,台中强鹿曲轴RE506195代理商,内江约翰迪尔强鹿4045柴油机平衡轴铜套代理,林芝约翰迪尔排气门RE518081哪家好,达州JohnDeere电子燃油泵AL155607厂家供货,香港岛强鹿RE44574曲轴后油封诚信推荐,克拉玛依约翰迪尔拖拉机发动机气缸垫哪家好,周口美国强鹿3029DF128滤清器RE60021供应商,六安JohnDeere凸轮轴铜衬套R527877厂家供货,海西约翰迪尔柴油机排气门导管R119132厂家价格,新疆约翰迪尔活塞RE529264公司,双鸭山强鹿6081柴油发动机机油底壳垫片厂家价格,1/1 4 eui harness in cylinder head test note: for wiring&theory of operation information, see dtc spn 651 fmi 5 cylinder #1 eui circuit open supporting information. 1. ignition off 2. cylinder 1 eui wires disconnected from eui 3. disconnect eui wiring harness connector from rear of cylinder head 4. using a multimeter, measure resistance between: ? one of the cylinder 1 eui harness eyelet&the corresponding terminal at the connector on the rear of the cylinder head (either c/h, the eui’s are not polarity sensitive) ? the other cylinder 1 eui harness eyelet&the other corresponding terminal at the connector on the rear of the cylinder head both measurements 2.0 ohms/less: faulty ecu connection or faulty eui wiring harness connection or faulty ecu either measurements greater than 2.0 ohms: faulty eui harness in head ctm188 (20mar01) 04-160-207 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=395 trouble code diagnostics&tests 04 160 208 dpsg,rg40854,224 –19–30jun99–1/1 level 6 ecu - dtc spn 651 fmi 6 cylinder #1 eui circuit shorted rg10386 –19–23nov99 important: do not force probes into connector terminals/damage will result. use jt07328 connector adapter test kit to make measurements in connectors. this will ensure that terminal damage does not occur. eui (electronic unit injector) ? the fuel in 10.5 l&12.5 l engines is delivered by 6 (one for each cylinder) electronic unit injectors (euis). the euis are mounted in they cylinder head, under the valve cover, so that they spray directly into the center of the cylinder bore. each eui is an injection pump&injector combined, operating at much higher pressures than standard in-line or rotary injection pumps. the ecu controls the start of injection&the amount of fuel injected by turning the solenoid in the eui valve housing on&off which in turn opens&closes the eui spill valve. ? power is supplied to the euis for cylinders 1, 2, and 3 by a common wire,&to the euis for cylinders 4, 5,&6 by a different common wire. the ecu energizes&deenergizes the solenoids of individual euis by closing&opening the individual eui ground circuits. dtc spn 651 fmi 6 will se, t if: ? the ecu detects a short in the cylinder #1 eui circuit. if dtc spn 651 fmi 6 sets, the following will occur: ? cylinder #1 eui will not fire. ctm188 (20mar01) 04-160-208 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=396 trouble code diagnostics&tests ouo1004,0000cb5 –19–08jan01–1/1 level 6 ecu - dtc spn 651 fmi 6 cylinder #1 eui circuit shorted - continued 04 160 209 – – –1/1 level 6 ecu - dtc spn 651 fmi 6 cylinder #1 eui circuit shorted diagnostic procedure note: before using this diagnostic procedure, perform a preliminary inspection of the 48-way ecu connector and the eui harness connector (located at the rear of the cylinder head) looking for dirty, damaged,/poorly positioned terminals. – – –1/1 1 intermittent fault test important: if dtcs spn 611 fmi 3, spn 611 fmi 4,/spn 627 fmi 1 are active, repair those dtcs first. note: for wiring&theory of operation information, see dtc spn 651 fmi 6 cylinder #1 eui circuit shorted supporting information. 1. ignition on, engine off 2. using the dst, monitor dtcs on the active code display parameter 3. make note of any dtcs, then clear all dtcs 4. ignition on, engine running 5. using the dst, monitor dtcs on the active code display parameter spn 651 fmi 6 reoccurs: go to 2 spn 651 fmi 6 doesn’t reoccur: problem is intermittent. if no other codes are present, see intermittent fault diagnostics, earlier in this group. ctm188 (20mar01) 04-160-209 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=397 trouble code diagnostics&tests 04 160 210 – – –1/1 2 short in eui wiring harness test note: for wiring&theory of operation information, see dtc spn 651 fmi 6 cylinder #1 eui circuit shorted supporting information. 1. ignition off caution: possible strong electric shock hazard if engine is cranking or running. 2. disconnect 18-terminal half of 48-way ecu connector 3. disconnect eui wiring harness connector at rear of cylinder head 4. using a multimeter, measure resistance between terminal h in the harness end of the eui wiring connector and: ? terminal c in the harness end of the eui wiring connector ? terminal f in the harness end of the eui wiring connector both measurements greater than 20,000 ohms: go to 3 either measurement less than 20,000 ohms: short in ecu wiring harness. – – –1/1 3 cylinder 1 eui test note: for wiring&theory of operation information, see dtc spn 651 fmi 6 cylinder #1 eui circuit shorted supporting information. 1. remove rocker arm cover 2. disconnect electrical connections to cylinder 1 eui&a known good eui 3. using a multimeter measure resistance between: ? the two terminals on cylinder 1 eui ? the two terminals on the known good eui 4. compare the measurements between the two euis note: because eui resistance varies with temperature, a comparison is used to compensate for the affects of temperature. typical eui resistance should be 1.0-1.8 ohms. 湛江强鹿滤芯滤清器RE62424批发价,延边约翰迪尔6068柴油机四配套厂家供货,贵港JohnDeere柴油机缸套R530609批发商,厦门强鹿连杆瓦RE529318厂家供货,通辽约翰迪尔强鹿3029柴油机曲轴位置传感器供应商,忻州约翰迪尔柴油机气门锁夹T20077的价格,东莞强鹿曲轴齿轮R114282多少钱,广安约翰迪尔节温器RE522076批发价,铜川johndeere约翰迪尔强鹿柴油发动机气门座圈批发价,遵义约翰迪尔?Johndeere活塞组件?RE61467价格行情,常德约翰迪尔柴油机小修包IK6090价格,绵阳约翰迪尔强鹿气缸室盖垫片R527884代理,苏州强鹿柴油发动机活塞环RE503528批发价,丹东约翰迪尔空气加热器el502668供货商,difference between measurements 0.2 ohms/less: go to 4 difference between measurements greater than 0.2 ohms: faulty cylinder 1 eui – – –1/1 4 eui wiring harness in cylinder head test cylinder 1 eui test note: for wiring&theory of operation information, see dtc spn 651 fmi 6 cylinder #1 eui circuit shorted supporting information. 1. ignition off 2. keep cylinder 1 eui wires disconnected from eui 3. keep eui wiring har, ness connector at rear of cylinder head disconnected 4. using a multimeter, measure resistance between both of cylinder 1 eui harness eyelets. greater than 20,000 ohms: faulty ecu connection or faulty eui wiring harness connection or faulty ecu less than 20,000 ohms: faulty eui wiring harness ctm188 (20mar01) 04-160-210 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=398 trouble code diagnostics&tests 04 160 211 ctm188 (20mar01) 04-160-211 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=399 trouble code KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R60914 SET SCREW 1 X

2 R53918 PACKING 1 X

3 T31556 NUT 1 X

4 R68715 PIN 1 X

5 AR89339 SEAL 1 X

6 AR89578 LEVER 1 X

7 24M7054 WASHER 1 X 6.400 X 12 X 1.600 MM

8 T24229 LOCK WASHER 2 X

9 R68716 NUT 1 X

10 R112128 LEVER 1 X (A) (B) (ROBERT BOSCH)

11 19M8826 SCREW 2 X M6 X 16

12 14H786 NUT 1 X 1/4"

13 24H1287 WASHER 1 X 9/32" X 5/8" X 0.065"

14 R67143 FITTING 1 X

15 22H1062 SET SCREW 1 X 0.164" X 1/2"

16 R67142 WASHER 1 X

17 R53976 SCREW 1 X

18 R54880 LOCK WASHER 2 X

19 AR89552 LEVER 1 X (C)

20 19H1948 CAP SCREW 1 X 1/4" X 3/4"

21 R68438 RETAINER 1 X

22 R53955 O-RING 1 X

(A) THROTTLE (B) NOT AS ILLUSTRATED (C) SHUT-OFF

MANETTE DES GAZ DIFFERENT DE L’ILLUSTRATION ROBINET D’ARRET

DROSSELKLAPPE NICHT GEMAESS ABBILDUNG ABSCHALTUNG

ACCELERATORE NON COME ILLUSTRATO RUBINETTO D’ARRESTO

ACELERADOR DIFIERE DE LA ILUSTRACION GRIFO DECIERRE

GASREGLAGE EJ SOM VISAD AVSTAENGING

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 21H1319 SCREW 1 X 0.164" X 7/8"

2 12H315 LOCK WASHER 1 X 0.164"

3 24H1136 WASHER 2 X 11/32" X 11/16" X 0.065"

4 19H1900 CAP SCREW 2 X 5/16" X 3/4"

5 R99930 BRACKET 1 X (A)

6 R104675 CLIP 1 X

7 14H605 NUT 1 X 0.164"

8 R104592 PIPE PLUG 1 X

9 R128694 BASE 1 X (SUB FOR R127415) (ALSO ORDER (2)

R104592)

(A) SHUT-OFF

ROBINET D’ARRET

ABSCHALTUNG

RUBINETTO D’ARRESTO

GRIFO DECIERRE

AVSTAENGING

KEY PART NO. PART NAME QTY OR PUMP DATE F F F REMARKS

1 R63059 SPRING 1 X

2 R63060 PISTON 1 X

3 R67886 O-RING 1 X

4 R67885 HOUSING 1 X

5 R63063 SCREW 2 X

6 R54880 LOCK WASHER 2 X

7 R62104 VALVE 1 X

8 R62105 PIN FASTENER 1 X

9 R26373 SPRING 1 X

10 R62107 WASHER 2 X

11 R62106 SCREW 1 X

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska