详细描述

Specifications

1104D-E44T and 1104D-E44TA

Industrial Engines

NP (Engine)

NR (Engine)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

UENR4460

3

Table of Contents

Table of Contents

Crankshaft Pulley ...................... ..................... 34

Belt Tensioner......................... ........................ 34

Refrigerant Compressor................. ................ 35

Fan Drive............................ ............................ 35

Engine Lifting Bracket................... .................. 35

Alternator............................ ............................ 36

Starter Motor.......................... ......................... 36

Coolant Temperature Sensor............. ............. 37

Engine Oil Pressure Sensor.............. ............. 37

Boost Pressure Sensor.................. ................. 38

Inlet Manifold Temperature Sensor......... ........ 38

Speed/Timing Sensor................... .................. 38

Electronic Control Module ............... ............... 39

Glow Plugs .......................... ........................... 39

SpecificationsSection

Engine Design ......................... ......................... 4

Fuel Injection Lines...................... ..................... 4

Fuel Injection Pump..................... ..................... 5

Fuel Injectors.......................... .......................... 7

Fuel Filter Base (Twin Secondary Fuel Filter

Base) ............................... ............................... 8

Fuel Priming Pump (Mechanical Priming

Pump) ............................... .............................. 8

Fuel Priming Pump (Electric Fuel Priming

Pump) ............................... .............................. 9

Fuel Manifold (Rail)...................... ..................... 9

Lifter Group........................... .......................... 10

Rocker Shaft.......................... ......................... 10

Valve Mechanism Cover................. ................ 12

Cylinder Head Valves ................... .................. 12

Cylinder Head......................... ........................ 13

Turbocharger......................... ......................... 14

Exhaust Manifold...................... ...................... 15

Camshaft............................ ............................ 16

Camshaft Bearings..................... .................... 16

Engine Oil Filter Base................... .................. 17

Engine Oil Cooler...................... ...................... 18

Engine Oil Pump....................... ...................... 19

Engine Oil Pressure.................... .................... 21

Engine Oil Bypass Valve ................ ................ 21

Engine Oil Pan........................ ........................ 22

Crankcase Breather.................... .................... 23

Water Temperature Regulator and Housing.. . 24

Water Pump.......................... .......................... 24

Cylinder Block......................... ........................ 25

Crankshaft (Spheroidal Graphite Iron (SGI)

Index Section

Index................................ ............................... 41

Crankshaft).......................... ......................... 26

Crankshaft Seals ...................... ...................... 26

Connecting Rod Bearing Journal (Spheroidal

Graphite Iron Crankshaft)............... .............. 27

Main Bearing Journal (Spheroidal Graphite Iron

(SGI) Crankshaft)..................... ..................... 27

Connecting Rod (For Use With Spheroidal

Graphite Iron (SGI) Crankshaft).......... .......... 27

Piston and Rings ...................... ...................... 29

Piston Cooling Jet...................... ..................... 30

Balancer .......................................................... 30

Front Housing and Covers............... ............... 31

Gear Group (Front)..................... .................... 32

Flywheel .......................................................... 33

Flywheel Housing...................... ..................... 33

This document has been printed from SPI2. NOT FOR RESALE.

![]()

4

UENR4460

Specifications Section

SpecificationsSection

When the crankshaft is viewed from the front of the

engine, the crankshaft rotates in the following

direction: .....................................................Clockwise

i02657590

Engine Design

When the camshaft is viewed from the front of the

engine, the camshaft rotates in the following direction:

.....................................................................Clockwise

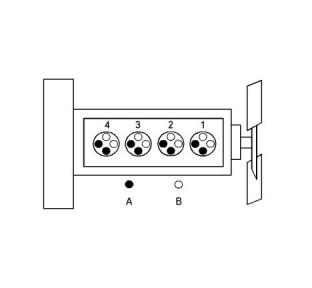

The front of the engine is opposite the flywheel end.

The left side and the right side of the engine are

viewed from the flywheel end. The No. 1 cylinder is

the front cylinder.

i05535328

Fuel Injection Lines

Contact with high pressure fuel may cause fluid

penetration and burn hazards. High pressure fuel

spray may cause a fire hazard. Failure to follow

these inspection, maintenance and service in-

structions may cause personal injury or death.

Refer to Operation and Maintenance Manual,

“General Hazard Information and High Pressure Fuel

Lines” before adjustments and repairs are performed.

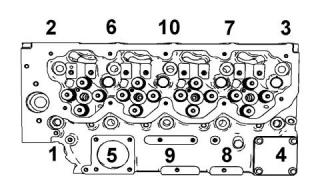

Illustration 1

g01335181

Cylinder and valve location

NOTICE

(A) Exhaust valve

(B) Inlet valve

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

Bore ............................................105 mm (4.133 inch)

Stroke .........................................127 mm (5.000 inch)

Displacement........................................4.4 L (269 in3)

Cylinder arrangement ........................................In-line

Type of combustion ..............................Direct injection

Compression ratio

Ensure that all adjustments and repairs are

performed by authorized personnel that have had the

correct training.

Turbocharged engines and turbocharged

aftercooled engines ....................................16.2:1

Number of cylinders .................................................. 4

Valves per cylinder .................................................... 4

Valve lash

Inlet valve..........................0.35 mm (0.0138 inch)

Exhaust valve....................0.35 mm (0.0138 inch)

Firing order .....................................................1, 3, 4, 2

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

5

Specifications Section

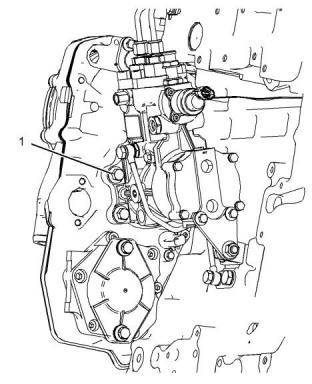

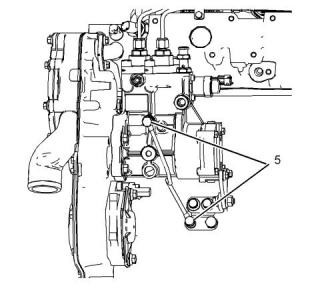

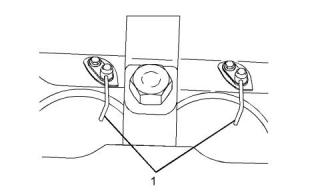

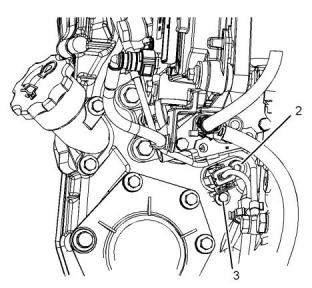

Illustration 2

g03506656

Typical example

(1) (2) Tighten the nuts on the fuel injection lines to

the following torque.............................32 N·m (24 lb ft)

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

(3) Tighten the screw to the following torque.

............................................................22 N·m (16 lb ft)

(4) Tighten the screws for the clamps to the following

torque...................................................4 N·m (35 lb in)

i05547015

Fuel Injection Pump

Note: The timing of the fuel injection pump will need

to be checked by trained personnel. In order to check

the timing of the fuel injection pump, refer to Systems

Operation, Testing and Adjusting, “Fuel Injection

Pump Timing - Check”.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

6

UENR4460

Specifications Section

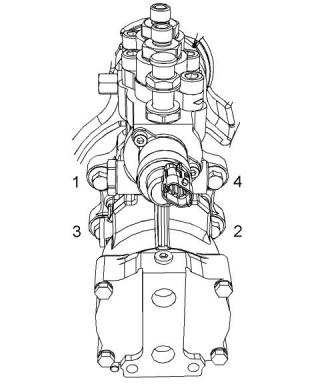

Illustration 3

g03543157

Illustration 4

g03346360

Typical example

Typical example

(1) Tighten the bolts to an initial torque.............10 N·m

(89 lb in)

Tighten the bolts in the sequence that is in illustration

4 . Tighten the bolts to the following torque......44 N·m

(32 lb ft)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

7

Specifications Section

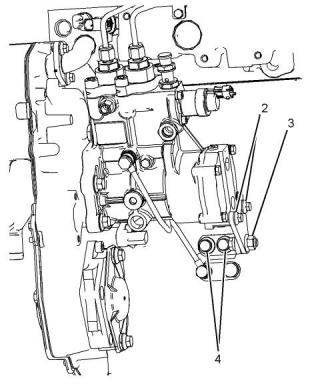

(2) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

(3) Tighten the fasteners to the following torque.

............................................................44 N·m (32 lb ft)

(4) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

Note: The fasteners (2), (3), and (4) should be

tightened in the sequence that is shown in illustration

6

Illustration 5

g03543140

Typical example

Illustration 7

g03543096

Typical example

(5) Tighten the bolts to the following torque......10 N·m

(89 lb in)

i05295515

Fuel Injectors

Refer to Operation and Maintenance Manual,

“General Hazard Information and High Pressure Fuel

Lines” before adjustments and repairs are performed.

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

Illustration 6

g03543138

Typical example

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

8

UENR4460

Specifications Section

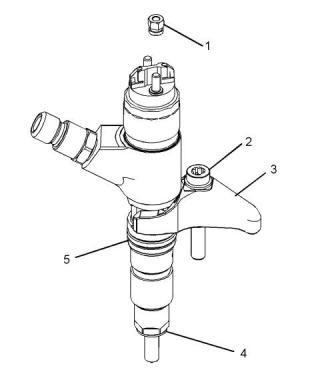

Illustration 8

g03344528

Illustration 9

g03590389

Typical example

Typical example

(3) Clamp

(4) Washer

(5) O ring seal

(1) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

(1) Torque for the nuts..........................2 N·m (18 lb in)

(2) Tighten the bolt to the following torque. ......21 N·m

(15 lb ft)

(2) Torque for the bolt in the clamp for the fuel

injection nozzle...................................27 N·m (20 lb ft)

(3) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

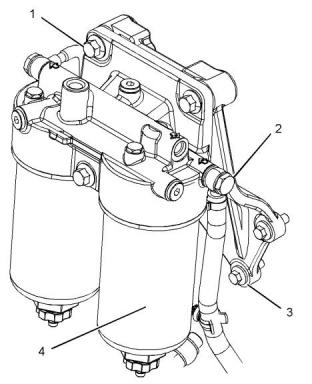

i05547012

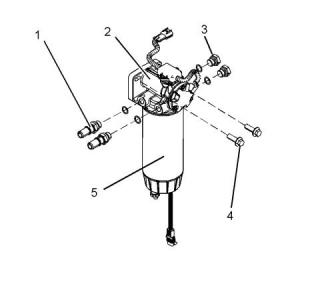

Fuel Filter Base

(Twin Secondary Fuel Filter

Base)

i05258818

Fuel Priming Pump

(Mechanical Priming Pump)

NOTICE

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

If necessary, install a new fuel filter element to

canister (5). Refer to Operation and Maintenance

Manual, “Fuel System Primary Filter (Water

Separator) Element - Replace” for the correct

procedure.

If necessary, install a new fuel filter to canister (4).

Refer to Operation and Maintenance Manual, “Fuel

System Secondary Filter - Replace” for the correct

procedure.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

9

Specifications Section

If necessary, install a new fuel filter element to

canister (5). Refer to Operation and Maintenance

Manual, “Fuel System Primary Filter (Water

Separator) Element - Replace” for the correct

procedure.

Illustration 11

g03348301

Typical example

(2) Primary fuel filter base

Illustration 10

g03347830

Typical example

(2) Primary fuel filter base

(1) Tighten the connectors to the following torque.

............................................................20 N·m (15 lb ft)

(1) Tighten the connectors to the following torque.

............................................................20 N·m (15 lb ft)

(3) Tighten the plugs to the following torque.

............................................................20 N·m (15 lb ft)

(3) Tighten the plugs to the following torque.

............................................................20 N·m (15 lb ft)

(4) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

(4) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

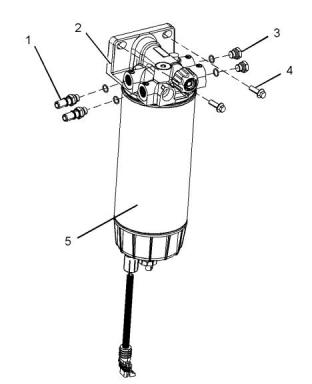

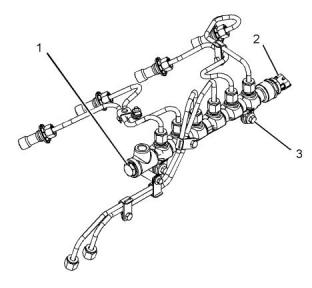

i05536738

Fuel Manifold (Rail)

i05259696

Fuel Priming Pump

(Electric Fuel Priming Pump)

Refer to Operation and Maintenance Manual,

“General Hazard Information and High Pressure Fuel

Lines” before adjustments and repairs are performed.

NOTICE

NOTICE

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

Refer to Systems Operation, Testing and Adjust-

ing, “Cleanliness of Fuel System Components”

for detailed information on the standards of clean-

liness that must be observed during ALL work on

the fuel system.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

10

UENR4460

Specifications Section

Illustration 12

g03506648

Illustration 13

g01344742

Typical example

(A) Diameter of the lifter body....18.987 to 19.012 mm

(0.7475 to 0.7485 inch)

(1) Tighten the fuel pressure relief valve to the

following torque.................................100N·m (74 lb ft)

Bore diameter in the cylinder block

(2) Tighten the fuel pressure sensor to the following

torque..................................................70 N·m (52 lb ft)

...............19.05 to 19.082 mm (0.7500 to 0.7513 inch)

Clearance

(3) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

Clearance of the lifter..............0.038 to 0.095 mm

(0.0015 to 0.0037 inch)

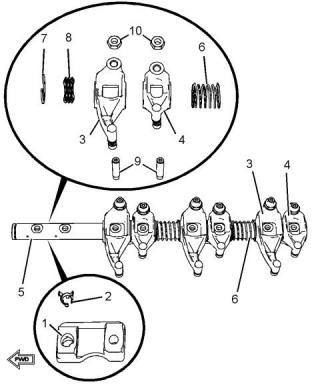

i02676273

i05535190

Lifter Group

Rocker Shaft

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

11

Specifications Section

(9) Adjuster

(10) Locknut

Torque for the locknut...................27 N·m (20 lb ft)

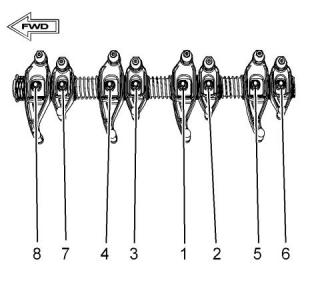

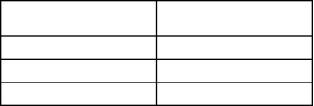

Illustration 15

g03506066

Tightening sequence

Illustration 14

g01455342

Typical example

Tighten the fasteners in the sequence that is in

illustration 15 . Tighten the fasteners to the following

torque..................................................35 N·m (25 lb ft)

(1) Pedestal

(2) Locator

(3) Inlet rocker arm

Diameter of the rocker arm bore

............................................25.013 to 25.051 mm

(0.98476 to 0.98626 inch)

(4) Exhaust rocker arm

Diameter of the rocker arm bore

............................................25.013 to 25.051 mm

(0.98476 to 0.98626 inch)

Clearance

Maximum clearance of both the rocker arm bores

........................................0.089 mm (0.0035 inch)

The service limit for both rocker arm bores

..........................................0.17 mm (0.0067 inch)

(5) Rocker shaft

Diameter of the rocker shaft

......24.962 to 24.987 mm (0.9828 to 0.9837 inch)

(6) Spring

(7) Snap ring

(8) Spring

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

12

UENR4460

Specifications Section

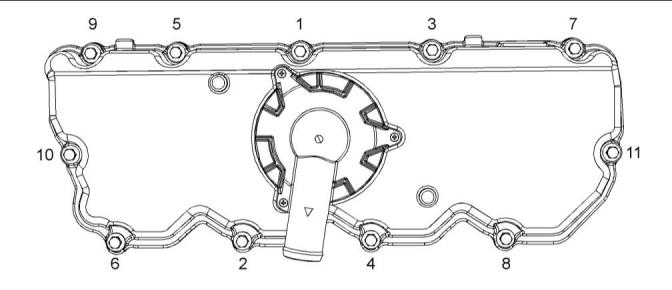

i05535194

Valve Mechanism Cover

Illustration 16

g03506070

Typical example

Tighten the bolts for the valve mechanism cover in

the sequence that is shown in illustration 16 to the

following torque...................................22 N·m (16 lb ft)

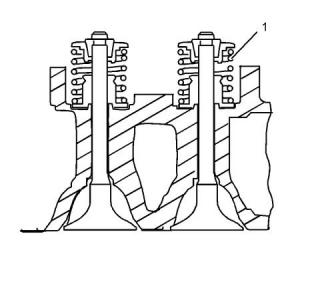

i02657602

Cylinder Head Valves

Illustration 17

g01335203

Typical example

The valve spring (1) may be used on the inlet valve or

the exhaust valve. When the valve springs are

replaced the valve springs must be replaced in pairs.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

UENR4460

13

Specifications Section

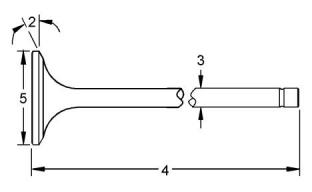

Table 1

i02934444

The load for the valve spring

The length of the valve spring

31.5 mm (1.2402 inch)

Cylinder Head

161.5 to 178.5 N

(36.3 to 40.1 lb)

337.9 ± 373.5 N (76 ± 84 lb)

21.5 mm (0.8465 inch)

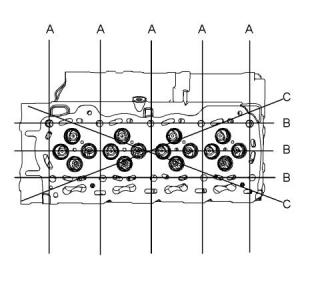

Illustration 19

g01250785

Illustration 18

g01335204

Typical example

(2) Valve face angle

Lubricate the threads and the underside of the head

bolts with clean engine oil.

Inlet .....................................................30 degrees

Exhaust ..............................................45 degrees

Tighten the bolts in the sequence that is shown in

illustration 19 to the following torque.........50 N·m

(37 lb ft)

(3) Valve stem diameter

Inlet....5.942 to 5.957 mm (0.2339 to 0.2345 inch)

Exhaust...................................5.927 to 5.942 mm

(0.2333 to 0.2339 inch)

Tighten the bolts again to the following torque.

...................................................100N·m (74 lb ft)

Tighten the head bolts to the additional amount.

..........................................................225 degrees

Clearance

Minimum thickness of cylinder head .........100.95 mm

(3.9744 inch)

Maximum clearance of the inlet valve stem

..........................................0.05 mm (0.0020 inch)

The service limit for the inlet valve stem

..........................................0.08 mm (0.0031 inch)

Clearance

Maximum clearance of the exhaust valve stem

........................................0.065 mm (0.0026 inch)

The service limit for the inlet valve stem

..........................................0.09 mm (0.0035 inch)

(4) Length of valve

Inlet valve........................107.925 to 108.375 mm

(4.2490 to 4.2667 inch)

Exhaust valve..................107.703 to 108.153 mm

(4.2403 to 4.2580 inch)

(5) Valve head

Diameter of inlet valve head ......................35 mm

(1.3780 inch)

Diameter of exhaust valve head ................33 mm

(1.2992 inch)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

14

UENR4460

Specifications Section

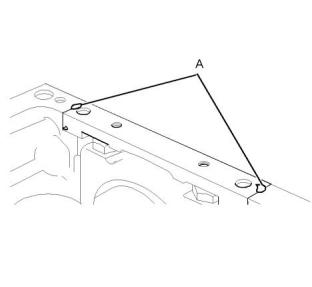

Illustration 20

g01455374

Note: The maximum distortion of the bottom face of

the cylinder head is given in table 2 .

Table 2

Maximum Permissible

Dimension

Distortion

Illustration 21

g01335214

Typical example

Width (A)

Length (B)

0.03 mm (0.0018 inch)

0.05 mm (0.0019 inch)

0.05 mm (0.0019 inch)

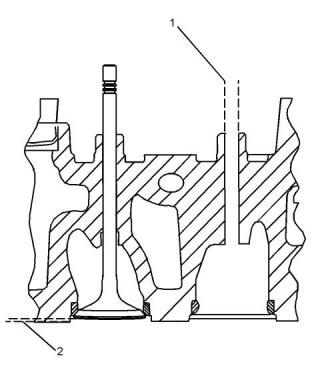

(1) Valve guide bores

Diagonal Line (C)

Inlet and exhaust..................... 5.979 to 5.992 mm

(0.2354 to 0.2359 inch)

(2) Valve depths

Inlet....0.905 to 1.163 mm (0.0356 to 0.0458 inch)

The service limit for the depth of the inlet valve

.......................................... 1.41 mm (0.0555 inch)

Exhaust...................................0.876 to 1.131 mm

(0.0345 to 0.0445 inch)

The service limit for the exhaust valve depth

.......................................... 1.38 mm (0.0543 inch)

i05775908

Turbocharger

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

15

Specifications Section

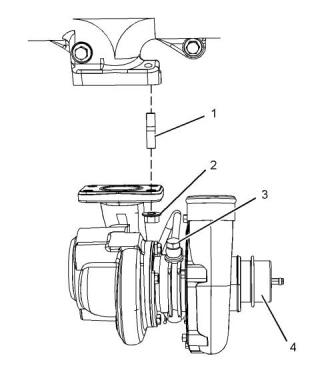

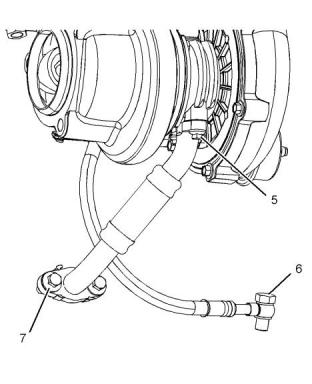

Illustration 22

g03544117

Illustration 23

g03544119

Typical example

Typical example

(1) Tighten the studs to the following torque.

............................................................18 N·m (13 lb ft)

(5) Tighten the bolt to the following torque. ........9 N·m

(80 lb in)

(2) Tighten the nuts to the following torque. .....44 N·m

(32 lb ft)

(6) Tighten the bolt to the following torque. ......18 N·m

(13 lb ft)

(3) Tighten the bolt to the following torque. ......18 N·m

(13 lb ft)

(7) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

(4) Actuator

i02873699

The maximum test pressure for the wastegate

..................................................112 kPa (16.2445 psi)

Exhaust Manifold

The movement for the rod actuator .................... 1 mm

(0.0394 inch)

Table 3

The pressure for the

Engine kW

wastegate

106 - 90

90 - 74.5

74.5 - 55

170 kPa (25 psi)

151 kPa (22 psi)

136 kPa (20 psi)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

16

UENR4460

Specifications Section

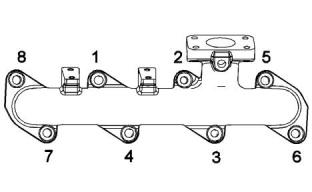

Illustration 24

g01430662

Illustration 26

g01195129

Typical example

Typical example

Tighten the exhaust manifold bolts in the sequence

that is shown in illustration 24 to the following torque.

............................................................40 N·m (30 lb ft)

(2) Bolt

Tighten the bolt to the following torque......95 N·m

(70 lb ft)

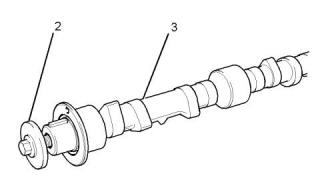

i02526614

(3) The diameters of the camshaft journals are given

in the following tables.

Camshaft

Table 4

Camshaft Journals

Standard Diameter

50.711 to 50.737 mm

(1.9965 to 1.9975 inch)

1

50.457 to 50.483 mm

(1.9865 to 1.9875 inch)

2

3

49.949 to 49.975 mm

(1.9665 to 1.9675 inch)

Maximum wear on the camshaft journals...... 0.05 mm

(0.0021 inch)

Check the camshaft lobes for visible damage. If a

new camshaft is installed you must install new lifters.

i02658683

Camshaft Bearings

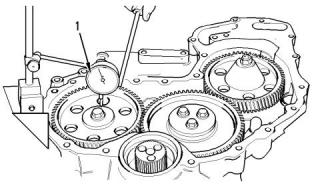

Illustration 25

g00987750

Checking the end play of the camshaft

(1) End play of a camshaft.............0.126 to 0.558 mm

(0.0050 to 0.0220 inch)

Maximum permissible end play of a worn camshaft

.................................................0.62 mm (0.0244 inch)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

17

Specifications Section

Illustration 27

g01335770

Illustration 28

g01455385

Typical example

Typical example

(1) The diameter of the installed camshaft bearing

.............50.787 to 50.848 mm (1.9995 to 2.0019 inch)

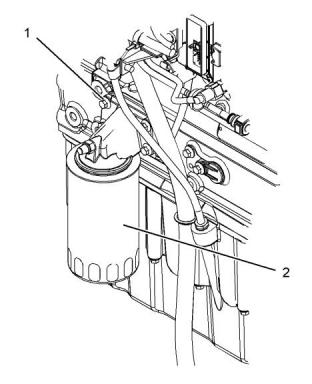

(1) Setscrew

Tighten the setscrews to the following torque.

........................................................22 N·m (16 ft)

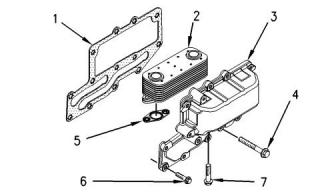

i02934454

Engine Oil Filter Base

(2) Engine oil filter

Tighten the engine oil filter to the following torque.

.......................................................12 N·m (8 lb ft)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

18

UENR4460

Specifications Section

Illustration 30

g00952614

Typical example

(1) Joint

(2) Oil cooler

(3) Housing

(4) Setscrew

(5) Seal

(6) Setscrew

(7) Setscrew

Illustration 29

g01455386

Typical example

(3) Setscrew

Tighten the setscrews to the following torque.

........................................................22 N·m (16 ft)

(4) Engine oil filter

Tighten the engine oil filter to the following torque.

.......................................................12 N·m (8 lb ft)

(5) Plug

Tighten the plug to the following torque.....12 N·m

(8 lb ft)

Illustration 31

g01335773

i02658685

Setscrews

Engine Oil Cooler

Tighten the setscrews (7) to the following torque.

.....................................................22 N·m (16 lb ft)

Setscrews

Tighten the setscrews (4) and (6) in the sequence

that is in illustration 31 to the following torque.

.....................................................22 N·m (16 lb ft)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

19

Specifications Section

i05663178

Engine Oil Pump

Engines with Balancer Group

Type ...............................Gear-driven differential rotor

Number of lobes

Inner rotor ........................................................... 6

Outer rotor ..........................................................7

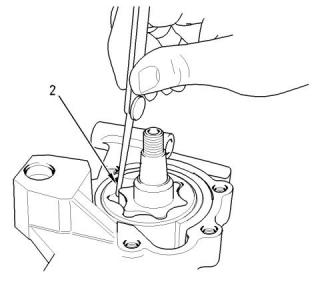

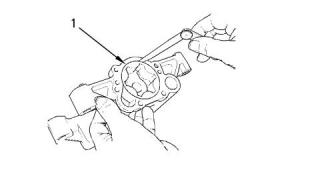

Illustration 33

g00989236

Inner rotor

(2) Clearance of inner rotor to outer rotor

.................0.050 to 0.200 mm (0.0020 to 0.0079 inch)

Illustration 32

g00989248

The oil pump for the balancer

(1) Clearance of the outer rotor to the body

...................0.130 to 0.24 mm (0.0050 to 0.0094 inch)

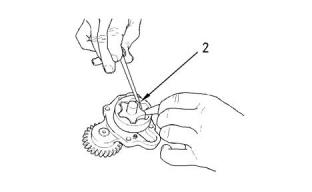

Illustration 34

g00989217

The end play for the rotor

(3) End play of rotor assembly

Inner rotor.....................................0.04 to 0.11 mm

(0.0016 to 0.0043 inch)

Outer rotor...................................0.04 to 0.00 mm

(0.0016 to 0.0043 inch)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

20

UENR4460

Specifications Section

Inner rotor ...........................................................5

Outer rotor ..........................................................6

Illustration 35

g01455406

The end cover

Illustration 37

g00938064

(4) Torque for cover bolts for oil pump..............26 N·m

(19 lb ft)

The oil pump

(1) Clearance of the outer rotor to the body

.............0.205 to 0.315 mm (0.00807 to 0.01240 inch)

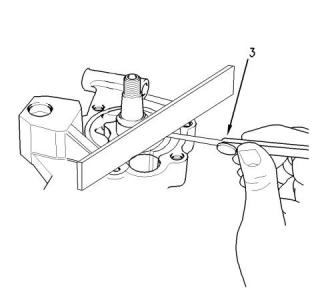

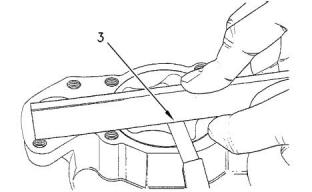

Illustration 36

g01335780

Idler gear and pump gear

Illustration 38

g00938061

Note: Replace the idler gear bolt (5) and the nut for

the oil pump gear (6).

Checking the clearance

(2) Clearance of inner rotor to outer rotor

.................0.040 to 0.127 mm (0.0015 to 0.0050 inch)

(5) Tighten the idler gear bolt to the following torque.

............................................................26 N·m (19 lb ft)

Note: Set the engine to the TC position. Refer to

Systems Operation, Testing and Adjusting Manual,

“Finding Top Center Position for No. 1 Piston”. Install

the balancer. Refer to Disassembly and Assembly,

“Balancer - Install”. Install the gear for the oil pump

and tighten the nut (6).

(6) Tighten the nut to the following torque........95 N·m

(70 lb ft)

Tighten the bolts that hold the balancer to the cylinder

block to the following torque...............54 N·m (40 lb ft)

Engines without Balancer Group

Type ...............................Gear-driven differential rotor

Number of lobes

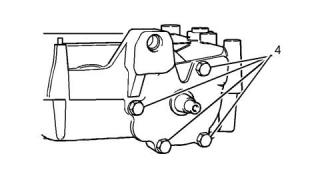

Illustration 39

g00938799

Checking the end play

(3) End play of rotor assembly

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

21

Specifications Section

Inner rotor................................0.038 to 0.089 mm

(0.0014 to 0.0035 inch)

Outer rotor...................................0.04 to 0.09 mm

(0.00157 to 0.00354 inch)

Tighten the bolts that hold the front cover of the oil

pump assembly to the following torque............26 N·m

(19 lb ft)

i01958104

Engine Oil Pressure

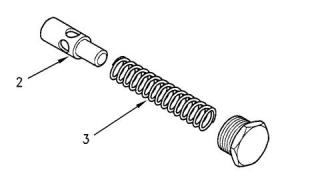

Illustration 41

g00921377

Relief valve and spring

The minimum oil pressure at the maximum engine

speed and at normal operating temperature is the

following value...................................300 kPa (43 psi)

(1) Tighten the plug for the relief valve to the following

torque..................................................35 N·m (26 lb ft)

(2) Plunger

i05663157

Diameter of the plunger.......19.139 to 19.225 mm

(0.75350 to 0.75689 inch)

Engine Oil Bypass Valve

Clearance of plunger in bore....... 0.06 to 0.09 mm

(0.00236 to 0.00354 inch)

(3) Spring

Installed in the Oil Pump

Length of the spring ........80.94 mm (3.1866 inch)

Installed in the Balancer

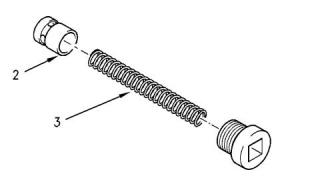

Illustration 40

g00919893

Typical engine oil pump

Illustration 42

g00919890

Plug

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

22

UENR4460

Specifications Section

Front sealant

Illustration 43

g00921379

The relief valve for the balancer

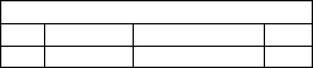

(1) Tighten the plug for the relief valve to the following

torque..................................................35 N·m (26 lb ft)

(2) Plunger

Diameter of the plunger...........14.46 to 14.48 mm

(0.5692 to 0.5700 inch)

Illustration 44

g01254690

Applying sealant

Clearance of the plunger in the bore

..............0.04 to 0.08 mm (0.0015 to 0.0031 inch)

Apply Tooling (A) to the cylinder block and to the

timing case.

(3) Spring

Note: Apply a sealant bead of 3.5 mm (0.1378 inch)

that is shown in illustration 44 .

Length of the spring .............67 mm (2.6378 inch)

Rear sealant

i04315734

Note: Install the rear oil seal before sealant is applied

Engine Oil Pan

to the bridge.

Table 5

Required Tools

Tool

Part Number

Part Description

Loctite 5900

Qty

A

-

1

Illustration 45

g01254887

Applyin, g sealant

ApplyTooling (A) to the bridge. The sealant must not

protrude more than 5 mm (0.1969 inch) above the

bridge.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

23

Specifications Section

Unfiltered Breather

Illustration 46

g01255016

Typical example

Illustration 47

g03506659

Typical example

(1) Tighten the four front bolts in position (X) to the

following torque...................................22 N·m (16 lb ft)

Align the outlet of the breather to the flexible pipe.

(1) Clamp

Tighten the remaining bolts to the following torque.

............................................................22 N·m (16 lb ft)

Tighten the clamp to the following torque.

......................................................5 N·m (44 lb in)

(2) Drain plug

Tighten the drain plug for the engine oil pan to the

following torque............................34 N·m (25 lb ft)

(2) Tighten the setscrew to the following torque.

............................................................22 N·m (16 lb ft)

i05536751

Crankcase Breather

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

24

UENR4460

Specifications Section

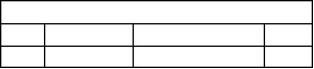

Filtered Breather

Table 6

Required Tools

Part Description

Loctite 575

Tool

Part Number

Qty

A

-

1

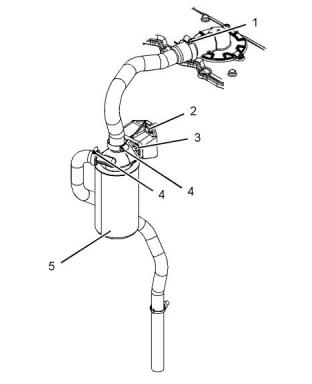

Illustration 49

g01253716

Illustration 48

g03506661

Typical example

Typical example

Note: Apply Tooling (A) to the O-ring (4) in order to

install the water temperature regulator housing (2).

(1) Clamps

(1) Tighten the bolts that fasten the housing to the

following torque...................................44 N·m (32 lb ft)

Tighten the clamps to the following torque.

......................................................5 N·m (44 lb in)

(2) Water temperature regulator housing

(3) Water temperature regulator

(2) (3) Setscrews

Tighten the setscrews to the following torque.

.....................................................22 N·m (16 lb ft)

Opening temperature..........................82° to 87°C

(179.6000° to 156.6000°F)

Full opening temperature...... 95 °C (203.0000 °F)

Minimum stroke at full temperature..............9 mm

(0.3543 inch)

(4) Tighten the clamps to the following torque.

.............................................................3 N·m (27 lb in)

(5) Canister

Tighten the canister to the following torque.

..................................................12 N·m (106 lb in)

i02363605

Water Pump

i05775915

Water Temperature Regulator

and Housing

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

25

Specifications Section

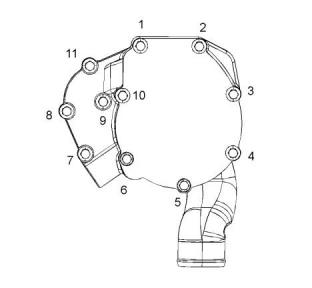

Illustration 50

g01183807

Tightening sequence

Tighten the setscrews in the numerical sequence that

is shown in illustration 50 to the following torque.

............................................................22 N·m (16 lb ft)

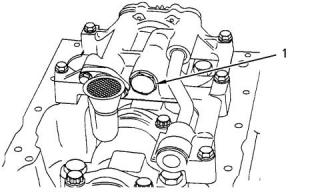

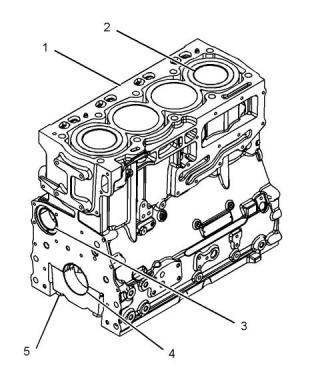

Illustration 51

g01335800

Cylinder block

i04135329

Cylinder Block

(1) Cylinder block

(2) Cylinder bore....................105.000 to 105.025 mm

(4.1338 to 4.1348 inch)

The maximum permissible wear for the cylinder bore

.................................................0.15 mm (0.0059 inch)

(3) Camshaft bearings

Diameter of the bushing in the cylinder block for

the number 1 camshaft bearing

......55.563 to 55.593 mm (2.1875 to 2.1887 inch)

Diameter of the bore in the cylinder block for the

number 2 camshaft journal

......50.546 to 50.597 mm (1.9900 to 1.9920 inch)

Diameter of the bore in the cylinder block for the

number 3 camshaft journal

......50.038 to 50.089 mm (1.9700 to 1.9720 inch)

(4) Main bearings

Bore in the cylinder block for the main bearings

......80.416 to 80.442 mm (3.1660 to 3.1670 inch)

Install the main bearing cap bolts (5). Refer to

Disassembly and Assembly, “Crankshaft Main

Bearings - Remove and Install” or Disassembly and

Assembly, “Crankshaft - Install” for the correct

procedure.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

26

UENR4460

Specifications Section

(5) Main bearing cap bolts

Note: The timing mark is toward the outside of the

crankshaft when the gear is installed on the

crankshaft.

Evenly tighten the main bearing cap bolts. Torque

for the main bearing cap bolts..................245 N·m

(180 lb ft)

(5) Crankshaft end play

Note: Ensure that the crankshaft can rotate freely.

The end play of a new crankshaft

.................. 0.05 to 0.38 mm (0.002 to 0.015 inch)

Maximum crankshaft end play................ 0.51 mm

(0.020 inch)

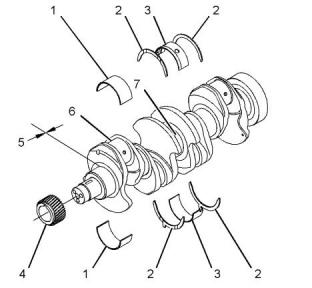

i05568790

Crankshaft

(Spheroidal Graphite Iron (SGI)

Crankshaft)

(6) Connecting rod journal. Refer to Specifications,

“Connecting Rod Bearing Journal” for more

information on the connecting rod bearing journals.

(7) Main bearing journal. Refer to Specifications,

“Main Bearing Journal” for information on the main

bearing journals.

i02934550

Crankshaft Seals

Illustration 52

g03435603

Typical Example

(1) Connecting rod bearings. Refer to Specifications,

“Connecting Rod Bearing Journal” for more

information on the connecting rod bearing journals

and connecting rod bearings.

Illustration 53

g01455434

(2) Thrust washers

Typical example

Standard thickness ..................... 2.26 to 2.31 mm

(0.089 to 0.091 inch)

(1) Crankshaft

Oversize thickness...................... 2.45 to 2.50 mm

(0.097 to 0.098 inch)

(2) Crankshaft seal

(3) Plastic sleeve

(4) Alignment tool

(3) Main bearings. Refer to Specifications, “Main

Bearing Journal” for information on the main bearing

journals and for information on the main bearings.

(4) Maximum permissible temperature of the gear for

installation on the crankshaft..............180 °C (356 °F)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

27

Specifications Section

The Shell for the Connecting Rod

Bearings

Standard Bearing Shells

Thickness at center of the shells ... 1.995 to 2.002 mm

(0.0785 to 0.0788 inch)

Width of the connecting rod bearing shells

.................31.47 to 31.73 mm (1.2390 to 1.2492 inch)

Clearance between the bearing shell and the

connecting rod bearing journals .... 0.031 to 0.078 mm

(0.0012 to 0.0031 inch)

i05569069

Main Bearing Journal

(Spheroidal Graphite Iron (SGI)

Crankshaft)

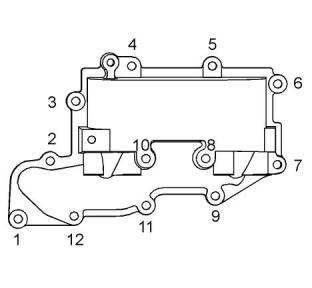

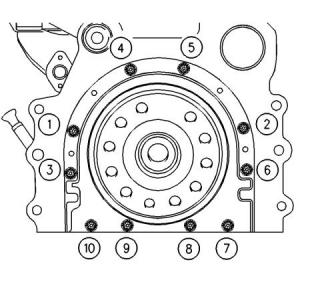

Illustration 54

g00915076

(5) Tighten bolts 1, 2, 3, 4, 5, 6, 7, and 10 in the

sequence that is shown in Illustration 54 to the

following torque...................................22 N·m (16 lb ft)

The original size of the main bearing journal

.............76.159 to 76.180 mm (2.9984 to 2.9992 inch)

Remove the alignment tool.

Tighten bolts 8 and 9 in the sequence that is shown in

Illustration 54 to the following torque...............22 N·m

(16 lb ft)

Maximum permissible wear of the main bearing

journals..................................0.040 mm (0.0016 inch)

Surface finish of bearing journals, crank pins, and

radii..............................Ra 0.0025 microns (10 µ inch)

i05568830

Connecting Rod Bearing

Journal

(Spheroidal Graphite Iron

Crankshaft)

The Shell for the Main Bearings

Standard Bearing Shells

Thickness at center of the shells ... 2.083 to 2.089 mm

(0.0820 to 0.0823 inch)

Width of the main bearing shells ... 31.62 to 31.88 mm

(1.244 to 1.255 inch)

The original size of the connecting rod bearing journal

...............................................67.99 mm (2.6768 inch)

Clearance between the bearing shell and the main

bearing journals..............................0.057 to 0.117 mm

(0.0022 to 0.0046 inch)

Maximum permissible wear of a bearing journal on a

new connecting rod .................0.04 mm (0.0016 inch)

i05569109

Width of the connecting rod bearing journals

.............40.348 to 40.424 mm (1.5885 to 1.5915 inch)

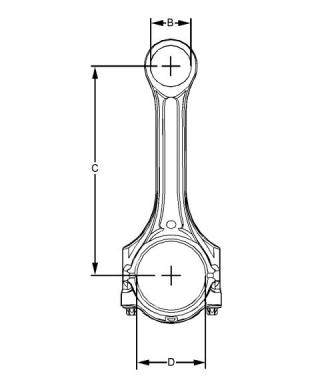

Connecting Rod

(For Use With Spheroidal

Graphite Iron (SGI) Crankshaft)

Surface finish of connecting rod bearing journals and

radii..............................Ra 0.0025 microns (10 µ inch)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

28

UENR4460

Specifications Section

Table 7

Bearing Width for the Con- 31.47 mm (1.2390 inch) to

necting Rod

31.73 mm (1.2492 inch)

Bearing Width for the Con- 31.47 mm (1.2390 inch) to

necting Rod Cap

31.73 mm (1.2492 inch)

Thickness of Connecting 1.995 mm (0.0785 inch) to

Rod Bearing at the Center 2.002 mm (0.0788 inch)

Thickness of Connecting 1.995 mm (0.0785 inch) to

Rod Bearing for the Cap at 2.002 mm (0.0788 inch)

the Center

Bearing Clearance

0.031 mm (0.0012 inch) to

0.078 mm (0.0031 inch)

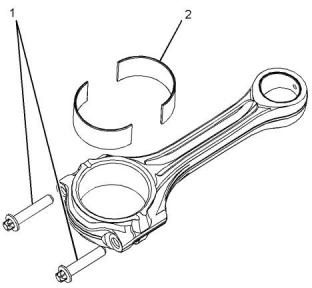

Illustration 55

g03442137

Typical example

Illustration 56

g01356356

Alignment of the bearing shell

The mating surfaces of the connecting rod are

produced by hydraulically fracturing the forged

connecting rod.

Illustration 57

g03442182

Typical example

(1) Tighten the setscrews for the connecting rod to

the following torque.............................40 N·m (30 lb ft)

(B) Diameter of the bore for the piston pin

.....................43.01 to 43.04 mm (1.693 to 1.694 inch)

Tighten the setscrews for the connecting rod for an

additional 120 degrees. The setscrews for the

connecting rod (1) must be replaced after this

procedure.

(C) Distance between bearing centers

.................219.05 to 219.10 mm (8.624 to 8.626 inch)

(D) Diameter for the bore for the connecting rod

bearing.......................................72.045 to 72.058 mm

(2.8364 to 2.8369 inch)

Note: Always tighten the connecting rod cap to the

connecting rod, when the assembly is out of the

engine. Tighten the assembly to the following torque

15 N·m (133 lb in).

(A) The bearing shell for the connecting rod must be

aligned equally from both ends of the connecting rod.

(2) The bearing shell for the connecting rod

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

29

Specifications Section

Illustration 58

g01356360

Illustration 59

g01155119

Typical example

Typical example

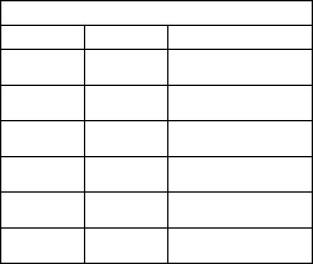

Connecting rods are color coded. The color code is a

reference for the length (Y) of the connecting rod.

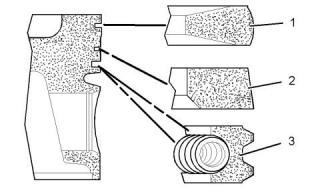

(1) Top compression ring

Refer to table 7 for the different lengths of connecting

rods.

The shape of the top compression ring ....tapered

Table 8

Ring gap......................................0.30 to 0.45 mm

(0.0118 to 0.0177 inch)

Length Grades for Connecting Rods

Length (Y)

Note: When you install a new top compression ring,

make sure that the word “TOP” is facing the top of

the piston. New top piston rings have a yellow

identification mark which must be on the left of the

ring end gap when the top piston ring is installed on

an upright piston.

Grade Letter Color Code

163.310 mm (6.4295 inch) to

163.343 mm (6.4308 inch)

R

O

W

G

P

Red

163.264 mm (6.4277 inch) to

163.297 mm (6.4290 inch)

Orange

163.219 mm (6.4259 inch) to

163.252 mm (6.4272 inch)

(2) Intermediate compression ring

White

Green

Purple

The shape of the intermediate compression ring

...............Internal bevel in the bottom edge with a

tapered face

163.173 mm (6.4241 inch) to

163.206 mm (6.4254 inch)

163.127 mm (6.4223 inch) to

163.160 mm (6.4236 inch)

Width of intermediate compression ring

163.081 mm (6.4205 inch) to

163.114 mm (6.4218 inch)

............2.47 to 2.495 mm (0.0972 to 0.0982 inch)

B

Blue

The clearance between a new intermediate

compression ring and the piston groove in a new

piston............................................0.07 to 0.11 mm

(0.00276 to 0.00433 inch)

i05663413

Piston and Rings

Ring gap......................................0.65 to 0.85 mm

(0.0256 to 0.0335 inch)

Note: When you install a new intermediate

compression ring, make sure that the word “TOP” is

facing the top of the piston. New intermediate rings

have a blue identification mark which must be on the

left of the ring end gap when the top piston ring is

installed on an upright piston.

(3) The oil control ring

Width of oil control ring................2.97 to 2.99 mm

(0.1169 to 0.1177 inch)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

30

UENR4460

Specifications Section

The clearance between a new oil control ring and

the groove in a new piston..........0.03 to 0.07 mm

(0.0011 to 0.0027 inch)

Ring gap......................................0.25 to 0.45 mm

(0.00984 to 0.01772 inch)

The valve must move freely. Tighten the bolt to the

following torque.......................................9 N·m (7 lb ft)

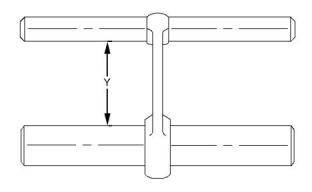

Piston Cooling Jet Alignment

Note: The oil control ring is a two-piece ring that is

spring loaded. A pin is used in order to hold both ends

of the spring of the oil control ring in position. The

ends of the spring of the oil control ring must be

installed opposite the end gap of the oil control ring.

Note: Ensure that the ring end gaps of the piston

rings are spaced 120 degrees from each other.

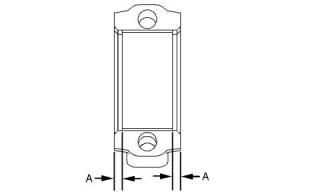

Piston

Note: An arrow which is marked on the piston crown

must be toward the front of the engine.

Piston height above cylinder block.... 0.40 to 0.54 mm

(0.0157 to 0.0213 inch)

Width of top groove in the piston ................... Tapered

Width of second groove in new piston

.....................2.56 to 2.58 mm (0.1008 to 0.1016 inch)

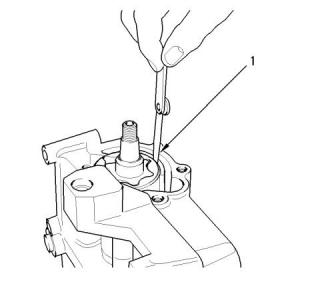

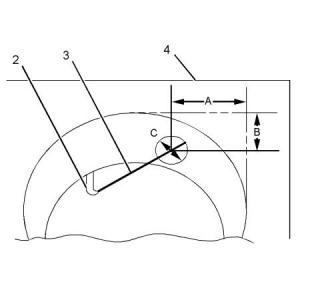

Illustration 61

g01352578

(2) Piston cooling jet

(3) Rod

(4) Cylinder block

Width of third groove in new piston.... 3.02 to 3.04 mm

(0.1189 to 0.1197 inch)

Piston pin

Use the following procedure in order to check the

alignment of the piston cooling jet.

Diameter of a new piston pin

......39.694 to 39.700 mm (1.5628 to 1.5630 inch)

1. Insert rod (3) into the end of the piston cooling jet

(2). Rod (3) has a diameter of 1.70 mm

(0.067 inch). Rod (3) must protrude out of the top

of the cylinder block.

i02696381

Piston Cooling Jet

2. Dimension (A) is 50.75 mm (1.9980 inch) and

dimension (B) is 9.35 mm (0.3681 inch).

Dimension (A) and dimension (B) are tangential to

the cylinder bore (4).

3. The position of the rod (3) must be within

dimension (C). Dimension (C) is 14 mm

(0.5512 inch).

Note: Ensure that the rod (3) can not damage the

piston cooling jet when the alignment is checked. The

piston cooling jets can not be adjusted. If a piston

cooling jet is not in alignment the piston cooling jet

must be replaced.

i05583730

Balancer

Illustration 60

g01352576

(1) Installed piston cooling jets

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

31

Specifications Section

Illustration 62

g00929516

Typical example

(1) Tighten the six mounting bolts to the following

torque..................................................54 N·m (40 lb ft)

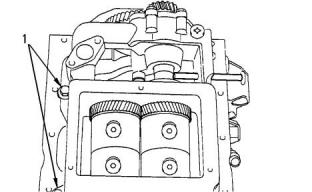

Illustration 64

g01332261

i02935111

Typical example

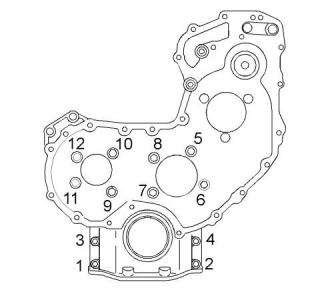

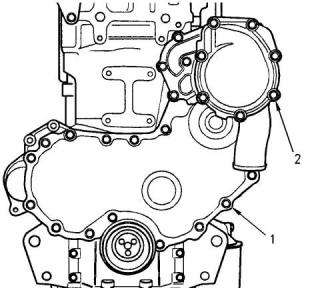

Front Housing and Covers

Tighten the setscrew to the sequence that is shown in

illustration 64 to the following torque. ..............28 N·m

(20 lb ft)

(1) Tighten the bolts that fasten the front cover to the

front housing to the following torque.................22 N·m

(16 lb ft)

The front housing must be aligned to the cylinder

block face..............................+ 0.05 to minus 0.05 mm

(+ 0.0020 to minus 0.0020 inch)

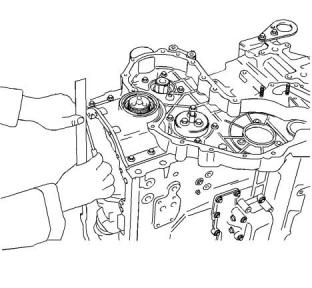

Illustration 65

g00918672

Illustration 63

g01332260

Typical example

Alignment

(2) Tighten the bolts that fasten the water pump to the

front housing to the following torque.................22 N·m

(16 lb ft)

Note: Refer to Specifications, “Water Pump” for the

correct bolt tightening sequence for the water pump.

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

32

UENR4460

Specifications Section

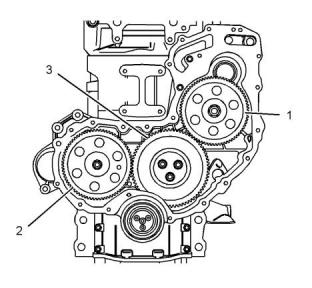

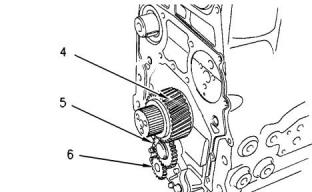

i05546629

Clearance of idler gear bearing on hub

............0.06 to 0.102 mm (0.0024 to 0.0040 inch)

Gear Group (Front)

Idler gear end play ....................0.10 to 0.205 mm

(0.0039 to 0.0081 inch)

Maximum permissible end play ..............0.38 mm

(0.015 inch)

Idler gear end play with roller bearings

............0.24 to 0.954 mm (0.0094 to 0.0376 inch)

Number of teeth ................................................ 73

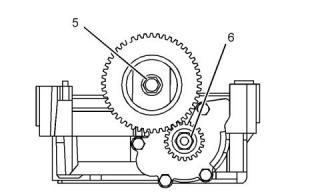

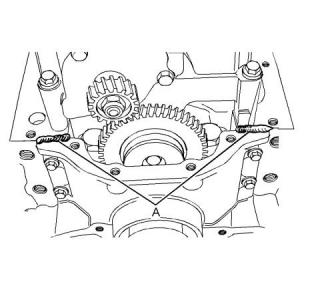

Illustration 67

g00996214

Illustration 66

g01335907

The gear train for the oil pump

Gear train

(4) Crankshaft gear

(1) Fuel injection pump drive gear

Bore diameter of crankshaft gear

..........51.00 to 51.03 mm (2.0079 to 2.0091 inch)

Tighten the nut to the following torque.....160 N·m

(118 lb ft)

Outside diameter of crankshaft hub

......51.021 to 51.002 mm (2.0087 to 2.0079 inch)

Number of teeth ................................................ 68

(2) Camshaft gear

Clearance of gear on crankshaft

....−0.021 to +0.028 mm (−0.0008 to 0.0011 inch)

Torque for the 8.8 graded bolt for the camshaft

gear..............................................95 N·m (70 lb ft)

Torque for the 10.9 graded bolt for the camshaft

gear............................................120 N·m (89 lb ft)

Number of teeth ................................................ 34

(5) Oil pump idler gear

Number of teeth ................................................ 68

(3) Idler gear and hub

Inside diameter of oil pump idler gear bearing

......16.012 to 16.038 mm (0.6304 to 0.6314 inch)

Outside diameter of oil pump idler gear shaft

......15.966 to 15.984 mm (0.6286 to 0.6293 inch)

Tighten the bolts for the idler gear to the following

torque...........................................44 N·m (33 lb ft)

Clearance of oil pump idler gear bearing on shaft

..........0.028 to 0.072 mm (0.0011 to 0.0028 inch)

Width of idler gear and split bearing assembly

......30.165 to 30.135 mm (1.1876 to 1.1864 inch)

End play of the oil pump idler gear

..........0.050 to 0.275 mm (0.0019 to 0.0108 inch)

Inside diameter of idler gear bearings with

flanges.................................50.797 to 50.818 mm

(1.9999 to 2.0007 inch)

(6) Oil pump gear

Outside diameter of idler gear hub

......50.716 to 50.737 mm (1.9967 to 1.9975 inch)

The number of teeth on the oil pump gear ....... 17

Backlash values

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

33

Specifications Section

Backlash between the idler gear (5) and the oil

Heat the flywheel ring gear to the following

pump drive gear (6) ....................0.05 to 0.14 mm

(0.0020 to 0.0055 inch)

temperature..................................250 °C (480 °F)

Note: Do not use an oxyacetylene torch to heat the

flywheel ring gear.

Backlash between the oil pump idler gear (5) and

the crankshaft gear (4) ................. 0.8 to 0.23 mm

(0.0315 to 0.0091 inch)

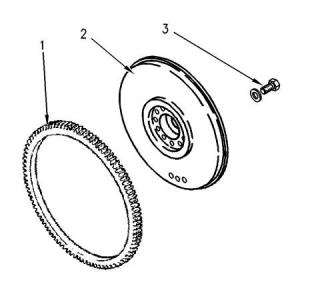

(2) Flywheel

(3) Bolt

Backlash between the idler gear (3) and the

crankshaft gear (4) ...................0.05 to 0.015 mm

(0.0020 to 0.0006 inch)

Tighten the flywheel bolts to the following torque.

................................................ 140 N·m (103 lb ft)

Backlash between the camshaft gear (2) and the

idler gear (3) ...............................0.05 to 0.15 mm

(0.0020 to 0.0059 inch)

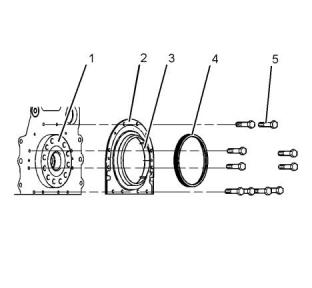

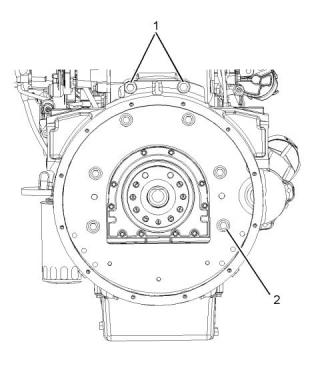

i04315754

Flywheel Housing

Backlash between the fuel injection pump gear

(1) and the idler gear (3) .............0.05 to 0.15 mm

(0.0020 to 0.0059 inch)

Table 9

Backlash between the water pump gear (not

shown) and the fuel injection pump gear (1)

..............0.05 to 0.15 mm (0.0020 to 0.0059 inch)

Backlash between the power take-off drive (if

equipped) and the idler gear (3)

Required Tools

Tool

Part Number

Part Description

Loctite 575

Qty

A

-

1

............0.05 to 0.250 mm (0.0020 to 0.0098 inch)

i04121789

Flywheel

Illustration 69

g01254486

Typical example

Illustration 68

g00584712

Typical example

Setscrew

(1)Tighten the setscrew to the following torque.

.....................................................75 N·m (55 lb ft)

(1) Flywheel ring gear

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

34

UENR4460

Specifications Section

Setscrew

Crankshaft Pulley for the Poly V-

Belt

(2)Tighten the setscrew to the following torque.

.....................................................63 N·m (46 lb ft)

Note: If 12.9 setscrews are installed, apply Tooling

(A) to the setscrews. Tighten the 12.9 setscrews to a

torque of 70 N·m (52 lb ft).

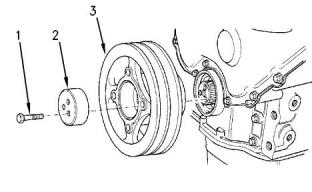

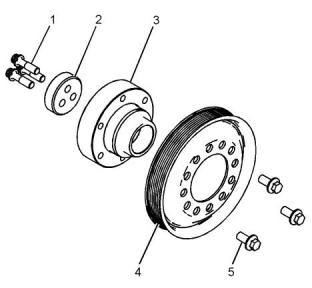

i02659096

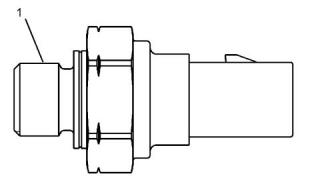

Crankshaft Pulley

Illustration 71

g01335910

Typical example

(1) Bolt

(2) Thrust block

(3) Crankshaft adapter

(4) Crankshaft pulley

(5) Bolt

Illustration 70

g00915497

(1) Tighten the three bolts for the thrust block to the

following torque.................................115 N·m (85 lb ft)

A standard pulley

Note: Lubricate the threads of the bolts with clean

engine oil before installation.

Note: Recheck the torque of the bolts (1) once.

(5) Tighten the three bolts for the crankshaft pulley to

the following torque.............................78 N·m (58 lb ft)

(1) Tighten the three bolts for the crankshaft pulley to

the following torque...........................115 N·m (85 lb ft)

Note: Recheck the torque of the bolts (1) once.

(2) Thrust block

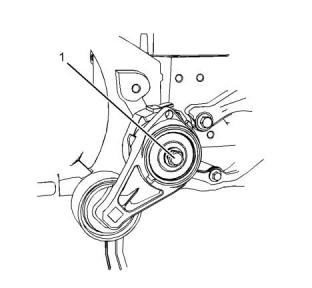

i04083729

Belt Tensioner

(3) Crankshaft pulley

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

35

Specifications Section

(1) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

(2) Tighten the bolts to the following torque......22 N·m

(16 lb ft)

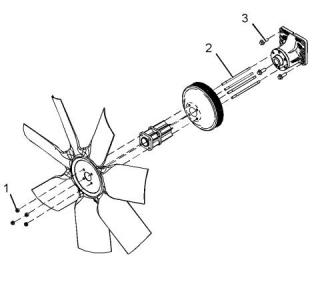

i04921370

Fan Drive

Illustration 72

g02291813

Typical example

(1) Tighten the bolt to the following torque. ......45 N·m

(33 lb ft)

Note: To install the belt tensioner, refer to

Disassembly and Assembly, “Belt Tensioner -

Remove and Install” for the correct procedure.

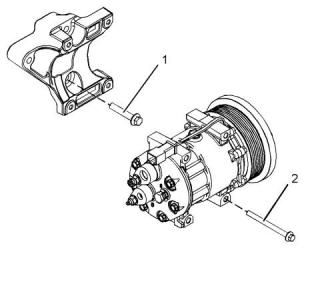

i03629003

Refrigerant Compressor

Illustration 74

g03087078

Typical example

(1) Tighten the locking nuts to the following torque.

............................................................22 N·m (16 lb ft)

(2) Tighten the studs (if equipped) to the following

torque.................................................11 N·m (97 lb in)

(3) Tighten the bolts to the following torque......44 N·m

(32 lb ft)

i01721280

Engine Lifting Bracket

All engines are equipped with two engine lifting

brackets.

Tighten the two bolts on each engine lifting

bracket to the following torque.....44 N·m (32 lb ft)

Illustration 73

g01946810

Typical example

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

36

UENR4460

Specifications Section

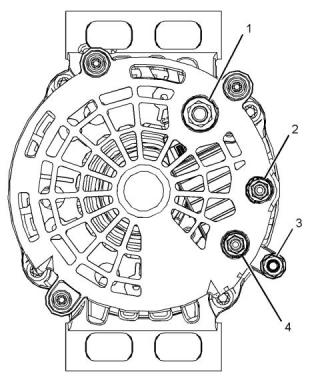

i05732072

Tighten the nut for the alternator pulley to the

following torque...................................95 N·m (70 lb ft)

Alternator

Output

The outputs of the alternators ..........80 Amp, 100

Amp, 120 Amp, or 150 Amp

The 12 V and 24 V Type 1

Alternators

Alternator Bracket

Illustration 76

g02151927

Typical example

(1) Tighten the setscrews that secure the alternator to

the bracket to the following torque......50 N·m (37 lb ft)

(2) Tighten the setscrews that secure the bracket to

the cylinder block to the following torque..........44 N·m

(32 lb ft)

Illustration 75

g02149533

Typical example

(1) Terminal “B+”

i05583725

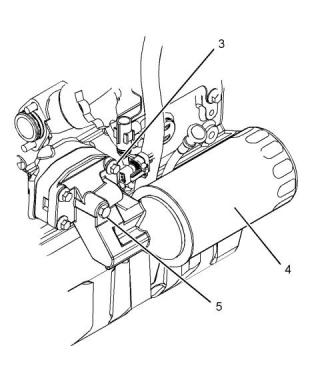

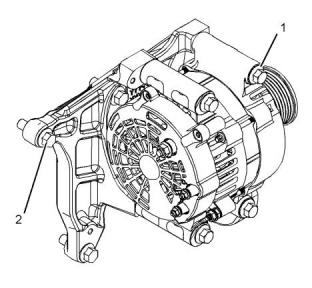

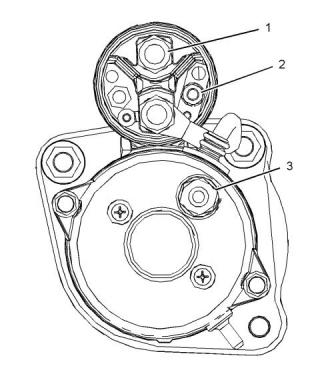

Starter Motor

Tighten the nut on the terminal to the following.

...................................................7.5 N·m (66 lb in)

(2) Terminal “D+”

Tighten the nut on the terminal to the following

torque.........................................2.2 N·m (19 lb in)

(3) Terminal “B-” (if equipped)

Tighten the nut on the terminal to the following

torque............................................7 N·m (62 lb in)

(4) Terminal “W”

Tighten the nut on the terminal to the following

torque.........................................2.2 N·m (19 lb in)

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

UENR4460

37

Specifications Section

12 V Starting Motor 3 kW, 4 kW, and

24 V Starting Motor 4.5 kW

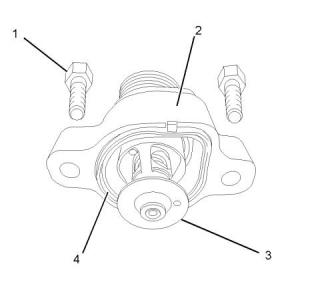

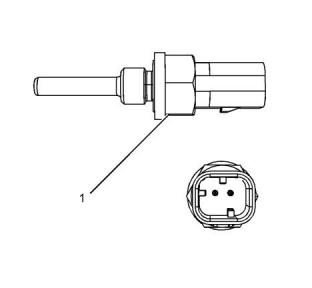

Illustration 78

g01502163

Typical example

(1) Tighten the temperature sensor to the following

torque..................................................20 N·m (15 lb ft)

Output type .....................................................Passive

Operating temperature ..........................−40 to 150 °C

(−40 to 302 °F)

i05535229

Engine Oil Pressure Sensor

Illustration 77

g01943502

Typical example

(1) Tighten the positive terminal nut to the following

torque..................................................15 N·m (11 lb ft)

(2) Tighten the solenoid terminal to the following

torque................................................5.8 N·m (51 lb in)

(3) Tighten the negative terminal nut to the following

torque..................................................18 N·m (13 lb ft)

Rated voltage .......................................................12 V

i05535225

Coolant Temperature Sensor

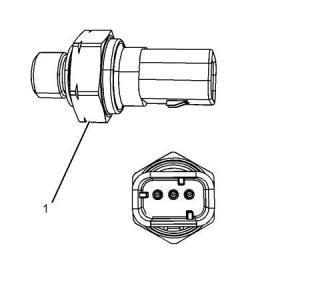

Illustration 79

g01502573

Typical example

(1) Tighten the oil pressure sensor to the following

torque.................................................10 N·m (90 lb in)

Operating temperature ..........................−40 to 125 °C

(−40 to 257 °F)

Operating voltage .................................5.0 ± 0.5 VDC

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

38

UENR4460

Specifications Section

i02652620

Boost Pressure Sensor

Illustration 81

g01332531

Typical example

(1) Sensor

Tighten the sensor to the following torque.

.....................................................20 N·m (15 lb ft)

Illustration 80

g01332534

Typical example

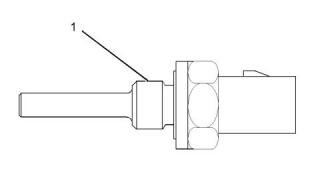

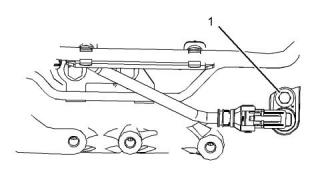

i05535345

Speed/Timing Sensor

(1) Sensor

Tighten the sensor to the following torque.

.......................................................10 N·m (7 lb ft)

i02652622

Inlet Manifold Temperature

Sensor

Illustration 82

g01854256

Typical example

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

UENR4460

39

Specifications Section

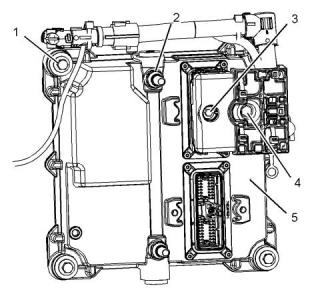

Illustration 83

g03506276

Illustration 84

g03506678

Typical example

Typical example

(5) Electronic control module (ECM)

(1) Tighten the bolt for the crankshaft position sensor

to the following torque.........................14 N·m (10 lb ft)

(1) Tighten the four bolts for the ECM to the following

torque..................................................22 N·m (16 lb ft)

(2) Tighten the setscrew for the sensor to the

following torque...................................14 N·m (10 lb ft)

(2) Tighten the connections (if equipped) to the

following torque...................................17 N·m (13 lb ft)

(3) Tighten the setscrew for the adaptor to the

following torque....................................6 N·m (53 lb in)

(3) Tighten the bolt to the following torque. ........5 N·m

(44 lb in)

i05536783

(4) Tighten the bolt to the following torque. .....6.5 N·m

(58 lb in)

Electronic Control Module

i02659261

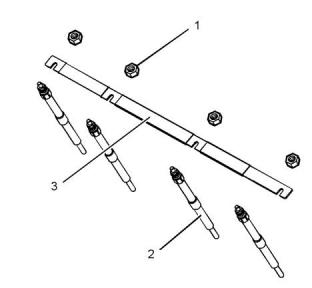

Glow Plugs

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

![]()

![]()

40

UENR4460

Specifications Section

Illustration 85

g01335949

Typical example

Tighten the glow plugs (2) in the cylinder head to the

following torque...................................15 N·m (11 lb ft)

Tighten the nuts (1) for the bus bar (3) that is installed

on top of the glow plugs to the following torque.

.............................................................2 N·m (18 lb in)

Voltage ...................................................12 or 24 volts

This document has been printed from SPI2. NOT FOR RESALE.

![]()

![]()

![]()

UENR4460

41

Index Section

Index

A

Engine Oil Pressure Sensor............................ 37

Engine Oil Pump.............................................. 19

Engines with Balancer Group ...................... 19

Engines without Balancer Group ................. 20

Exhaust Manifold............................................. 15

Alternator......................................................... 36

Alternator Bracket........................................ 36

The 12 Vand 24 V Type 1 Alternators......... 36

B

F

Balancer .......................................................... 30

Belt Tensioner.................................................. 34

Boost Pressure Sensor.................................... 38

Fan Drive......................................................... 35

Flywheel .......................................................... 33

Flywheel Housing............................................ 33

Front Housing and Covers............................... 31

Fuel Filter Base (Twin Secondary Fuel Filter

Base) ............................................................... 8

Fuel Injection Lines............................................ 4

Fuel Injection Pump........................................... 5

Fuel Injectors..................................................... 7

Fuel Manifold (Rail)............................................ 9

Fuel Priming Pump (Electric Fuel Priming

C

Camshaft......................................................... 16

Camshaft Bearings.......................................... 16

Connecting Rod (For Use With Spheroidal

Graphite Iron (SGI) Crankshaft)..................... 27

Connecting Rod Bearing Journal

(Spheroidal Graphite Iron Crankshaft)........... 27

The Shell for the Connecting Rod Bearings

................................................................... 27

Coolant Temperature Sensor........................... 37

Crankcase Breather......................................... 23

Filtered Breather.......................................... 24

Unfiltered Breather....................................... 23

Crankshaft (Spheroidal Graphite Iron (SGI)

Crankshaft).................................................... 26

Crankshaft Pulley ............................................ 34

Crankshaft Pulley for the Poly V-Belt........... 34

Crankshaft Seals ............................................. 26

Cylinder Block.................................................. 25

Cylinder Head.................................................. 13

Cylinder Head Valves ...................................... 12

Pump) .............................................................. 9

Fuel Priming Pump (Mechanical Priming

Pump) .............................................................. 8

G

Gear Group (Front).......................................... 32

Glow Plugs ...................................................... 39

I

Important Safety Information............................. 2

Inlet Manifold Temperature Sensor.................. 38

L

E

Lifter Group...................................................... 10

Electronic Control Module ............................... 39

Engine Design ................................................... 4

Engine Lifting Bracket...................................... 35

Engine Oil Bypass Valve ................................. 21

Installed in the Balancer............................... 21

Installed in the Oil Pump.............................. 21

Engine Oil Cooler............................................. 18

Engine Oil Filter Base...................................... 17

Engine Oil Pan................................................. 22

Front sealant................................................ 22

Rear sealant................................................. 22

Engine Oil Pressure......................................... 21

M

Main Bearing Journal (Spheroidal Graphite

Iron (SGI) Crankshaft).................................... 27

The Shell for the Main Bearings................... 27

P

Piston and Rings ............................................. 29

Piston........................................................... 30

Piston Cooling Jet............................................ 30

This document has been printed from SPI2. NOT FOR RESALE.

![]()

42

UENR4460

Index Section

Piston Cooling Jet Alignment....................... 30

R

Refrigerant Compressor.................................. 35

Rocker Shaft.................................................... 10

S

Specifications Section ....................................... 4

Speed/Timing Sensor...................................... 38

Starter Motor.................................................... 36

12 V Starting Motor 3 kW, 4 kW, and 24 V

Starting Motor 4.5 kW................................. 37

T

Table of Contents............................................... 3

Turbocharger................................................... 14

V

Valve Mechanism Cover..............................., ... 12

W

Water Pump..................................................... 24

Water Temperature Regulator and Housing.... 24

This document has been printed from SPI2. NOT FOR RESALE.

![]()

400-082-9096

0731-84424871 18374999699

0731-84424872 15580888444

0731-84424873 18274802060

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska